Capacity electricity loaded hydraulic pump testing device

A test device and hydraulic pump technology, which is applied in the direction of pump testing, liquid variable displacement machinery, machine/engine, etc., can solve the problems of difficult loading control, complex mechanical structure, and difficult installation, so as to reduce the installed capacity and adapt to the scope Great, easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The detailed description and technical content of the present invention are described below with the accompanying drawings, but the accompanying drawings are only provided for reference and description, and are not intended to limit the present invention.

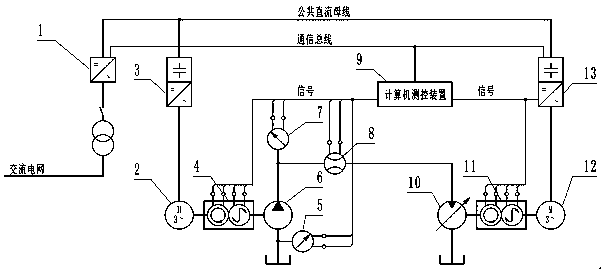

[0018] Refer to attached figure 1 According to the function, it can be divided into five parts: the tested hydraulic pump and its driving part, hydraulic pump-motor part, motor loading part, frequency conversion motor and AC dynamometer electric drive and control part, computer measurement and control device.

[0019] The pump under test and its driving part include the frequency conversion motor 2 for driving the pump under test and the inverter device 3 for the frequency conversion motor for driving the pump under test, the torque speed sensor 4, the hydraulic pump under test 6. This part provides mechanical energy for the tested hydraulic pump. The rotational speed of the tested hydraulic pump 6 is precisely cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com