Slag falling system of garbage boiler

A technology for boilers and slag removal, applied in incinerators, combustion types, combustion methods, etc., can solve the problems of poor slag moving ability, increasing the difficulty of slag removal, and clogging of slag openings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

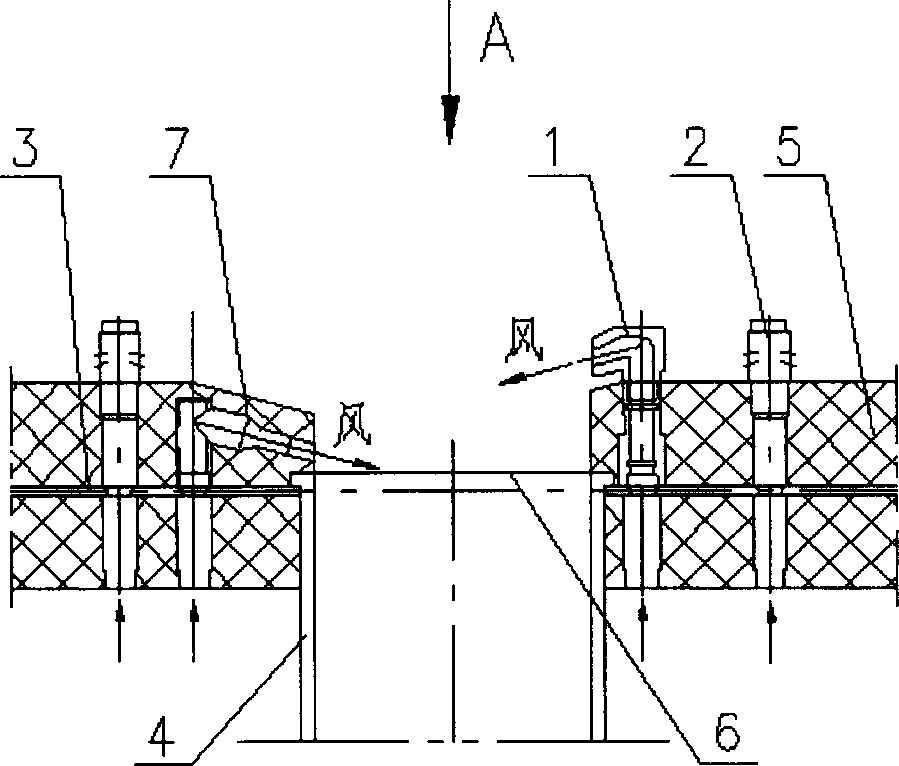

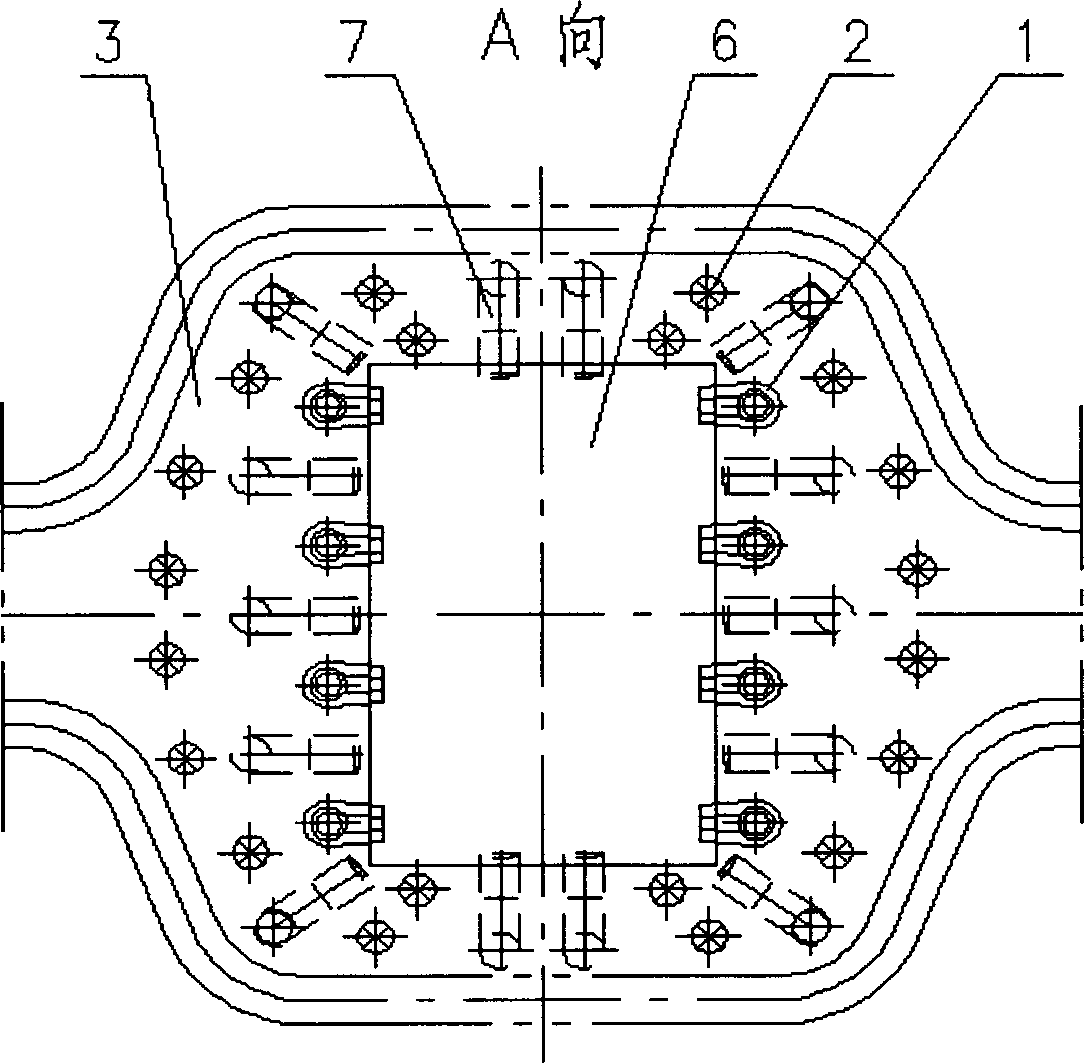

[0014] A garbage boiler slag removal system, comprising a square mouth directional air cap 1, a mushroom-shaped air cap 2, an air distribution plate 3, a slag removal pipe 4, a pouring material 5, and a slag outlet 6, and is characterized in that it also includes a duckbill-shaped directional air cap 7. Duckbill-shaped directional hood 7, square-mouth directional hood 1, and mushroom-shaped hood 2 are layered on the outside of the slag outlet 6 from inside to outside. The position near the slag outlet 6 forms a stepped shape with an up and down drop. The mushroom-shaped hood 2 is arranged outside the slag outlet, and the duckbill-shaped directional hood 7 is completely buried in the castable 5. Type hoods 2 stretch out from the surface of castable 5, and all hoods are vertically inserted into the openings of the air distribution plate 3.

[0015] The shape of the air outlet of the duckbill-shaped directional air cap 7 is oblate, similar to a duckbill, and the downward inclinat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com