Device and method for graphite electric hot plate temperature control

A temperature control device and control method technology, applied in the direction of temperature control, non-electric variable control, control/regulation system, etc., can solve the problems of limited temperature measurement range, inaccurate temperature measurement, simple temperature control algorithm, etc., to achieve temperature control Short balance time, improved service life, and accurate temperature control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

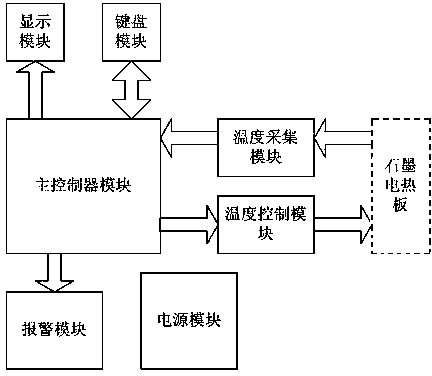

[0027] Depend on figure 1 It can be seen that the present invention is composed of a main controller module, a temperature acquisition module, a temperature control module, a button module, a display module, an alarm module, and a power supply module. The main controller module adopts the enhanced C8051F410 chip as the controller, and performs the functions of temperature acquisition, temperature control, key setting, temperature information display and alarm.

[0028] figure 2 It is the schematic diagram of the circuit of the main controller module of the present invention, in which the C8051F410 chip is a single-chip microcomputer; R22 and C12 form a reset circuit, and the RESET reset signal is connected to the second pin of the C8051F410 chip; FM24C02 is a memory chip, and SCL and SDA are signal lines, respectively Connect the 20th and 19th pins of C8051F410, FM24C02 and R41, R42 and C15 form the storage unit of the main controller to realize the storage of setting inform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com