Dry type transformer for deepwater

A dry-type transformer and transformer technology, applied in the field of transformers, can solve problems such as incompatibility, and achieve the effects of improving conversion efficiency, effectively utilizing space, and reducing overall volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

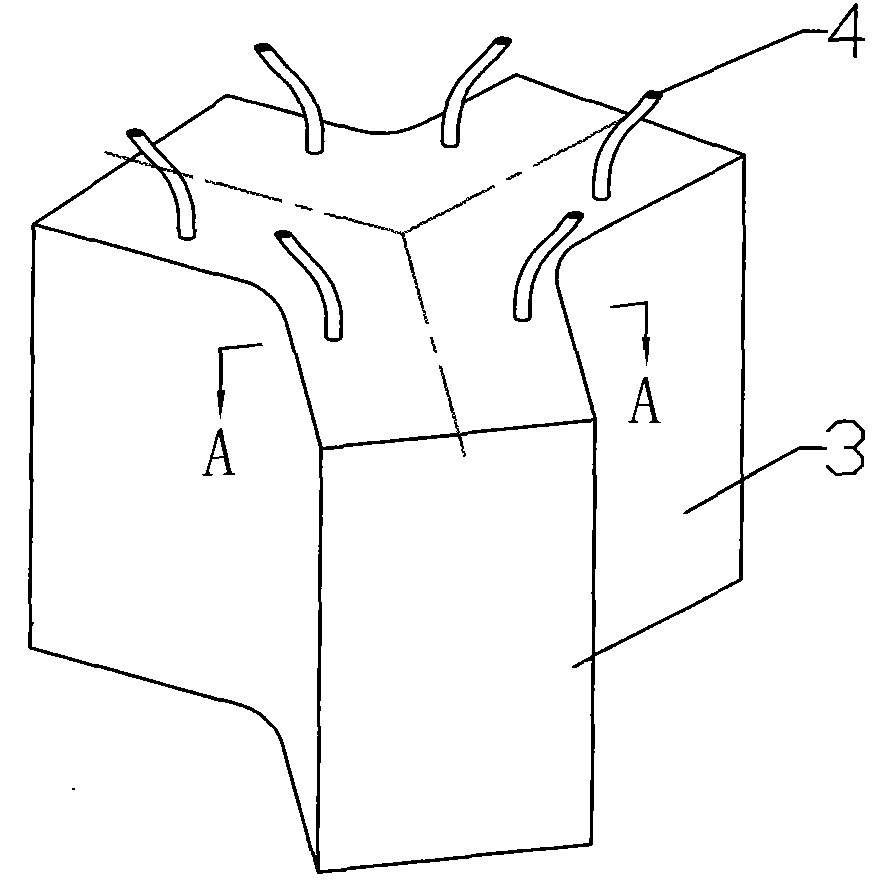

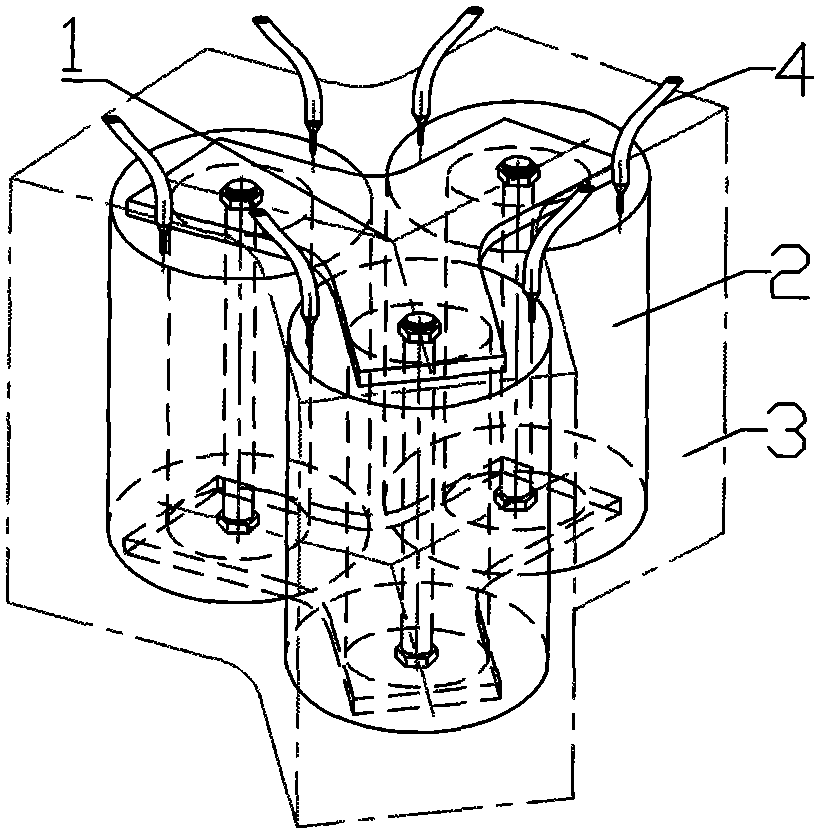

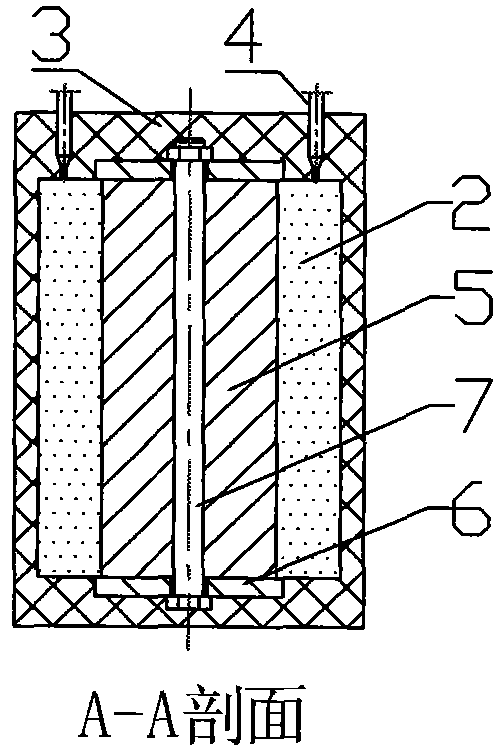

[0018] Such as Figure 6 and Figure 8 As shown, the three columnar rolled iron cores 5 are rolled with amorphous alloy coils, and a through hole 8 is arranged in the center of the rolled iron core 5;

[0019] Such as Figure 5 and Figure 7 As shown, the two yokes 6 are both Y-shaped and made of magnetically permeable plates. The centerlines of the three protrusions of the yoke 6 form an angle of 120 degrees to each other, and a circle is arranged on each protrusion. hole;

[0020] Such as Figure 4 As shown, three rolled iron cores 5 are clamped between two yoke irons 6, and the screws 7 sequentially pass through the round holes on the lower yoke iron 6, the through holes 8 on the rolled iron core 5 and the holes on the upper yoke iron 6. round hole, and fastened with a nut to form the iron core body 1.

[0021] Such as figure 2 As shown, the three coil windings 2 are respectively set on the three rolled iron cores 5 of the iron core body 1, and the lead wires of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com