Method for manufacturing three-dimensional through hole interconnection structure based on molten glass skeleton

A technology of molten glass and three-dimensional through-holes, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of weak insulation performance of the growth layer, poor reliability, and difficult electroplating process processing, etc. Simplified process steps and good electrical connection reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

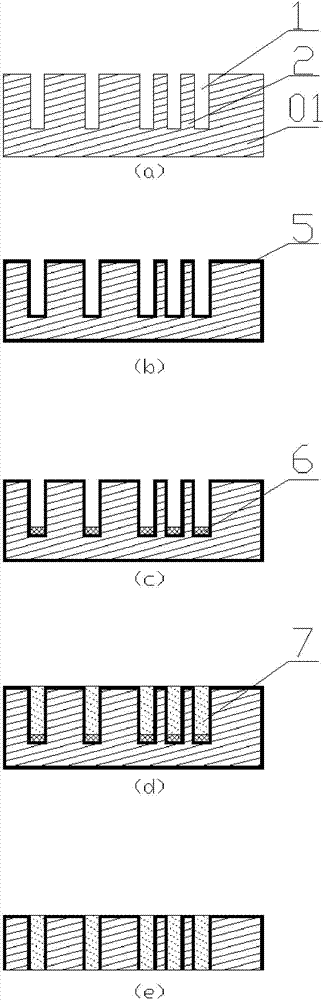

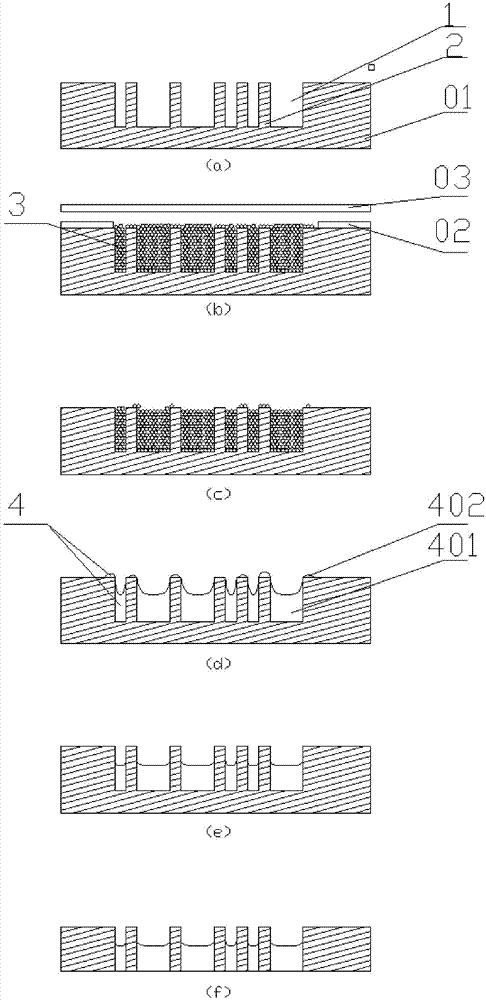

[0024] see figure 2 , the manufacturing process of the embodiment of the three-dimensional through-hole interconnection structure based on the molten glass skeleton according to the present invention includes the following steps:

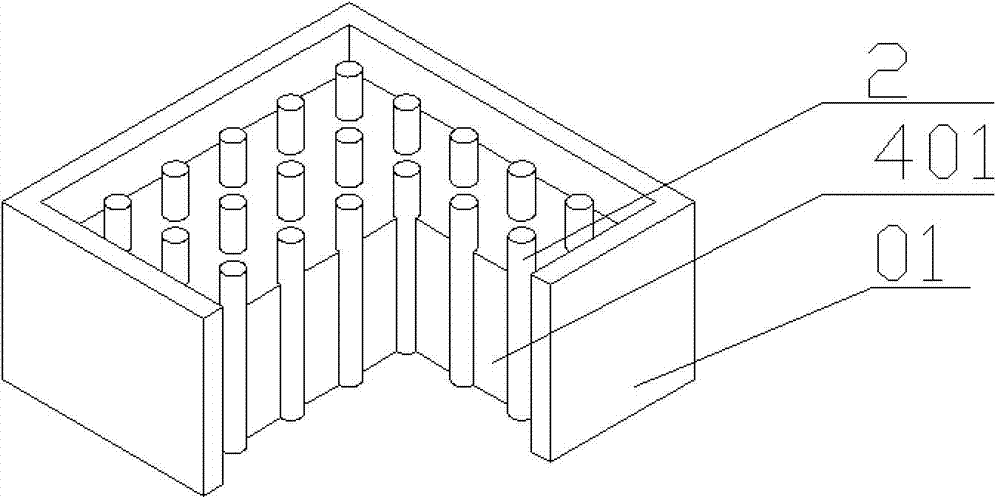

[0025] 1) On the silicon wafer 01, the combined process of photolithography and DRIE is used to process the groove 1 and the silicon pillar 2, such as figure 2 as shown in (a);

[0026] 2) Use the screen plate 02 with a hollow pattern and a thickness of 200 μm to align it with the silicon wafer 01 to ensure that the hollow pattern is aligned with the silicon pillar area of the silicon wafer 01, while the rest of the silicon wafer 01 is protected by the screen plate . Select nano-glass powder 3 (melting point 530°C, thermal expansion coefficient 4.0) and place it in the screen plate 02, use flat plate 03 to reciprocate in the vertical direction, repeatedly squeeze nano-glass powder 3, so that the groove is completely filled with nano-glass powd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com