Early-stage and medium-stage granulum fodder for broiler chicken and preparation method of same

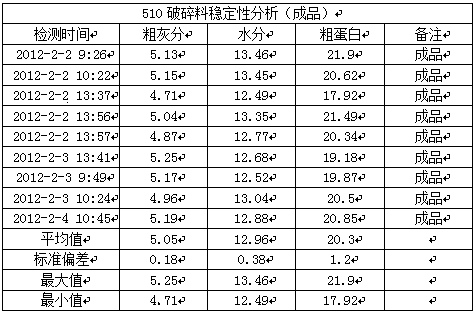

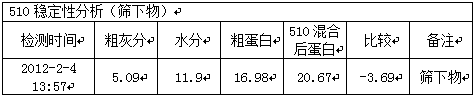

A broiler, small particle technology, applied in animal feed, animal feed, application, etc., can solve the problem of unstable quality of crushed material, and achieve the effects of improving appearance stability, low component variation coefficient, and high elimination rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] A method for producing small granules in the early growth period (510) of broilers, the preparation steps comprising:

[0053] Batching steps: mix ingredients accurately according to the formula;

[0054] Granulation steps: Use 420 stainless steel ring die, ¢2.0mm, compression ratio 1:5-8, granulate at 70-85°C to make the degree of gelatinization reach 90%, adjust the position of the cutter of the granulator, and control the product The length is 0.5-1.0d;

[0055] Cooling step: After granulation, the granules are cooled, and the temperature difference between the finished material temperature and room temperature is ≤5°C;

[0056] Classification steps: the upper sieve of the grading sieve is 6-10mm, and the bottom sieve of the grading sieve is 1.5-1.8mm. Start the sieve screening during the granulation process;

[0057] Finished product packaging: finished product hardness 1-2.0kg.

Embodiment 2

[0059] A method for producing crushed feed for broiler chickens in the early growth period (510), the preparation steps comprising:

[0060] Batching steps: mix the ingredients accurately according to the 510 formula;

[0061] Granulation steps: Use 420 stainless steel ring die, ¢3.0mm, compression ratio 1:5-10, granulate at 70-85°C to make the gelatinization degree reach 90%;

[0062] Cooling step: After granulation, the granules are cooled, and the temperature difference between the finished material temperature and room temperature is ≤5°C;

[0063] Crushing step: adjust the gap between the rollers of the granulator, and adjust the crushing particle size of the finished product to 1.5-3.0mm;

[0064] Classification steps: the upper sieve of the grading sieve is 3mm, and the bottom sieve of the grading sieve is 1.5-1.8mm. The sieve sieving is started during the granulation process.

[0065] Finished product packaging: finished product particle size 1.5-3.0mm.

Embodiment 3

[0067] A method for producing small pellets for broilers in the mid-growth period (511), the preparation steps of which include:

[0068] Ingredients step: Mix the ingredients accurately according to the 511 formula;

[0069] Granulation steps: Use 420 stainless steel ring die, ¢2.0mm, compression ratio 1:5-10, granulate at 70-85°C to make the degree of gelatinization reach 90%, adjust the position of the cutter of the granulator, and control the product The length is 1.0-2.0d;

[0070] Cooling step: After granulation, the granules are cooled, and the temperature difference between the finished material temperature and room temperature is ≤5°C;

[0071] Classification steps: the upper sieve of the grading sieve is 6-10mm, and the bottom sieve of the grading sieve is 1.5-1.8mm. The sieve sieving is started during the granulation process.

[0072] Finished product packaging: finished product hardness 2.0-3.0kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com