Device and method for stably adding sludge in sintering

A sludge and stabilization technology, applied in chemical instruments and methods, mixer accessories, mixers, etc., can solve problems such as sintering production fluctuations, impurities, and easy precipitation, etc., to increase the amount of sludge added, reduce costs, and improve The effect of active ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

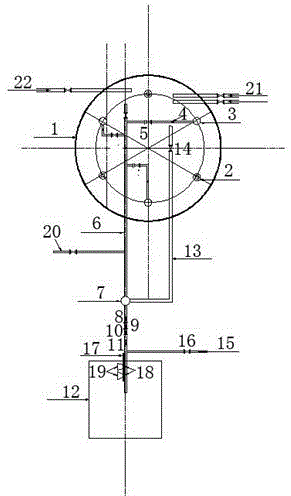

[0044] The converter mud is transported to the mud mixing tank by two mud supply pipelines from the power plant, and the mud concentration is controlled at 16%-22%. In order to avoid pipeline blockage caused by high mud concentration, the production water in the factory is replenished through the water supply pipeline to dilute the mud to meet the normal production needs.

[0045] The mud mixing pool has a diameter of 8 meters and a depth of 3 meters, of which the underground part is 2.8 meters and the above-ground part is 0.2 meters. The awning is built on it. The liquid level of the mud pool is kept at 1.8-2.2 meters in normal use. No less than 2 times to get mud in the class; 360m 2 The sintering machine can use about 150t of mud per day.

[0046] The equipment on the mud mixing tank platform includes 3 sets of mud pumps, model 50YZ36-50, power N=22KW / set, two open and one standby; 3 sets of mixing pumps, model Y160L-4, power N=15KW / set, fully open. The mud conveying capa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com