Homogeneous molybdenum base epoxidation catalyst

A catalyst, epoxidation technology, applied in the direction of physical/chemical process catalyst, organic compound/hydride/coordination complex catalyst, organic chemistry, etc., can solve the problem of low selectivity of propylene oxide, cumene hydrogen peroxide Problems such as low conversion rate, to achieve the effect of high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

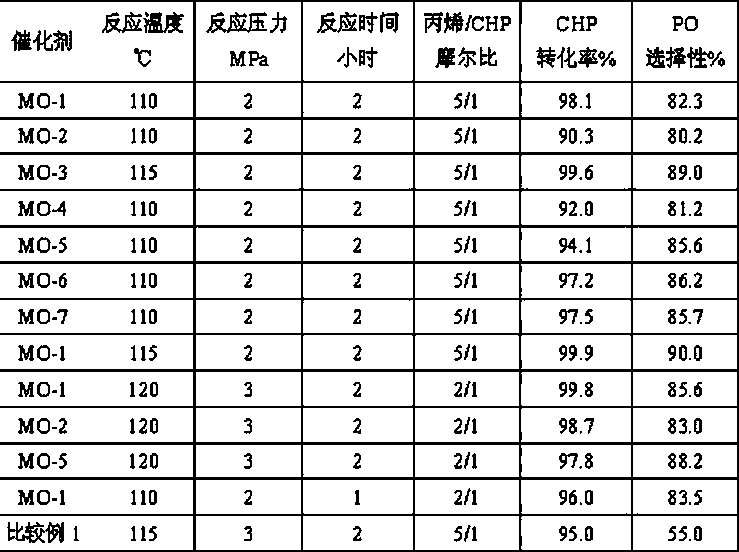

Examples

Embodiment 1

[0018] Get 2.88 grams of commercial grade molybdenum oxide, add 30 grams of isooctanoic acid and 20 grams of cumene, stir at room temperature for 1 day, the molybdenum compound gradually dissolves, and the color of the mixture gradually changes from bright yellow to brown; then add 2.4 grams of hexadecylamine and heat to 160°C, magnetically stirred for 12 hours; then 0.2 g of sodium naphthenate was added and stirred for 0.5 hours to obtain a homogeneous organomolybdenum catalyst MO-1. Among them, in MO-1, the molybdenum content is 3.4% by weight based on molybdenum.

[0019]

Embodiment 2

[0021] Get 2.88 grams of commercial grade molybdenum oxide, add 30 grams of isooctanoic acid and 20 grams of cumene, stir at room temperature for 1 day, the molybdenum compound gradually dissolves, and the color of the mixture gradually changes from bright yellow to brown; then add 0.24 grams of hexadecylamine and heat to 160°C, magnetically stirred for 12 hours; then 0.2 g of sodium naphthenate was added and stirred for 0.5 hours to obtain a homogeneous organomolybdenum catalyst MO-2. Wherein, in MO-2, the molybdenum content is 3.6% by weight based on molybdenum.

[0022]

Embodiment 3

[0024] Take 2.88 grams of commercial grade molybdenum oxide, add 20 grams of isooctanoic acid, 10 grams of hydrochloric acid and 20 grams of cumene, stir at room temperature for 1 day, the molybdenum compound gradually dissolves, and the color of the mixture gradually changes from bright yellow to brown; then add 0.24 grams of sixteen Amine, heated to 170°C, magnetically stirred for 12 hours; then 0.2 g of sodium naphthenate was added and stirred for 0.5 hours to obtain a homogeneous organic molybdenum catalyst MO-3. Wherein, in MO-3, the molybdenum content is 4.5% by weight based on molybdenum.

[0025]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com