Rapid indexing device

A rapid indexing and indexing plate technology, applied in metal processing machinery parts, precision positioning equipment, metal processing equipment, etc. The problem of high cost, which is beneficial to storage management, simple structure and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

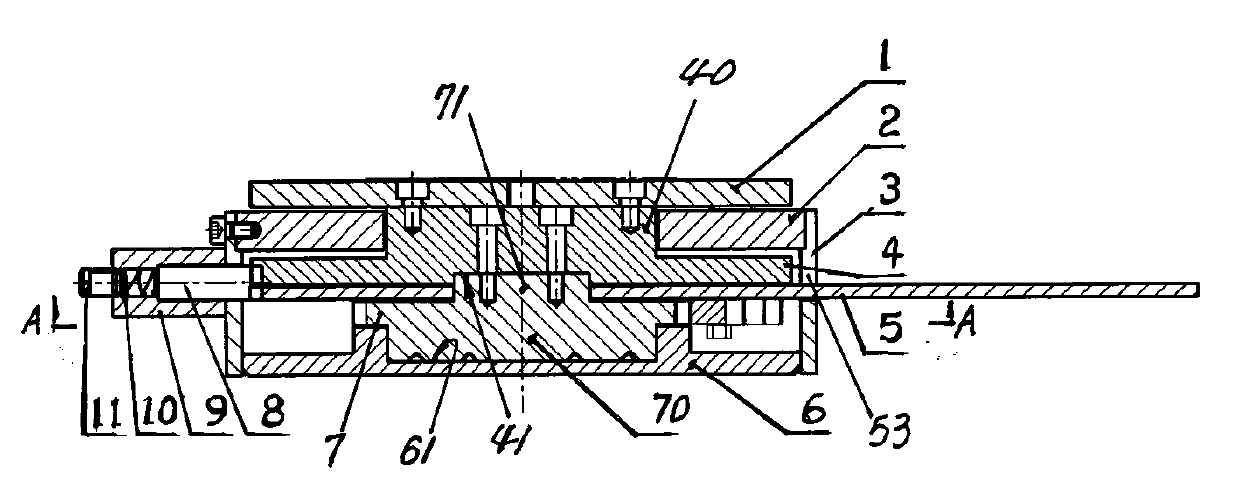

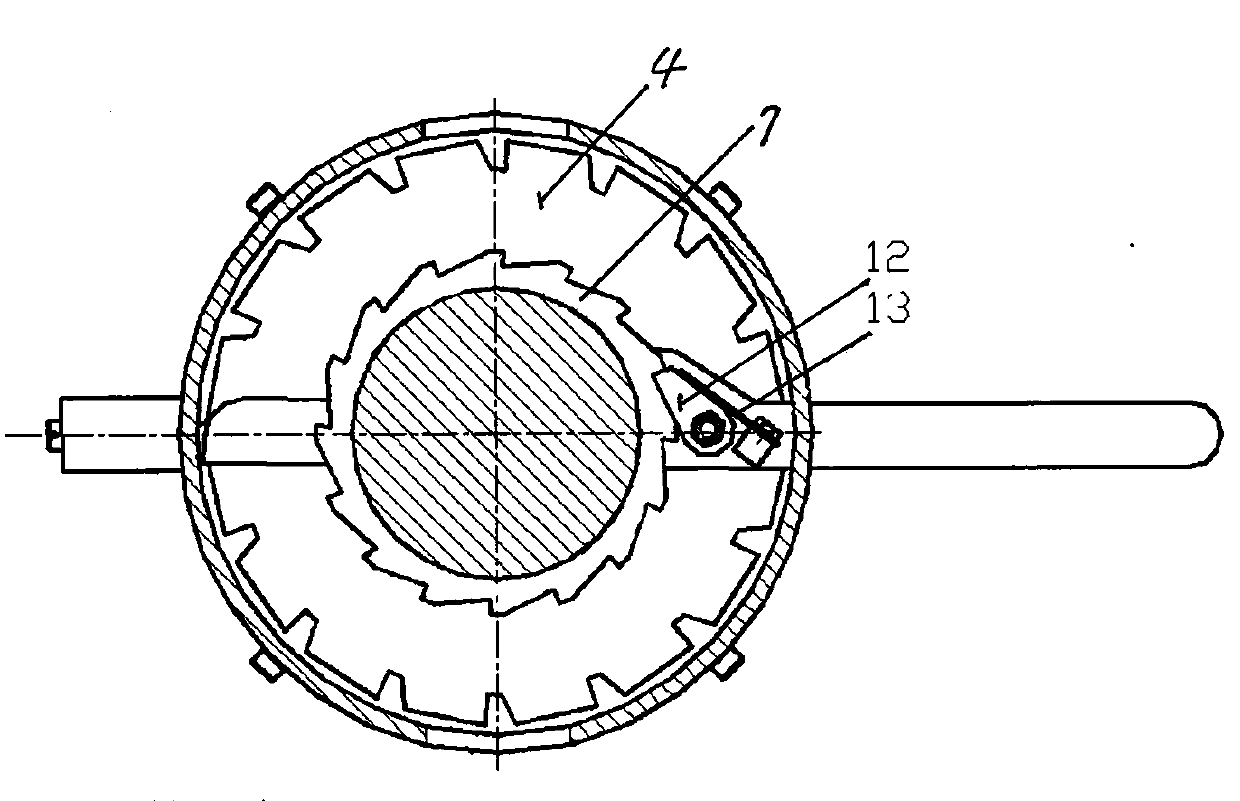

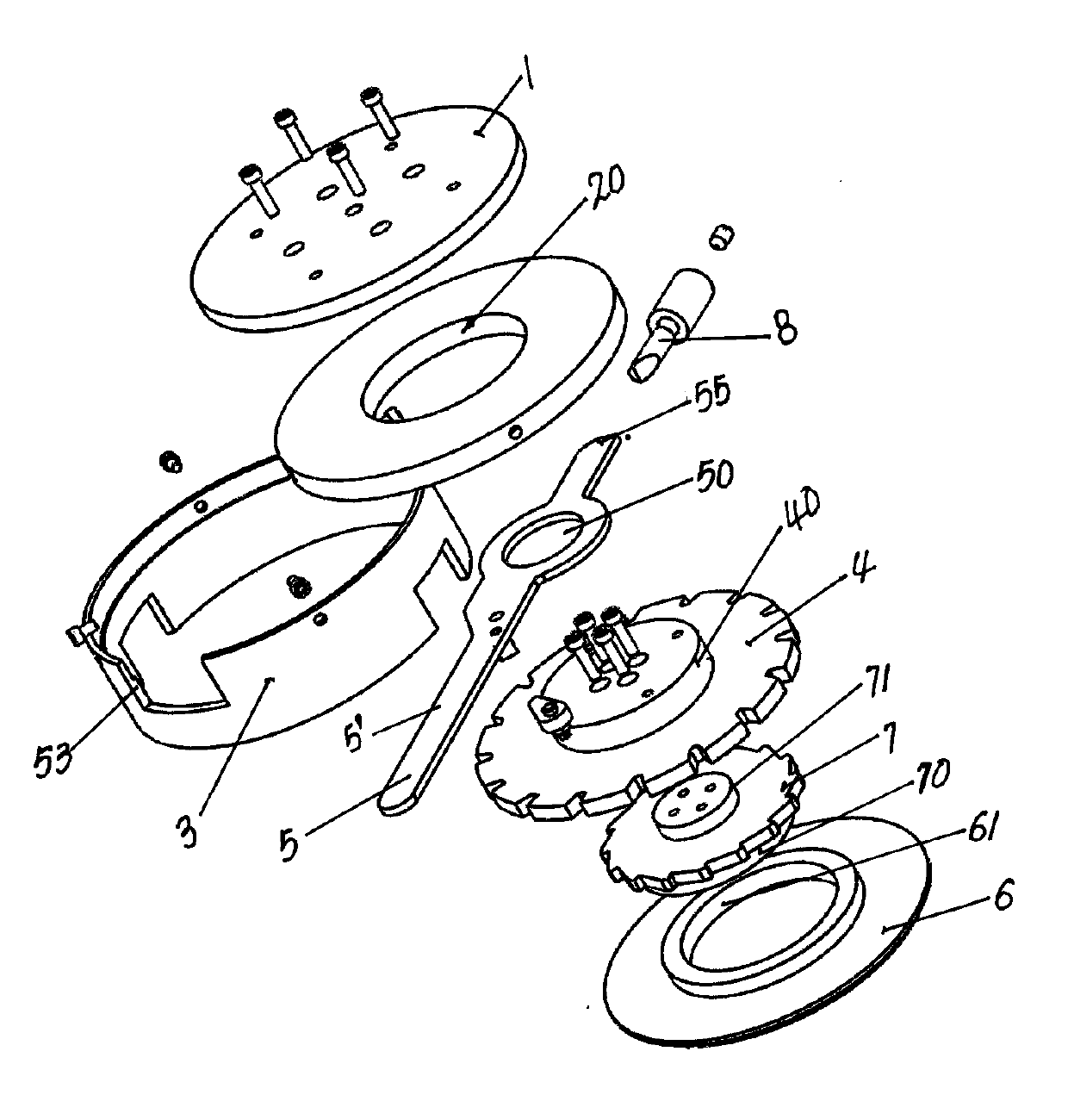

[0015] The present invention consists of an index plate 1, an upper cover 2, a housing 3, an upper toothed plate 4, a wrench 5, a base 6, a lower toothed plate 7, a positioning head 8, a positioning tube 9, a compression spring 10, a top wire 11, and a pawl 12. Composed of spring sheets 13, the base 6 is welded to the bottom of the housing 3, the positioning tube 9 is welded to the side of the housing 3, and an annular concave platform 61 is provided in the middle of the upper end surface of the base 6, and the lower end of the lower tooth plate 7 There is a central cylindrical boss 70 and the ring-shaped recess 61 on the base 6 for sliding and rotating installation, and a cylindrical boss 71 is provided at the center of the upper end surface of the lower toothed disc 7, and a shaft hole 50 is opened on the wrench 5 and the lower toothed disc 7 The cylindrical boss 71 on the end face is connected by rotation and fit, and the corresponding wrench 5 is provided with a notch 53 on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com