Descaling system

A scale and water softening device technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of difficult scale removal, restricting coal mine production, and excessive operating resistance. , to avoid abnormal gas at the extraction site or stop production of the working face, reduce labor and maintenance costs, and prolong the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

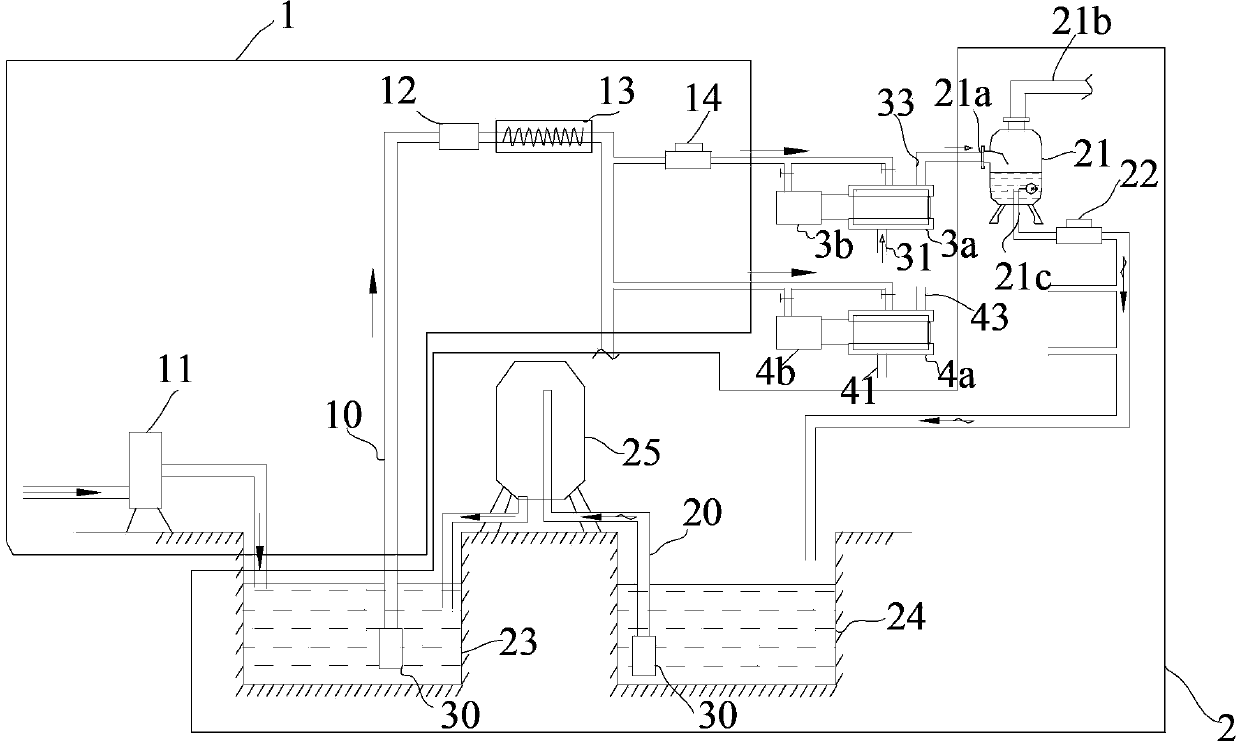

[0019] Such as Figure 1-3 As shown, the embodiment of the present invention provides a descaling system, which at least includes a water inlet descaling system 1; the water inlet descaling system 1 includes: a water filter 11, a cold water pool 23, and a centrifugal pump 12 connected in sequence through pipelines 1. Scale remover 13 and first water softening device 14; The water filter inlet is connected to the water source; The water filter outlet and the centrifugal pump inlet are all communicated with the cold water pool 23, and the centrifugal pump inlet is located at the bottom of the cold water pool 23 in the present embodiment, and the centrifugal pump The outlet is connected to the inlet of the automatic scale remover; the inlet of the first water softening device is connected to the outlet of the scale remover, and the outlet of the first water softening device is connected to the water inlet of the water ring vacuum pump.

[0020] In this embodiment, there are two v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com