An optical glass furnace melting pool

An optical glass and melting pool technology, applied in furnaces, retort furnaces, furnace types, etc., can solve the problems that the selection of heating methods cannot guarantee the quality of special glass, high glass property parameters and inherent quality requirements, and wide glass formulation system. , to achieve the effect of broadening the production range, increasing the daily production and improving the quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

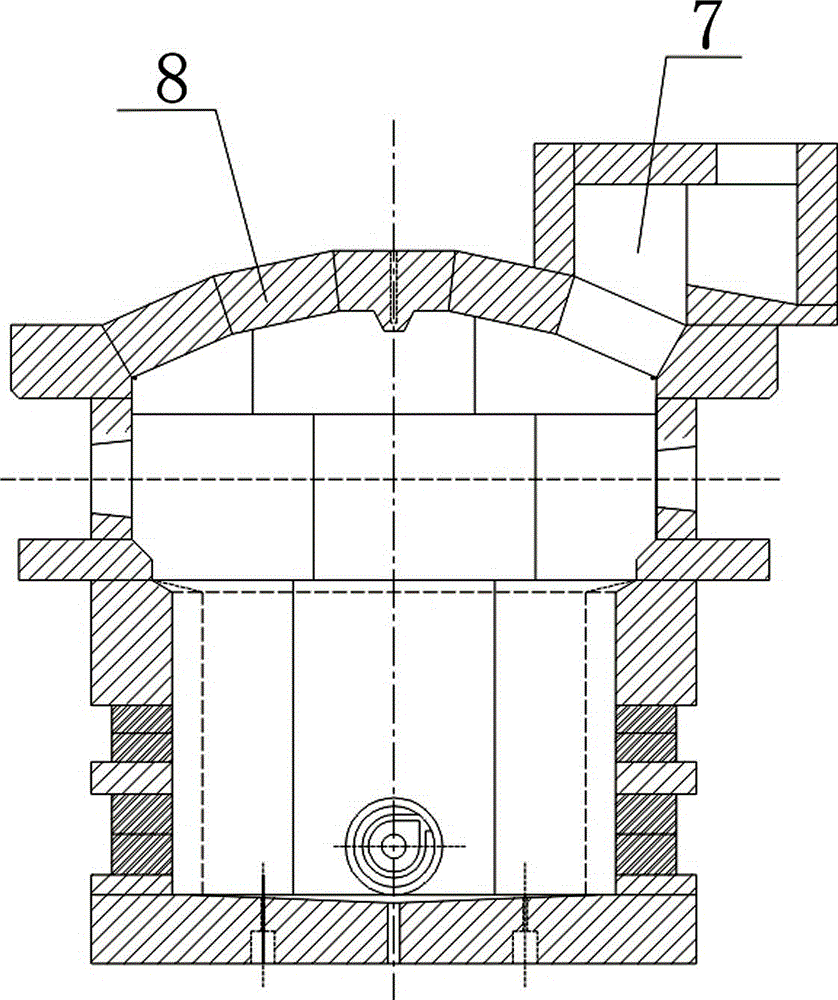

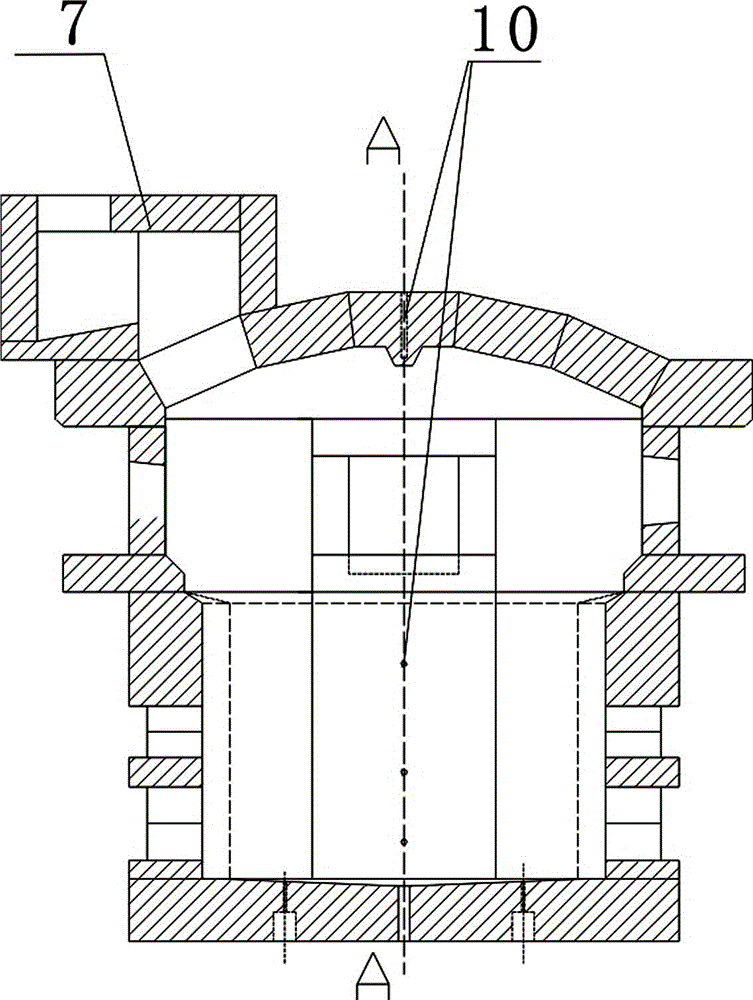

[0023] Such as Figure 1~Figure 5 As shown, a melting tank of an optical glass furnace includes a cover brick 8, a wall brick 3 and a bottom brick 6, and the cover brick 8, wall brick 3 and bottom brick 6 form a hollow melting tank body from top to bottom. Cover brick 8, wall brick 3 and bottom brick 6 are all made of fused zirconia corundum bricks.

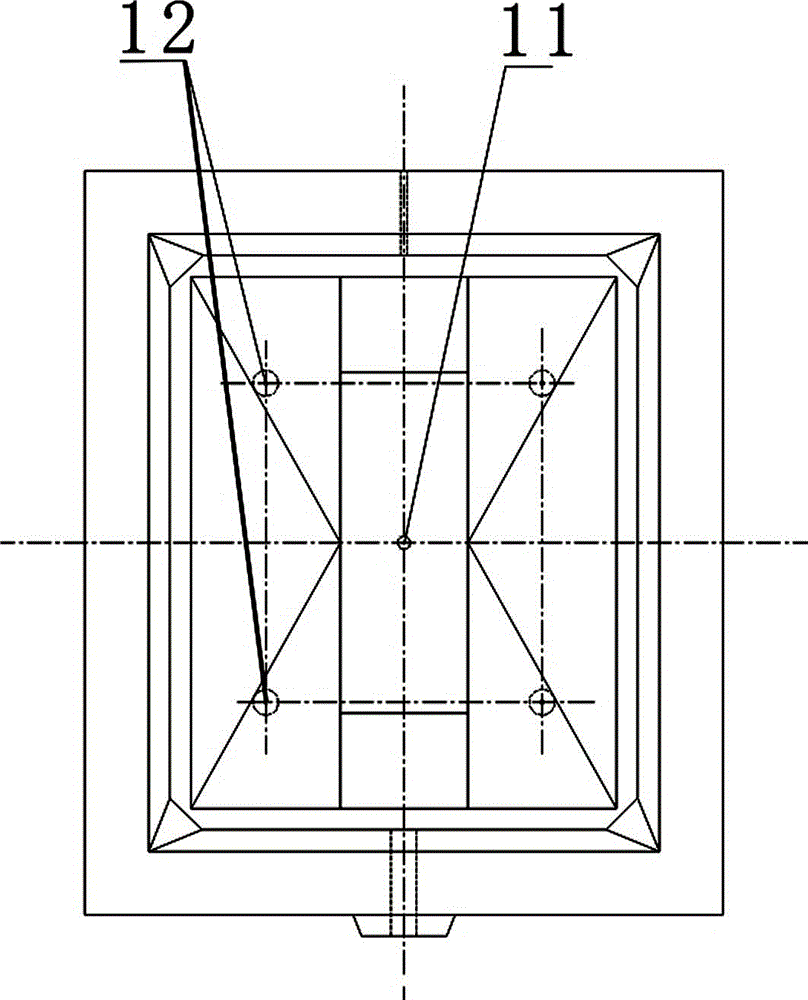

[0024] The melting pool of the present invention is square, with an area of 0.95-1.92 square meters and a depth of 0.78-0.98 meters. The upper part of the main body of the melting pool is provided with a material inlet 2 and the bottom is provided with a material outlet 13 . The bottom of the main body of the melting pool is provided with four bubblers 12 with a diameter of 8 mm. 3 burning guns 1 are distributed on the upper part of the melting pool, fuel: natural gas, liquefied gas, etc.

[0025] A plurality of temperature measuring holes 10 are arranged on the main body of the melting pool, and thermocouples are installed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com