A preparation process for producing biodiesel from refined oil

A preparation process, biodiesel technology, applied in the petroleum industry, biofuel, fatty acid esterification, etc., can solve the problems of weak adaptability and compatibility of raw materials, unstable product quality, unstable process, etc. The effect of wasting raw materials and stabilizing the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

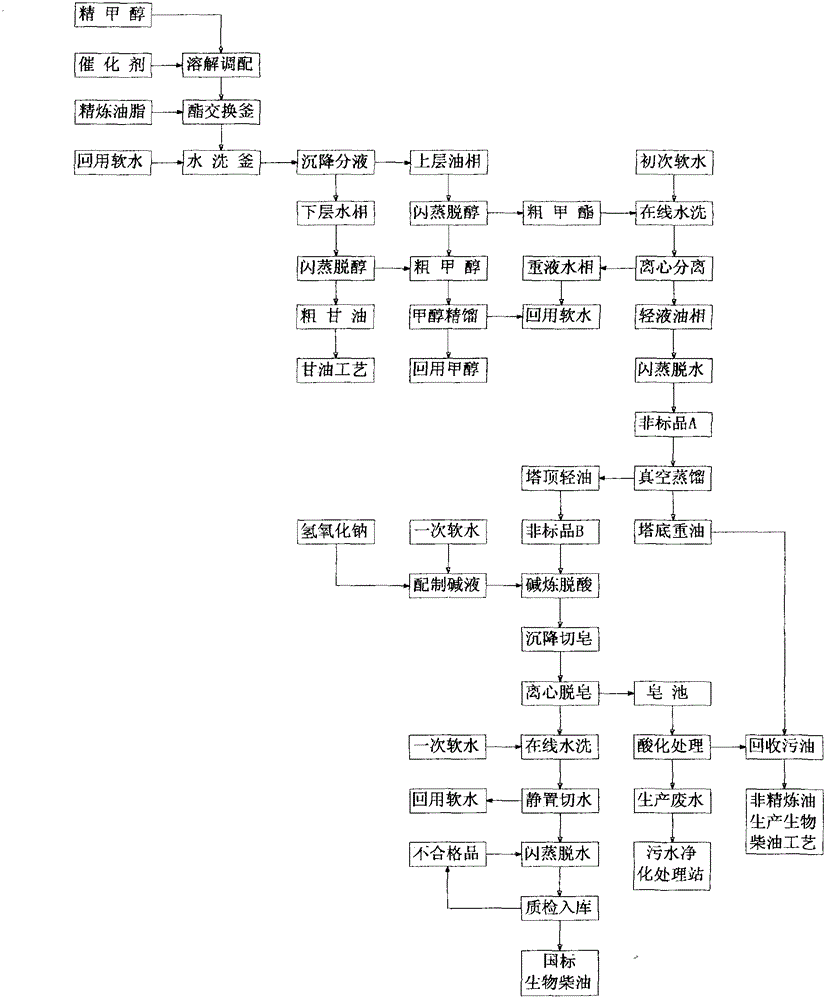

Image

Examples

Embodiment

[0033] Dissolve the oil in methanol with an oil mass percentage of 30% at a temperature of 50°C to 55°C, add 6.3% to 6.5% flake sodium hydroxide into the oil at a mass percentage of 55°C to 60°C, and stir with high-shear self-circulation for normal pressure esterification The exchange reaction takes 60 to 90 minutes. The transesterification reaction does not exceed the boiling point of methanol, and there are condensation and reflux measures to prevent the loss of methanol from changing the concentration of the material and aggravating side reactions. Afterwards, add 15% oil mass and soft water with a temperature of 45° C. to 55° C. (which can be recovered in the subsequent process) and stir for 5 minutes, and leave to stand for 60 minutes to fully separate layers and separate liquids. The crude methyl ester in the upper layer and the crude glycerol in the lower layer are dealcoholized by flashing, and the released methanol enters the methanol rectification tower for regenerat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com