Fixed-length weft accumulator control system and control method thereof

A control system and weft feeder technology, applied in textile, textile, papermaking, looms, etc., can solve the problems of slow acceleration and deceleration, high rotation speed, low weft insertion rate, etc., to improve production efficiency, facilitate installation and use, The effect of improving the weft insertion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

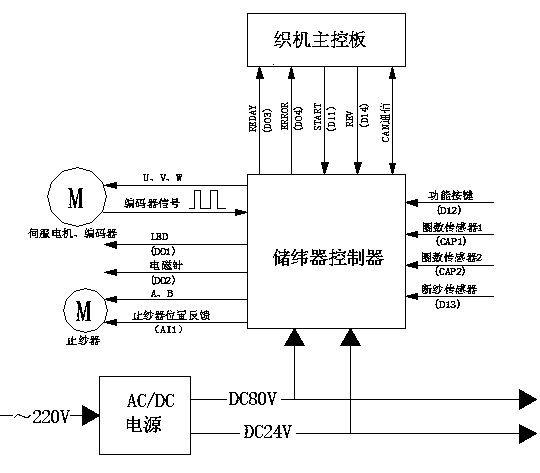

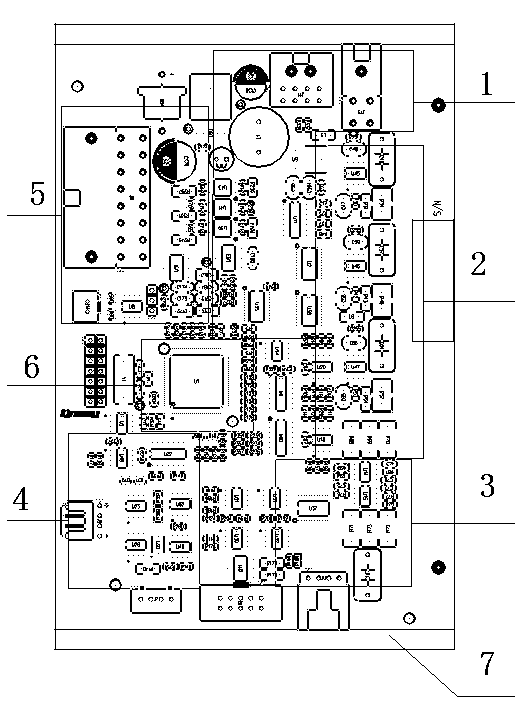

[0030] Such as figure 1 , 2 As shown, a fixed-length weft feeder control system, the control system includes at least one set of weft feeder control devices, the weft feeder control device includes a weft feeder controller, a weft storage motor electrically connected to the weft feeder controller , a yarn stopper and a detector for real-time monitoring of loom operating conditions, and the controller of the weft feeder is electrically connected to the main control board of the loom.

[0031] The weft storage motor is used to control the operation of the weft feeder. The weft storage motor is a high-speed AC servo motor. The high-speed AC servo motor has the characteristics of fast acceleration and deceleration, high speed, small size, easy installation and use, and energy saving and power saving. The production efficiency is greatly improved, and the cost of production and use is reduced.

[0032] The yarn stopper is used to adjust the tension of the yarn to avoid the phenom...

Embodiment 2

[0044] The rest is the same as that of Embodiment 1, except that multiple weft feeder control devices share the bus. The power supply method of multiple weft feeder control devices sharing the bus is more energy-saving and power-saving, and the production and use costs are reduced.

Embodiment 3

[0046] The rest are the same as those in Embodiment 1 or 2, except that the digital signal processing module is a 2808DSP chip. The use of 2808DSP chip makes the response speed of the control system faster, which improves the speed and precision of the entire control system. Under the condition of high-speed weft insertion, the violent fluctuation of weft insertion tension is avoided, and the tension of each weft yarn introduced into the shed remains uniform. So as to reduce weft insertion breakage and improve the quality of fabric.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com