Imitated stone slab with preset patterns containing different size grading raw materials and preparation method thereof

A technology of predetermined pattern and particle size grading, which is applied in the direction of manufacturing tools, furniture accessories, forming conveyors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The following describes the process of an imitation stone plate with a predetermined pattern containing raw materials of different particle size gradations and a manufacturing method according to an embodiment of the present invention.

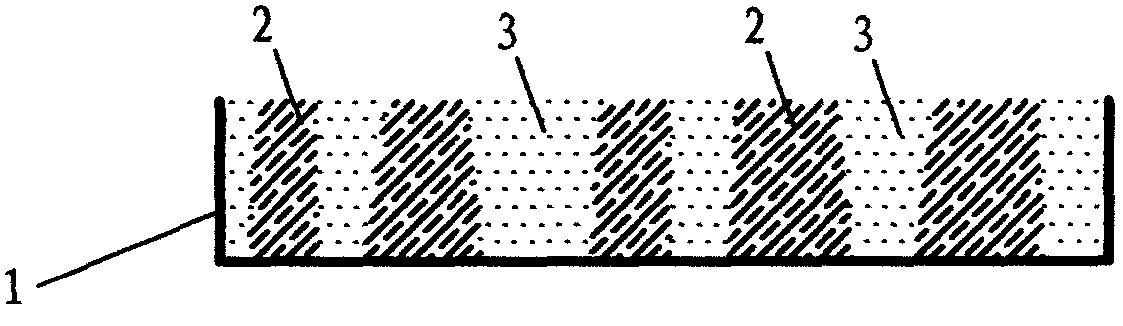

[0044] See figure 1 Shown is an embodiment of the imitation stone plate with different particle size grading materials in a predetermined pattern of the present invention and its production method. Two types of pattern materials with different colors and different particle sizes are distributed according to the predetermined pattern requirements through a predetermined cloth device. A schematic cross-sectional view of the loading mold frame. It can be seen from the figure that reference number 1 represents a predetermined size of 610×610mm loading mold frame; reference number 2 represents the first color zone pattern material of the product; reference number 3 represents the product second color zone pattern material.

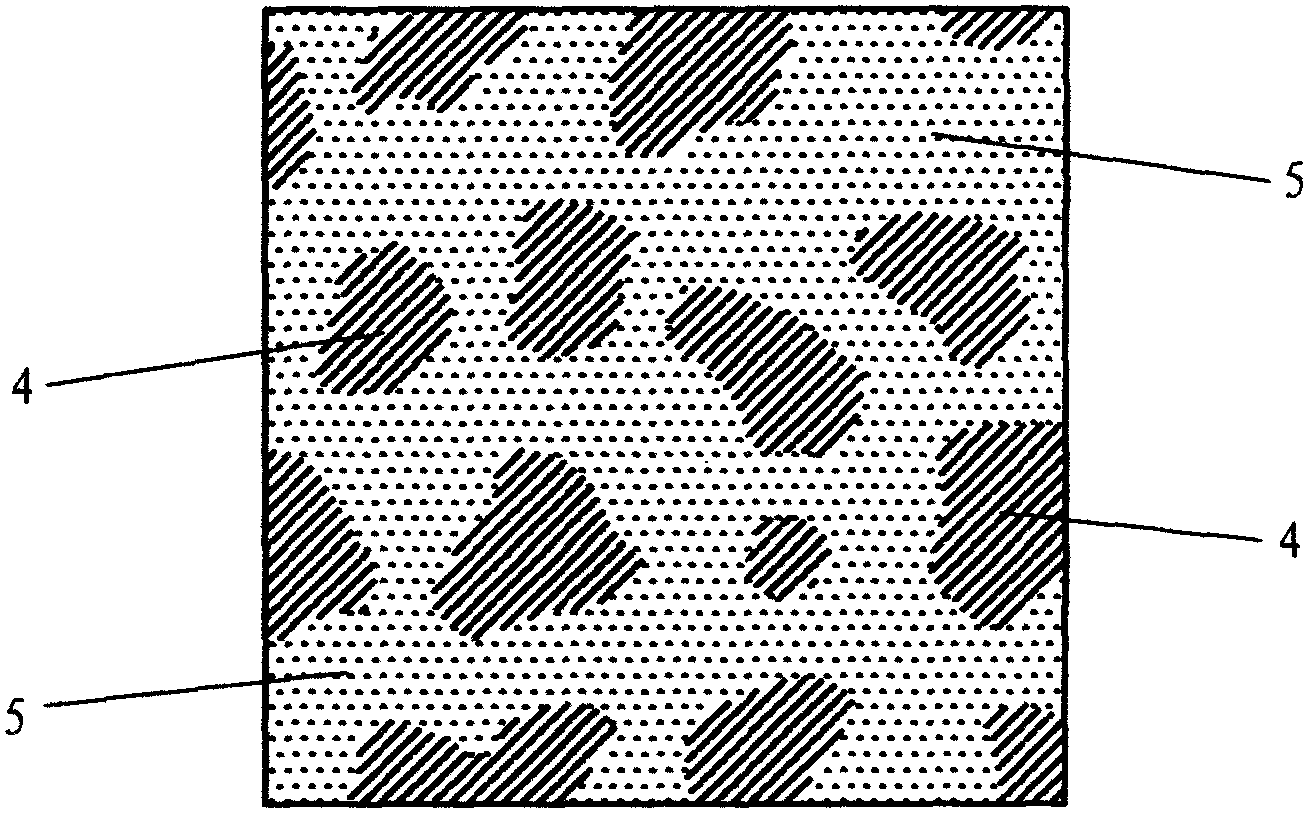

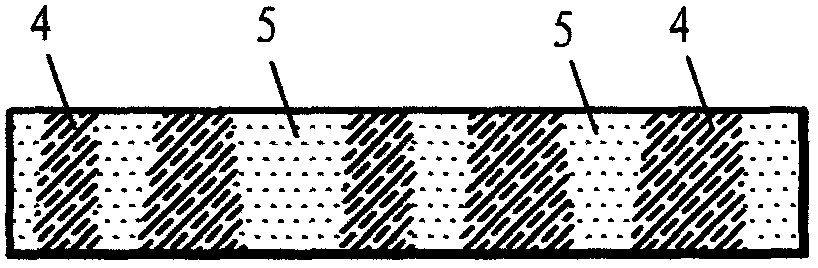

[0045] See figure 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com