Catwalk machine and catwalk device

A catwalk and track technology, applied in drilling equipment, earthwork drilling, drill pipe, etc., can solve the problems of large space occupation and low integration degree, and achieve the effect of increasing functions, improving transportation efficiency and increasing safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

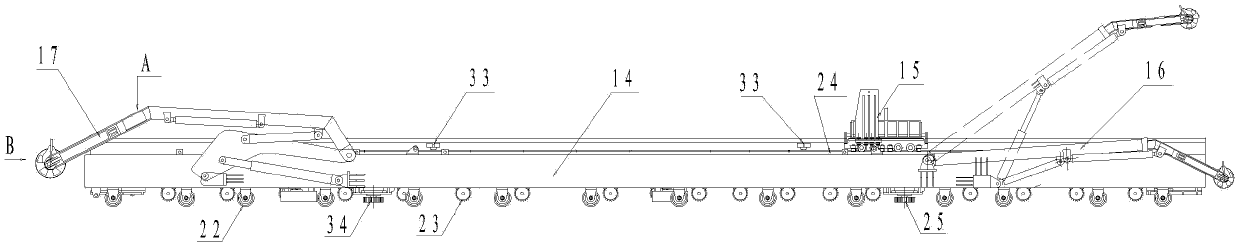

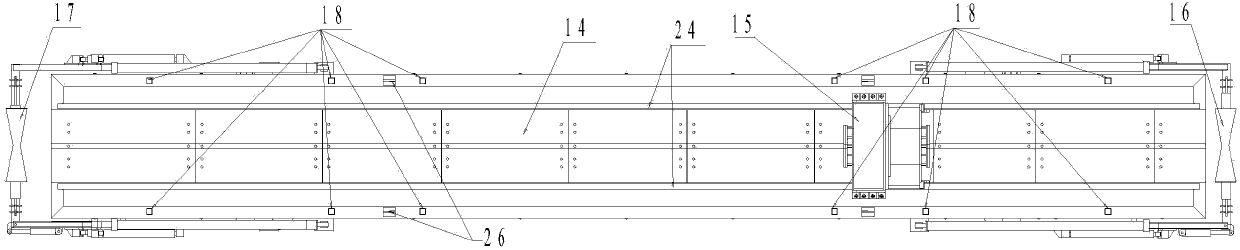

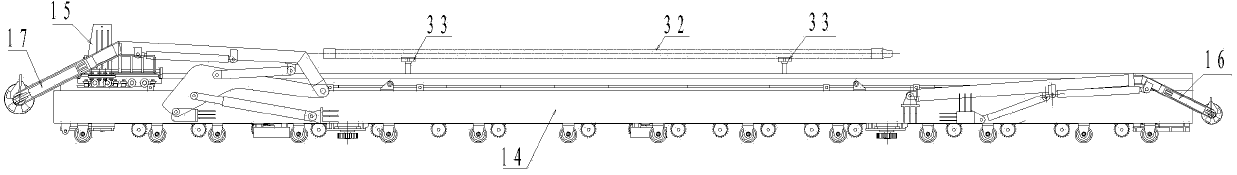

[0054] A catwalk machine 1, such as figure 1 , 2 As shown, it consists of a mobile frame 14, a double-sided trolley 15, a riser support vehicle 30, a drill pipe centralizing arm 16, a riser centralizing arm 17 and a control system 6, wherein the double-sided trolley 15, the drill pipe centralizing arm 16, Riser righting arms 17 are all installed on the mobile frame 14, and the control system 6 can control the movement of the mobile frame 14; the mobile frame 14 is provided with a supporting plate 33, which is scalable in height, and is convenient for pulling the drill pipe 32 from the catwalk machine 1 on and off, such as image 3 As shown, the riser support vehicle 30 is detachably installed on the mobile frame 14, and is installed on the mobile frame 14 when transporting the riser 11 into and out of the drill floor, as shown in Figure 4 Shown; The mobile frame 14 is also provided with a transportation platform 29, which is detachably installed on the mobile frame 14 thro...

specific Embodiment 2

[0059] A catwalk device such as Figure 10 , 11 12, in addition to the catwalk machine 1 in the specific embodiment 1, it also includes the drill floor surface 2 and the track 4, the track 4 extends along the two ends of the drill floor surface 2, and the two ends of the track 4 are respectively storage for drill pipes. In the storage area and the riser storage area, there are two racks in the track 4, namely rack one 5 and rack two 35, which are symmetrically distributed on both sides of the drill floor surface 2, and the catwalk machine 1 is also provided with gears One 25 and two gears 34 are all adapted to one 5 or two 35 of racks.

[0060] Since the general deep-sea drilling equipment is a semi-submersible platform or located on a drilling ship, the drill pipe 32 is usually arranged on one side of the drill floor 2, the riser 11 is arranged on the other side of the drill floor 2, and the drill pipe 32 or spacer on both sides Water pipe 11 is to lay flat. In view of thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com