Membrane type magneto-rheological damper and system

A magnetorheological damper, membrane technology, used in shock absorbers, shock absorbers, springs/shock absorbers, etc., can solve the problems of difficult damping and vibration reduction, affecting the running state of test results, and large piston mass. , to achieve the effect of small inertia, light weight and stable stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

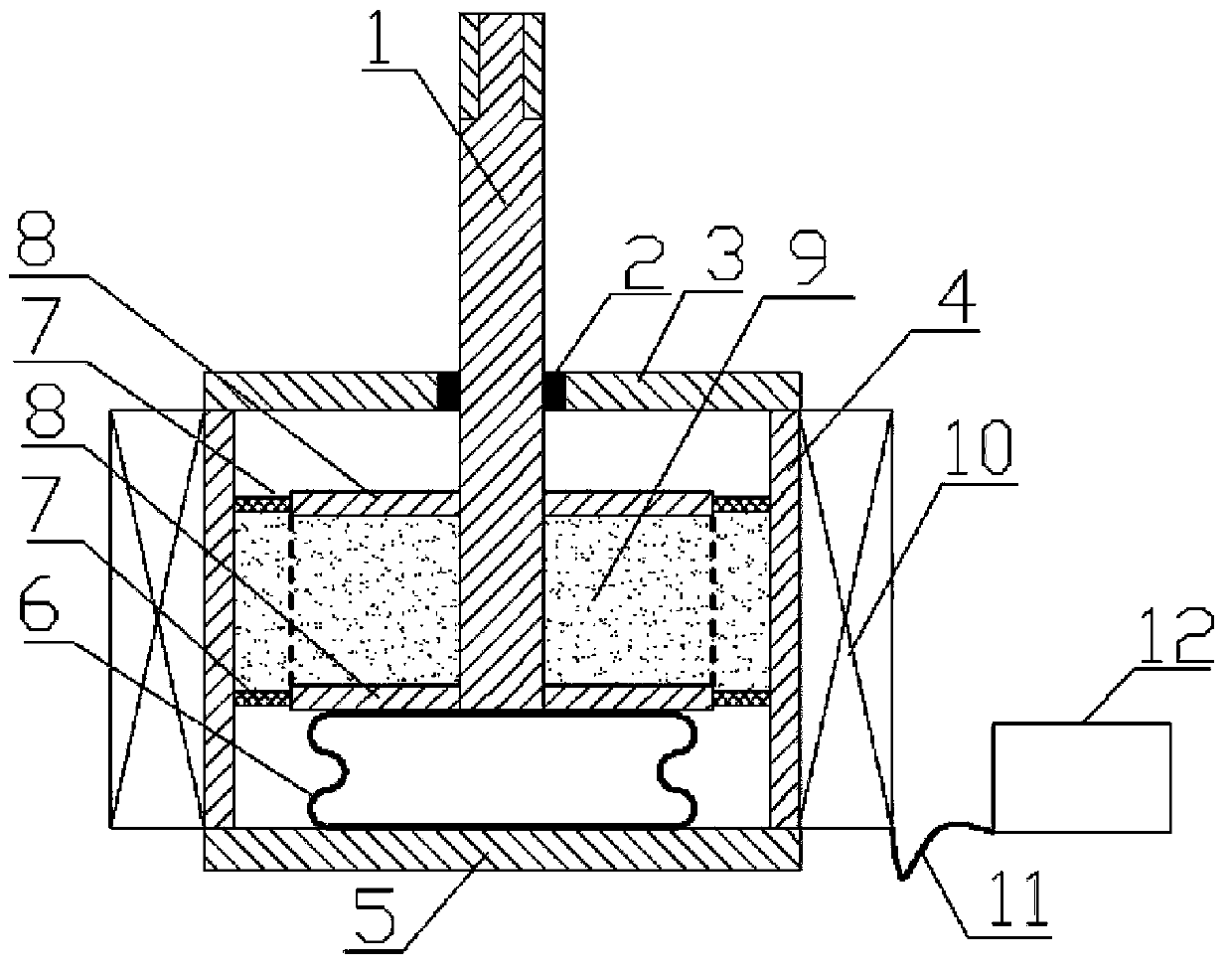

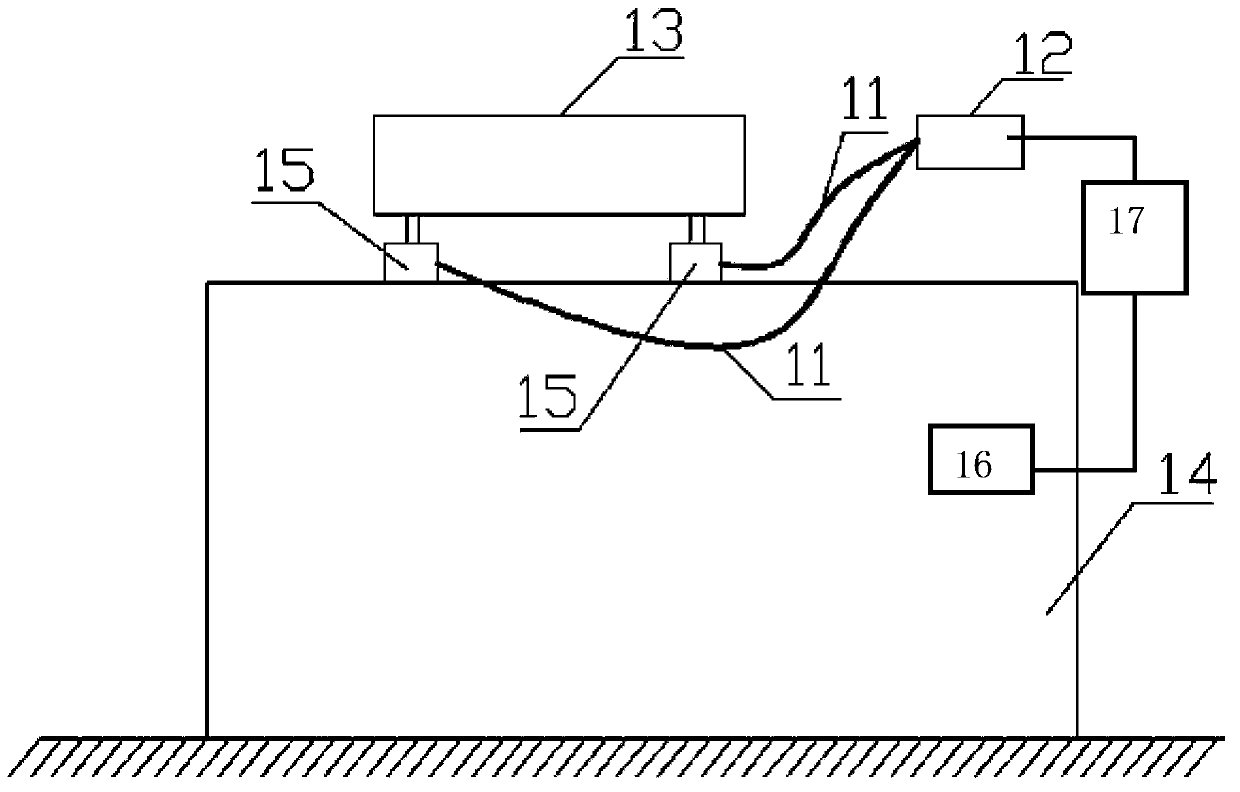

[0024] figure 1 It is a structural schematic diagram of the present invention, figure 2 It is a structural schematic diagram of the damping system of the present invention, as shown in the figure: the film magneto-rheological damper of this embodiment includes a cylinder 4 and a damping assembly located in the cylinder 4, and the damping assembly includes a cylinder 4 located in the cylinder 4 The damping plate 8 arranged side by side along the axial direction of the cylinder body 4 and the damping diaphragm located around the damping plate 8 and sealingly connected between the damping plate and the cylinder body, the damping plate, the damping diaphragm and the cylinder body 4 jointly enclose a Damping chamber, the damping chamber is filled with magnetorheological medium 9; the damping diaphragm is made of flexible or / and elastic material; The damping rod 1 that is fixedly connected to the damping plate in the axial direction, that is to say, the damping rod 1 can be fixedl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com