Refrigerator

A refrigerator and heat exchange technology, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

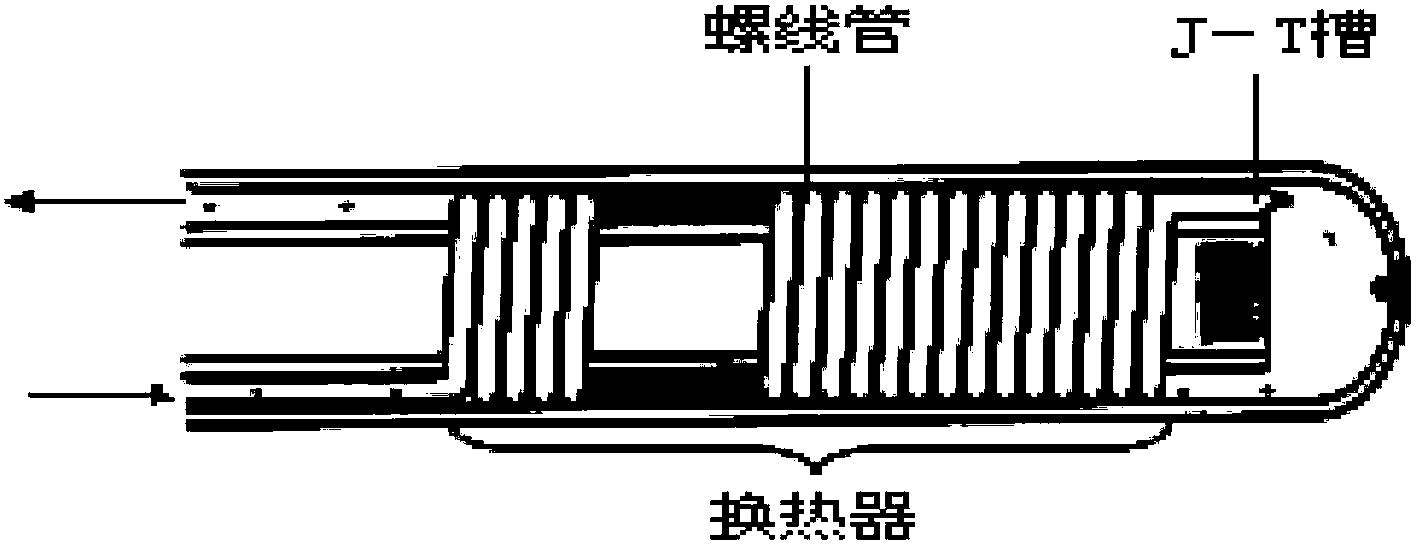

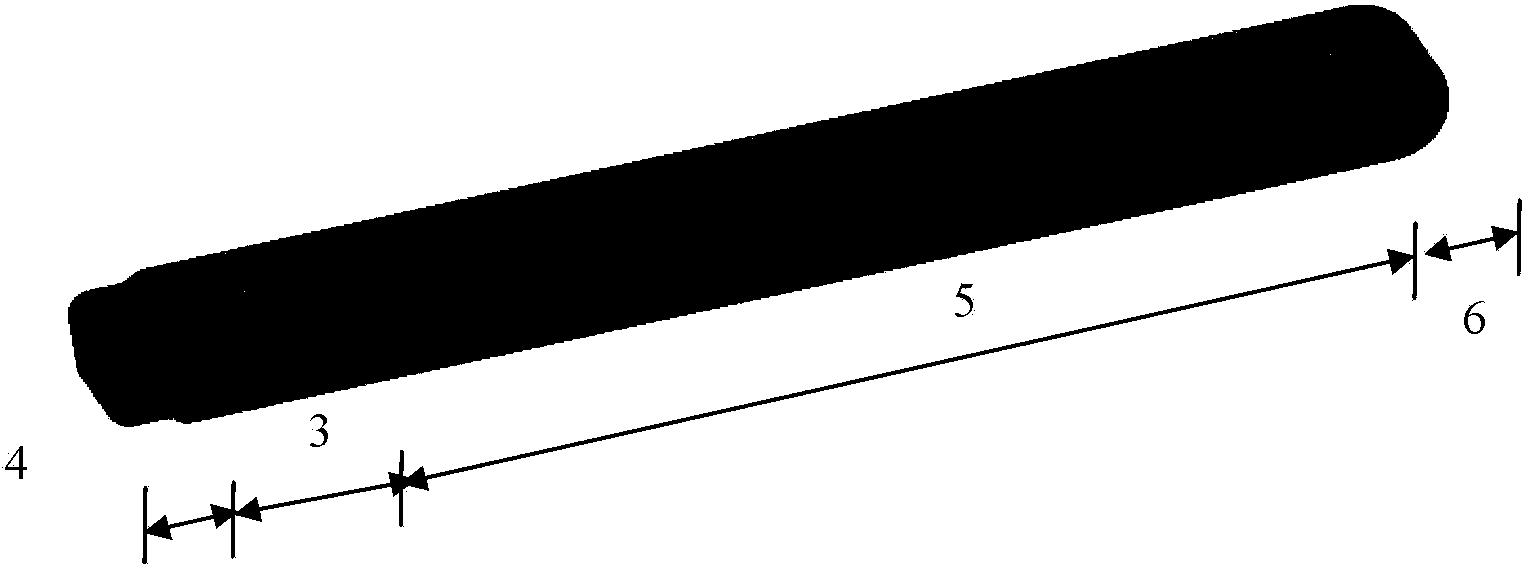

[0050] figure 2 It is a structural schematic diagram of the refrigerator in this embodiment; Figure 5 It is a partial structural schematic diagram of the refrigerator in the embodiment. Such as figure 2 As shown, the refrigerator combines a J-T effect refrigerator with a multi-layer microchannel structure made by atomic diffusion fusion welding technology, including: an inlet and outlet part 6, a heat recovery part 5, a throttling part 3, and an evaporation chamber 4.

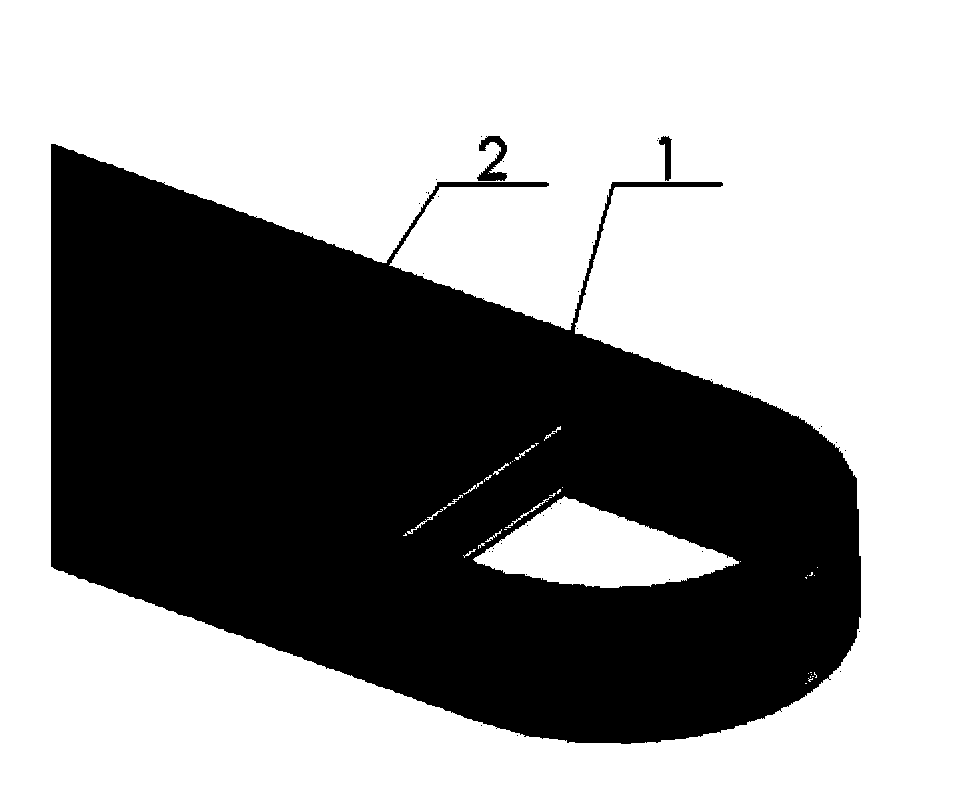

[0051] image 3 It is a partial structural schematic diagram of the inlet and outlet of the refrigerator in the embodiment. Such as image 3 As shown, the inlet and outlet part 6 has an inlet 1 and an outlet 2. The inlet can allow relatively high-temperature and high-pressure gas to enter the refrigerator and distribute the airflow formed by the relatively high-temperature and high-pressure gas to the heat recovery heat exchange part connected thereto. The relatively high-temperature and high-pressure g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com