Multifunctional compression and shear test machine

A testing machine, multi-functional technology, applied in the direction of using stable shear force to test material strength, using stable tension/pressure to test material strength, measuring device, etc. Inaccurate results, troublesome use, etc., to achieve the effect of simple structure, diverse functions, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

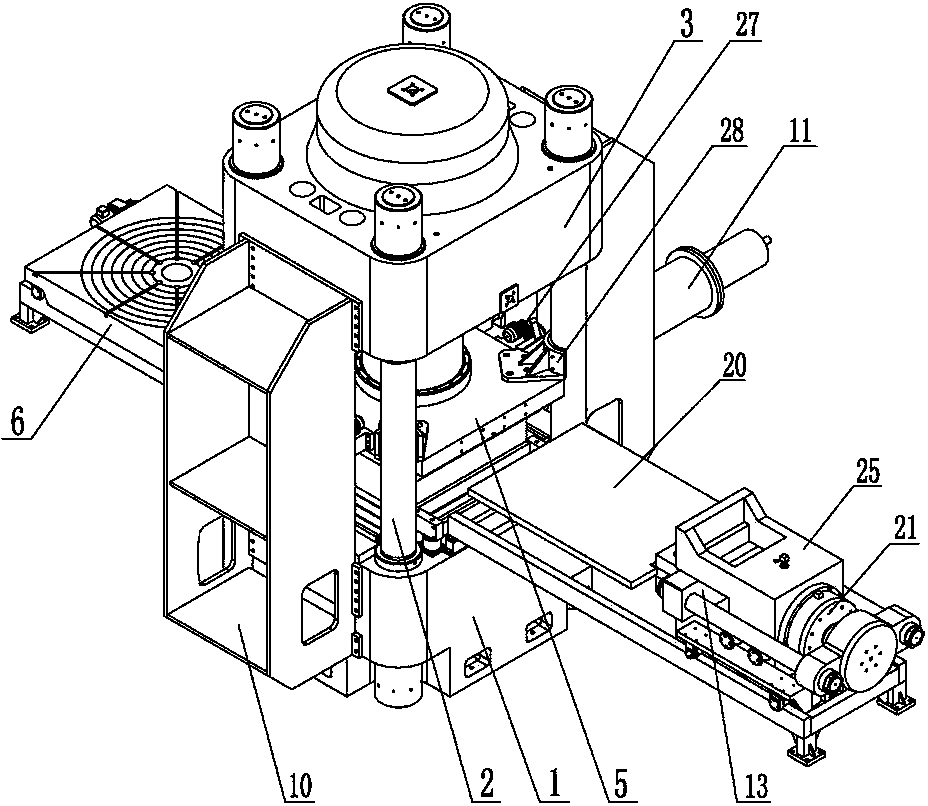

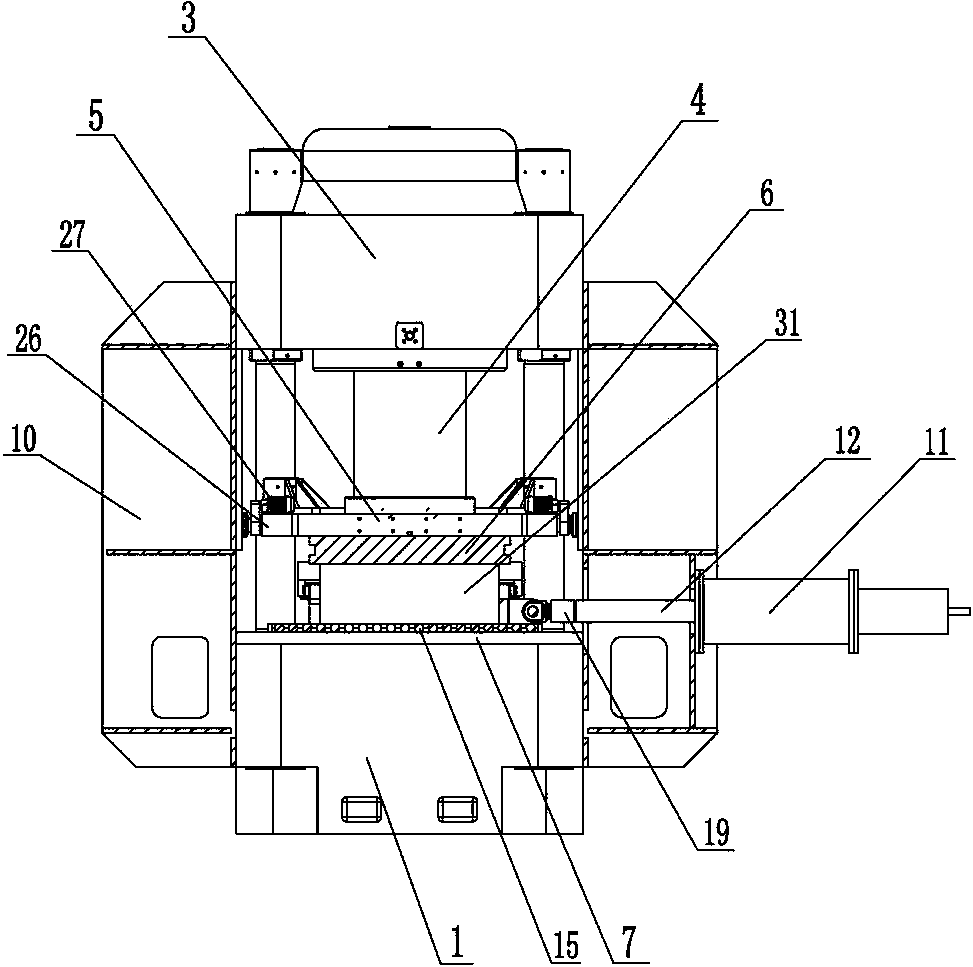

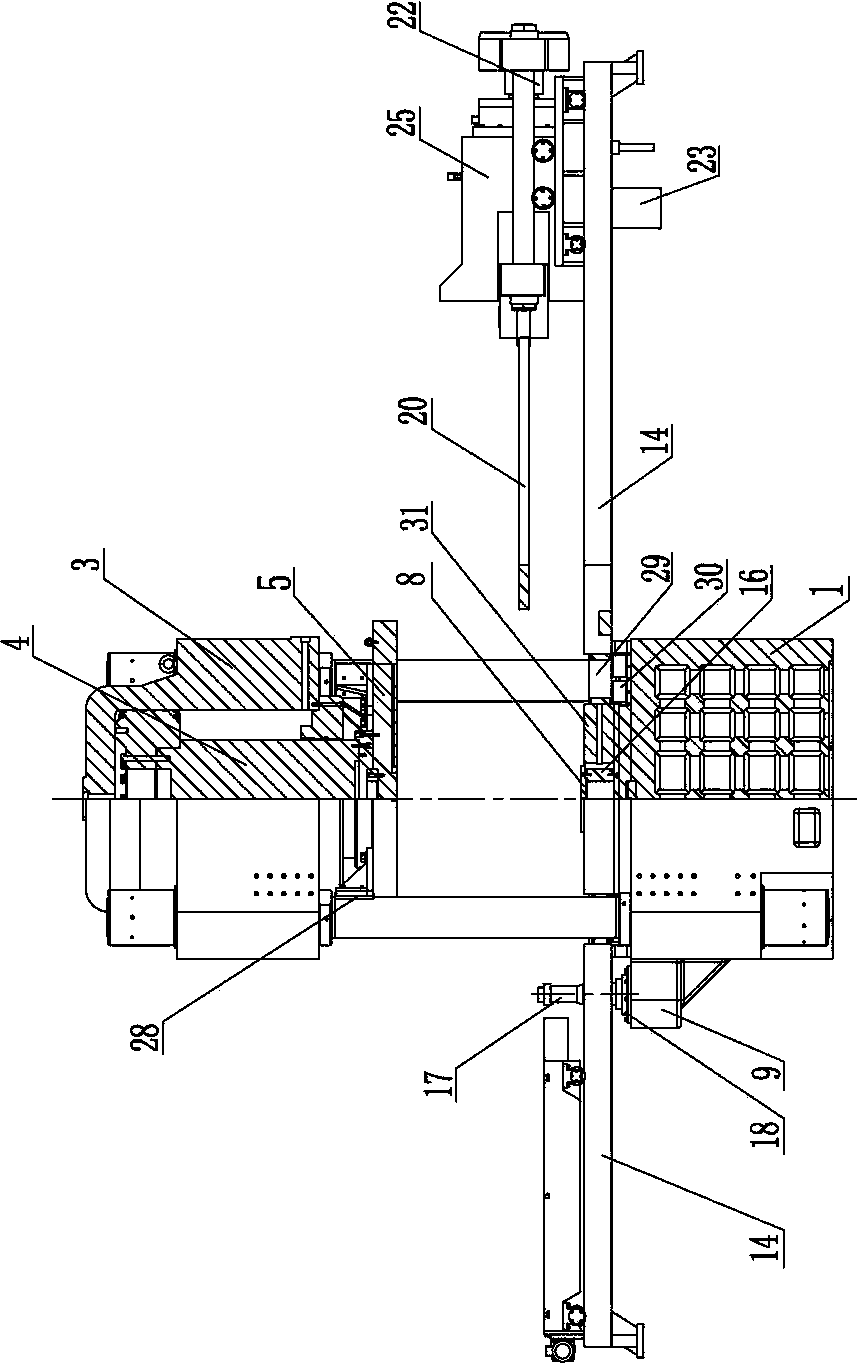

[0023] Please refer to the attached figure 1 to attach image 3 Shown, the present invention is a kind of multifunctional compression-shear testing machine, and it is made up of frame 1, column 2, main oil cylinder 3, main piston rod 4, upper pressing plate 5, dynamic lower pressing plate 6, lower bearing plate 7, backing plate 8 , Corner oil cylinder 9, dynamic support frame 10, dynamic hydraulic oil cylinder 11, dynamic hydraulic piston rod 12 and shear mechanism 13 etc. are composed of several parts.

[0024] Wherein, the column 2 is vertically arranged on the frame 1 . The dynamic support frame 10 is fixed on the front and rear sides of the frame 1 . Guide rails 14 are respectively arranged on the left and right sides of the frame 1, and the dynamic lower pressing plate 6 and the shearing mechanism 13 are respectively arranged on the guide rails 14 and can move along the guide rails 14;

[0025] The main oil cylinder 3 is fixed on the top of the column 2 . The main pis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com