Optical waveguide directional coupler

A technology of directional coupler and optical waveguide, which is applied in the coupling of optical waveguide, light guide, optics, etc., can solve the problems of large coupling effect and coupling distance, low tolerance of directional coupler manufacturing process, etc., to achieve easy manufacturing and improve manufacturing process The effect of high tolerance and process tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

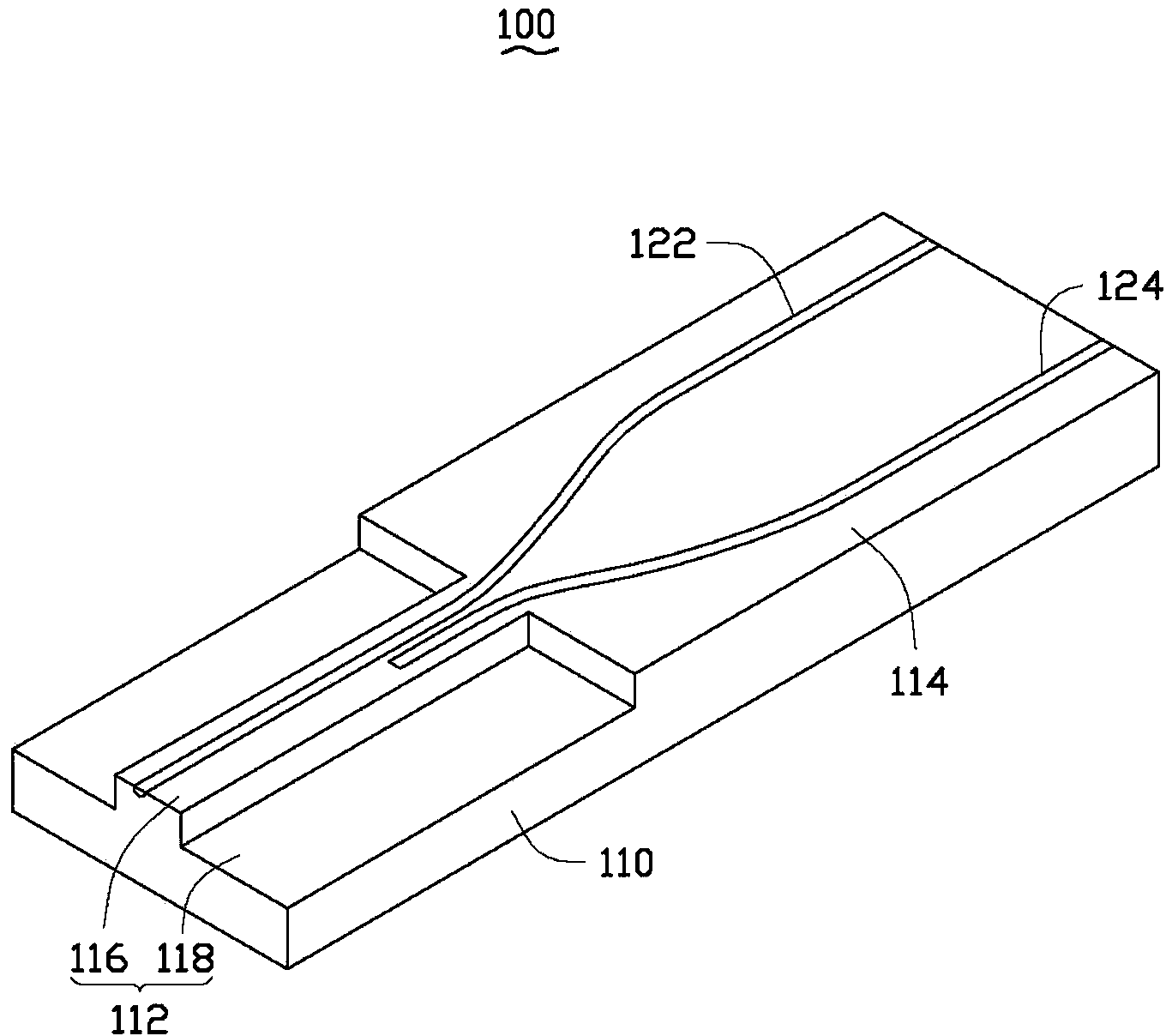

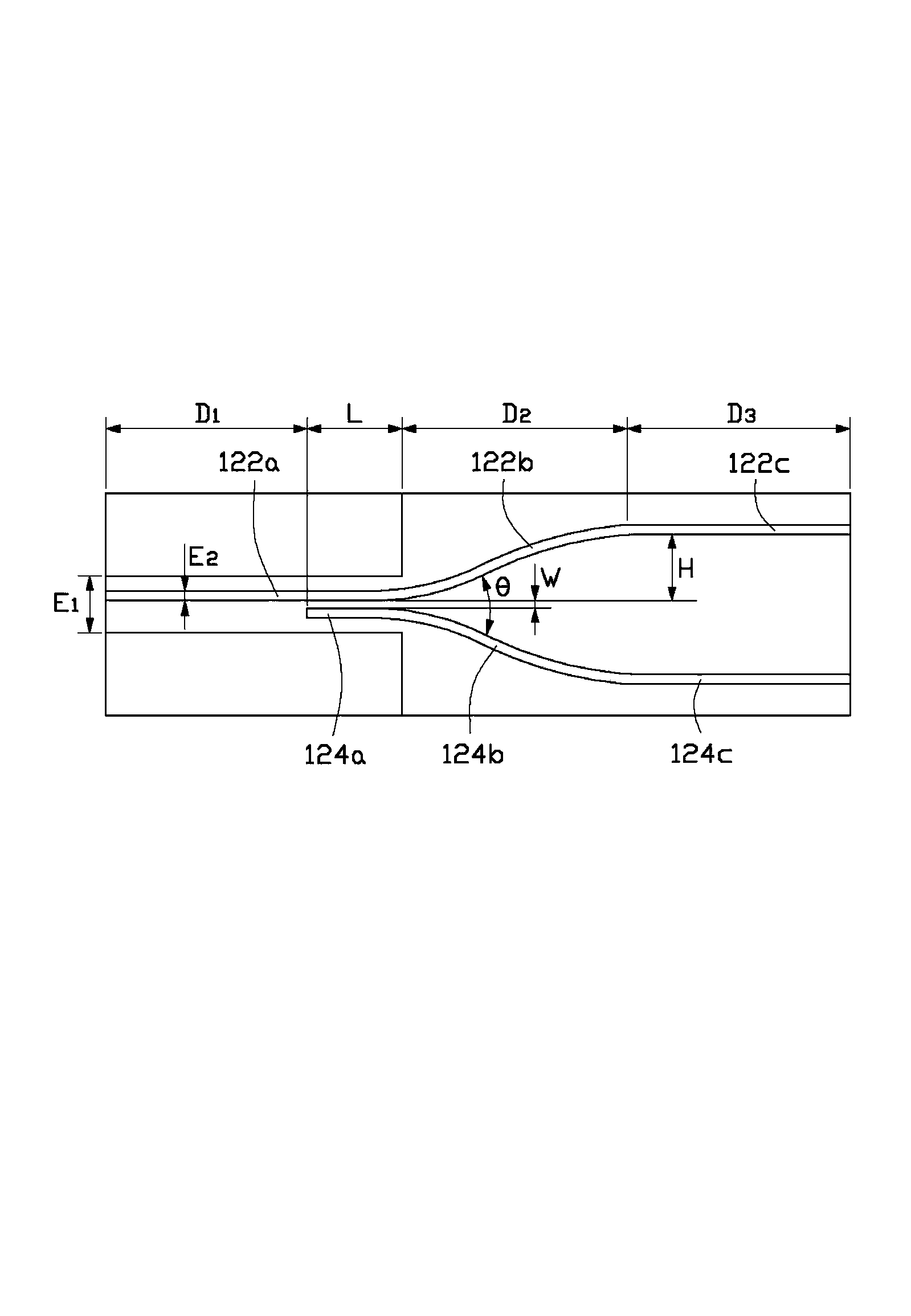

[0012] see figure 1 and figure 2 The optical waveguide directional coupler 100 provided by the embodiment of the present invention includes a substrate 110 and two optical waveguides 122, 124 formed on the substrate 110.

[0013] The base 110 includes a ridge region 112 with a convex cross-section, and a rectangular region 114 adjacent to the ridge region 112 . The raised middle portion of the ridge area 112 forms an inner ridge area 116 , and the upper surface of the inner ridge area 116 is smoothly connected to the upper surface of the rectangular area 114 . The region of the ridge region 112 on both sides of the inner ridge region 116 forms a plate region 118 . Devices such as electrodes (not shown) can be placed on the plate area 118 . The outer edge of the plate area 118 is flush with the outer edge of the rectangular area 114 . In this embodiment, the width E of the inner ridge region 116 1 is 32 μm.

[0014] The two optical waveguides 122 , 124 straddle the inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com