Perpendicular lead cold atom chip manufacturing method

A technology of atomic chips and manufacturing methods, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as difficult to achieve deep silicon etching, affect the potential energy of annular magnetic traps, reduce chip reliability, etc., and achieve improvement The effect of maximum operating current, reduced chip power consumption, binding capacity and increased reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

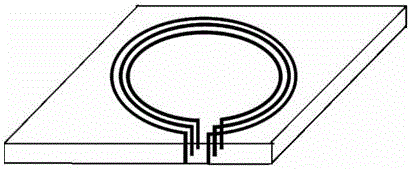

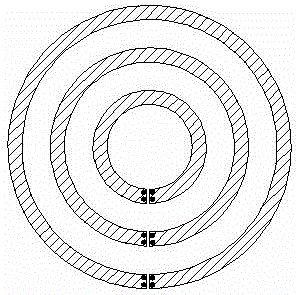

[0035] In order to further explain the technical means and functions adopted by the present invention to achieve the intended purpose of the invention, the specific implementation of the present invention will be described below in conjunction with the atomic chip design.

[0036] The circular magnetic trap of the atomic chip is selected to be designed as the first ring radius R1=500um, the second ring radius R2=600um, the third ring radius R3=700um, the ring line width is 90um, and the gap between adjacent ring lines is 10um (design reference physics Journal article ActaPhys.Sin. Vol.65, No.6 (2016) 060302). According to the design, set the vertical lead center distance to 1 / 3 (line width + loop space) = 34um. Gold wire is selected as the vertical lead, the diameter of the gold wire is 12um, and the corresponding maximum fusing current is greater than 5A. The 12um gold wire is the size of conventional bonding gold wire for integrated circuits, which is feasible.

[0037] An...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com