A device for generating cylindrical vector polarized light beams by a polarizing prism

A technology of polarizing prisms and cylindrical vectors, applied in the field of optics, can solve the problems of low polarization of vector beams, difficulty in obtaining diffractive optical elements, and limitations in practical applications, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

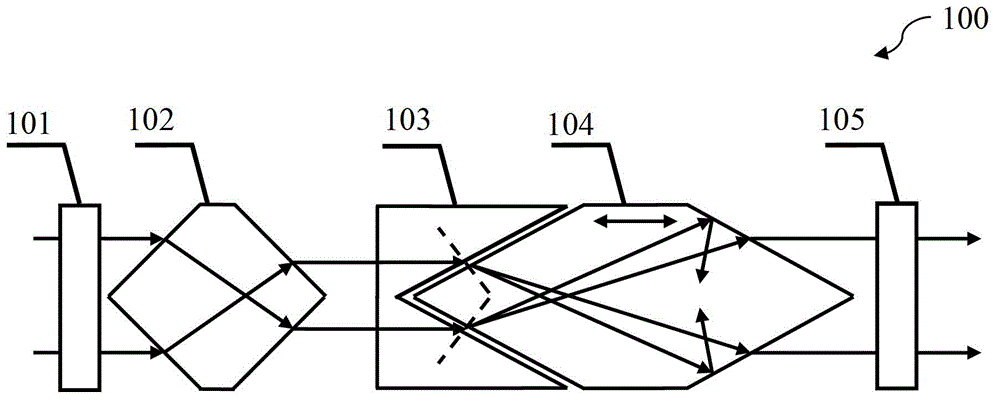

[0027] figure 1 A schematic diagram of a device for generating cylindrical vector polarized light beams for the polarizing prism involved in the present invention.

[0028] The incident light beam sequentially passes through the adjustable beam expander 101 , the common-bottom double-circle mirror transmission mirror 102 , the concave-cone transmission mirror 103 , the birefringent crystal common-bottom double cone 104 and the vortex phase plate 105 . The process of the incident beam passing through the above optical components has the following steps:

[0029] Step S1-01:

[0030]After the incident beam is reshaped by the adjustable beam expander 101, a parallel beam is generated and incident on the common-bottom biconical transmission mirror 102, and the line connecting the two cone vertices of the common-bottom biconical transmission mirror 102 coincides with the symmetry axis of the adjustable beam expander 101 , is the symmetry axis of the system, and the apex of the co...

Embodiment 2

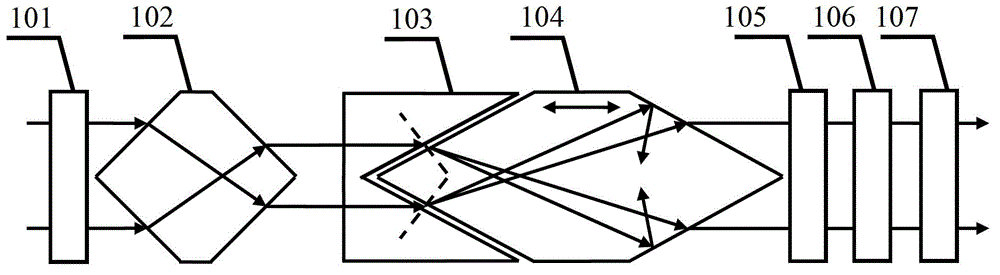

[0051] figure 2 A schematic diagram of generating a rotationally symmetric cylindrical vector beam for the device for generating a cylindrical vector polarized beam by a polarizing prism involved in the present invention.

[0052] Such as figure 2 As shown, another embodiment of the method of the present invention is provided. Based on the above-mentioned cylindrical vector beam generation method, an incident half-wave plate 106 and an outgoing half-wave plate 106 are sequentially arranged on the outgoing beam of the vortex-type phase plate 105. A wave plate 107.

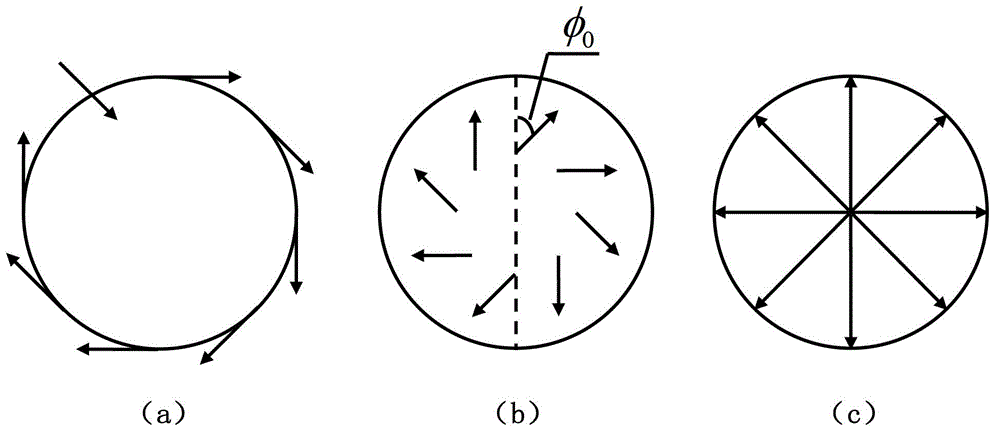

[0053] image 3 Schematic diagram of adjusting the included angle between half of the incident wave plate and half of the outgoing wave plate at the back end of the device for adjusting the polarizing prism to generate cylindrical vector polarized beams to generate rotationally symmetrical cylindrical vector beams.

[0054] Such as image 3 As shown, because the birefringent crystal common-bottom bicone 104 ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com