Input circuit for industrial control with low heat dissipation

An industrial control system and circuit technology, applied in general control systems, program control, computer control, etc., can solve problems such as large voltage drop series resistors and dissipation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

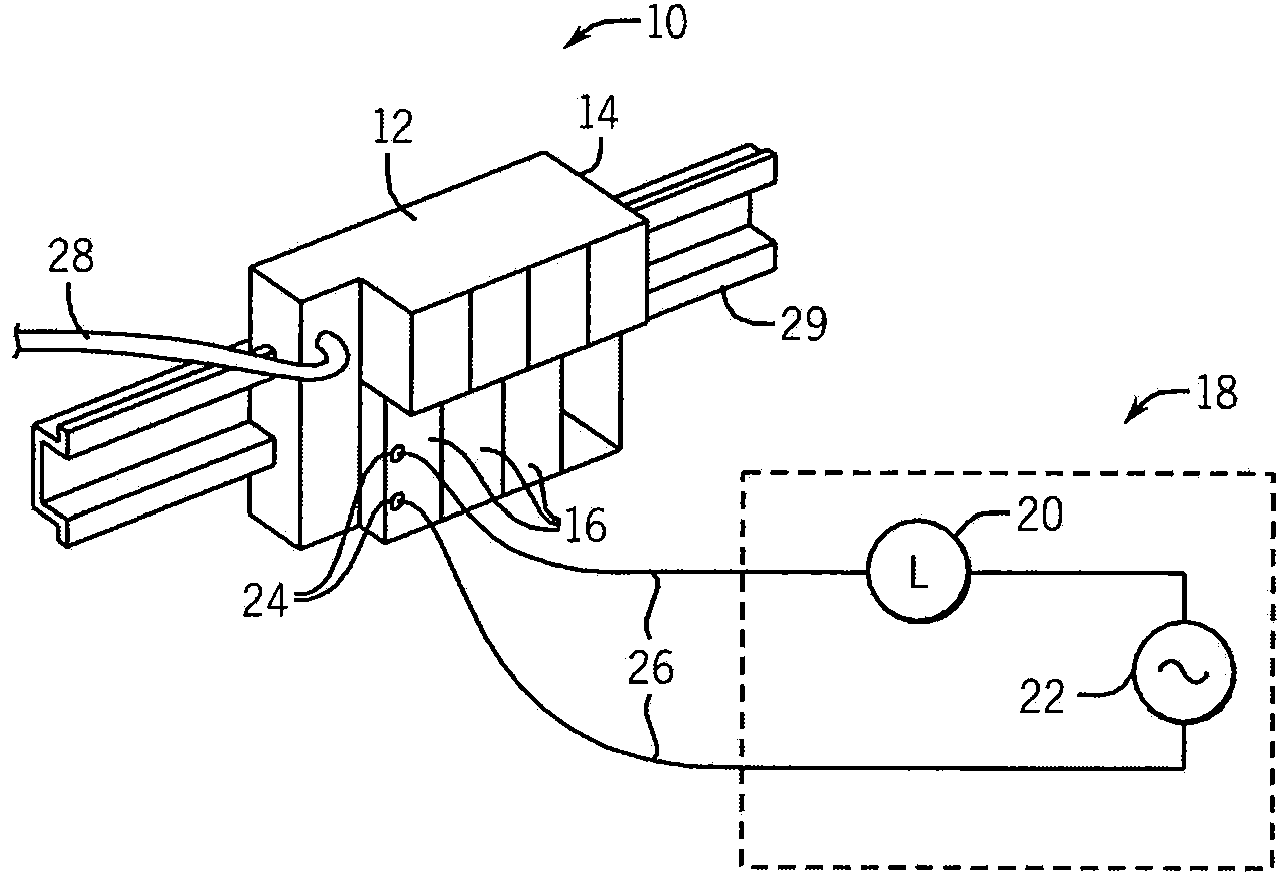

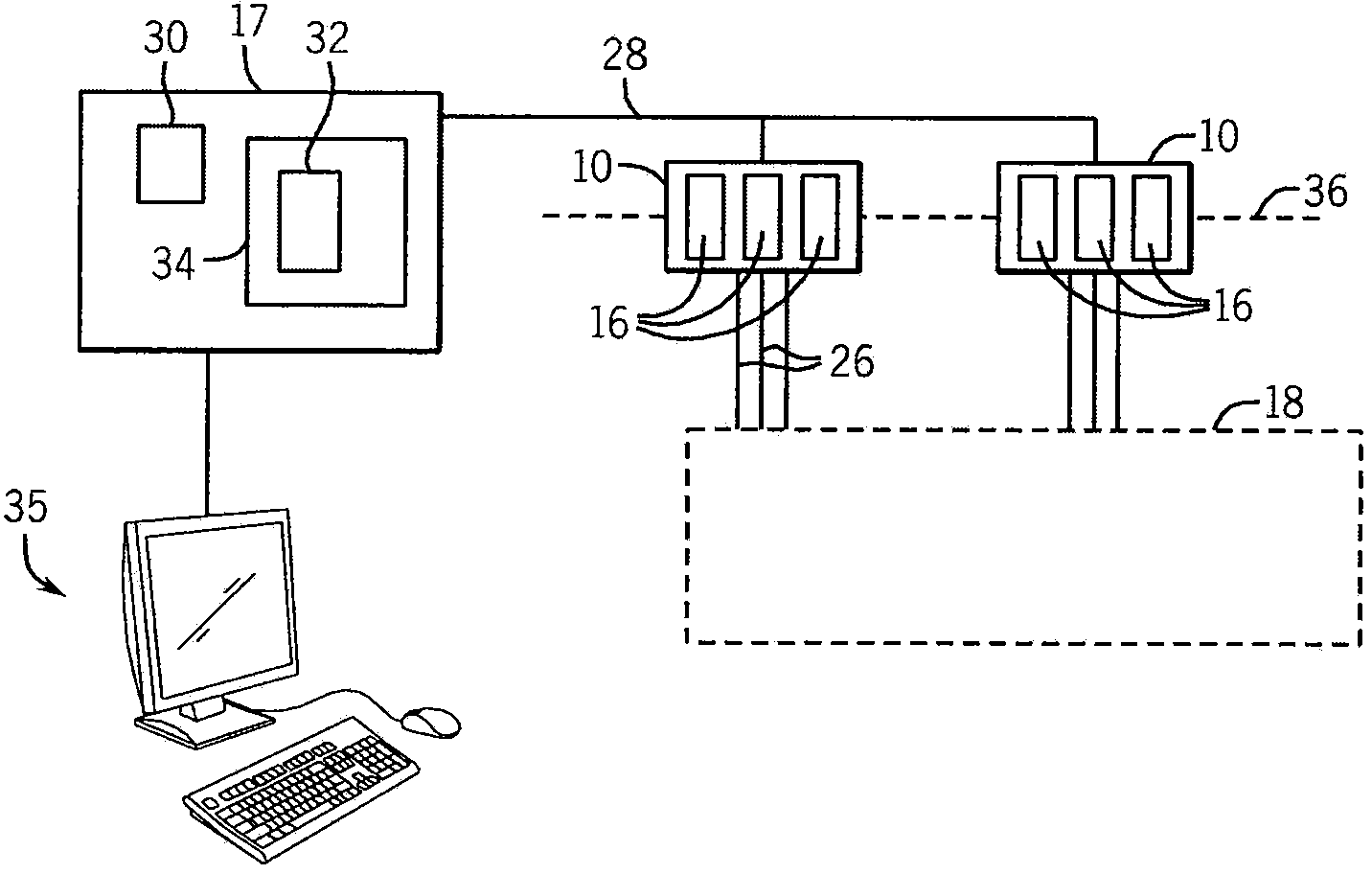

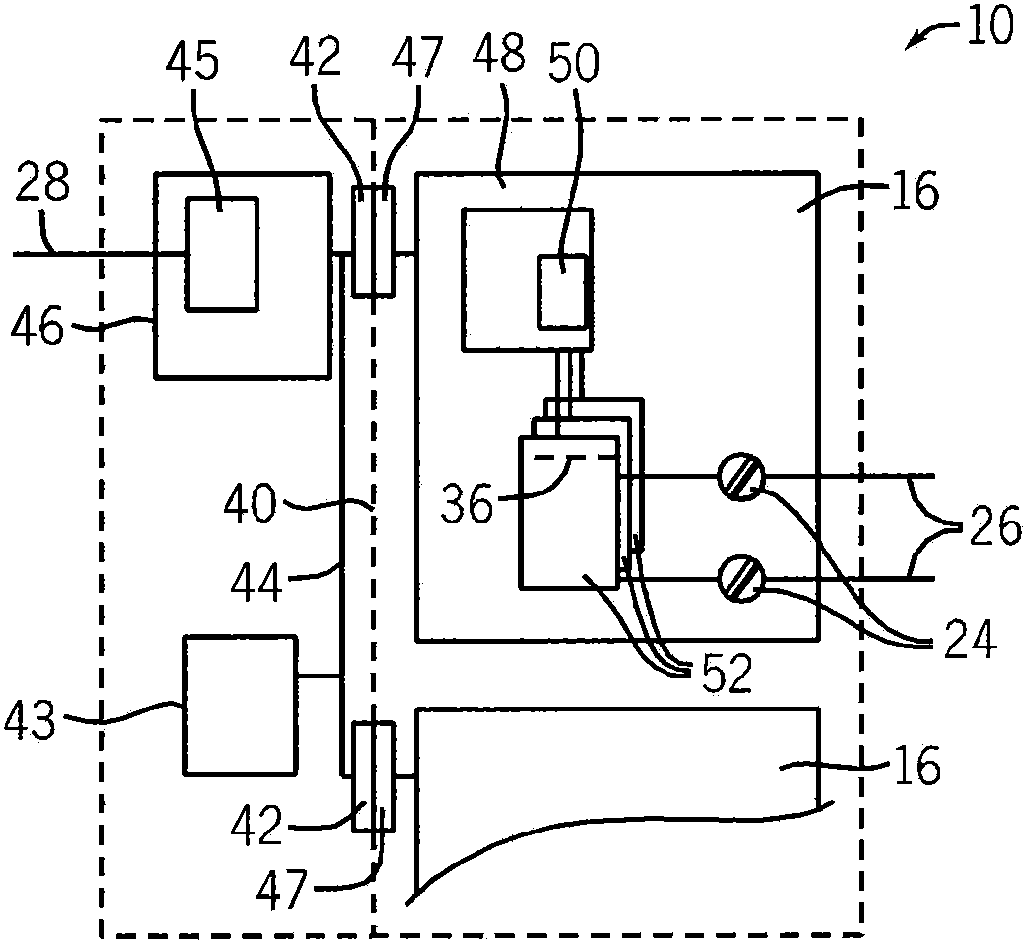

[0024] now refer to figure 1 and 2 , the I / O block 10 may provide a unit housing 12 having a plurality of openings 14 for positioning and supporting a removable or permanently installed I / O module 16 . I / O modules 16 typically provide an electrical interface between an industrial controller 17 and an industrial process or machine 18 having actuators presenting a load 20 powered by an external field-side power supply 22 that can is the DC source or AC source (as shown) to be described. Each of the I / O modules 16 may have exposed screw terminals 24 for connecting the circuitry of the I / O module 16 to a field-side power source 22 of the industrial process or machine 18 via electrical conductors 26 .

[0025] The housing 12 of the I / O block 10 may be supported, for example, on a DIN rail 29 of the type known in the art, or the housing 12 of the I / O block 10 may provide another mounting arrangement that allows it to be located near the desired controlled load 20 . The I / O block...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com