Full-automatic intermediate-bulk-container post-processing device and processing method thereof

A post-processing, fully automatic technology, applied in the processing field of ton barrel post-processing equipment, fully automatic ton barrel post-processing equipment, and fully automatic ton barrel post-processing equipment, can solve the problem of low production efficiency, large subjective influence and waste of manpower and site problems, to achieve the effect of reducing human participation, improving work efficiency, and improving detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

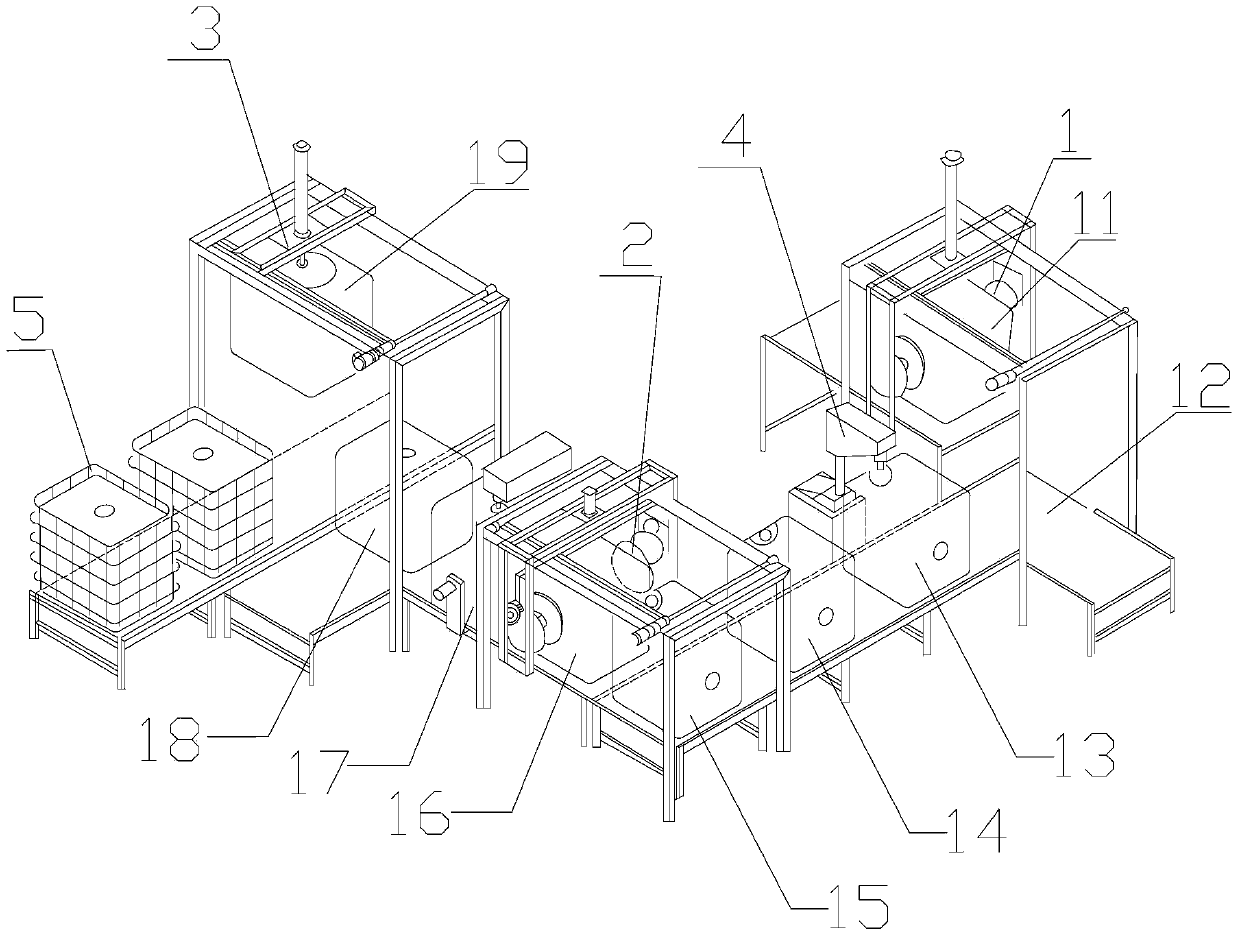

[0042] see figure 1 , the present invention discloses a fully automatic ton barrel post-processing equipment, which includes nine stations, respectively the first station to the ninth station.

[0043] The first station 11 is equipped with a first manipulator 1 and a first lifting and turning system. The first manipulator 1 cooperates with the first lifting and turning system to lift and turn the tonnage and place it in the second station 12 .

[0044] The second station 12 is equipped with a weighing system and a first conveying system. The weighing system is used to weigh the tonneau, and the conveying system will transfer the barrel to the third station 13 if it is judged to be qualified.

[0045] The third station 13 is equipped with a first positioning system, a hot plate or ultrasonic welding system 4, and a second transmission system. The first positioning system is used to accurately position the tonnage, and the hot plate or ultrasonic welding system has 4 pairs of to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com