Relay pushing mechanism

A technology of pushing mechanism and relay, applied in relays, electromagnetic relays, detailed information of electromagnetic relays, etc., can solve the problems of weakening the driving force and holding force of the moving iron core, difficult to guarantee the size, and difficult to process, so as to reduce the processing cost and Material cost, improved driving force and holding force, effect of simplified machining process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

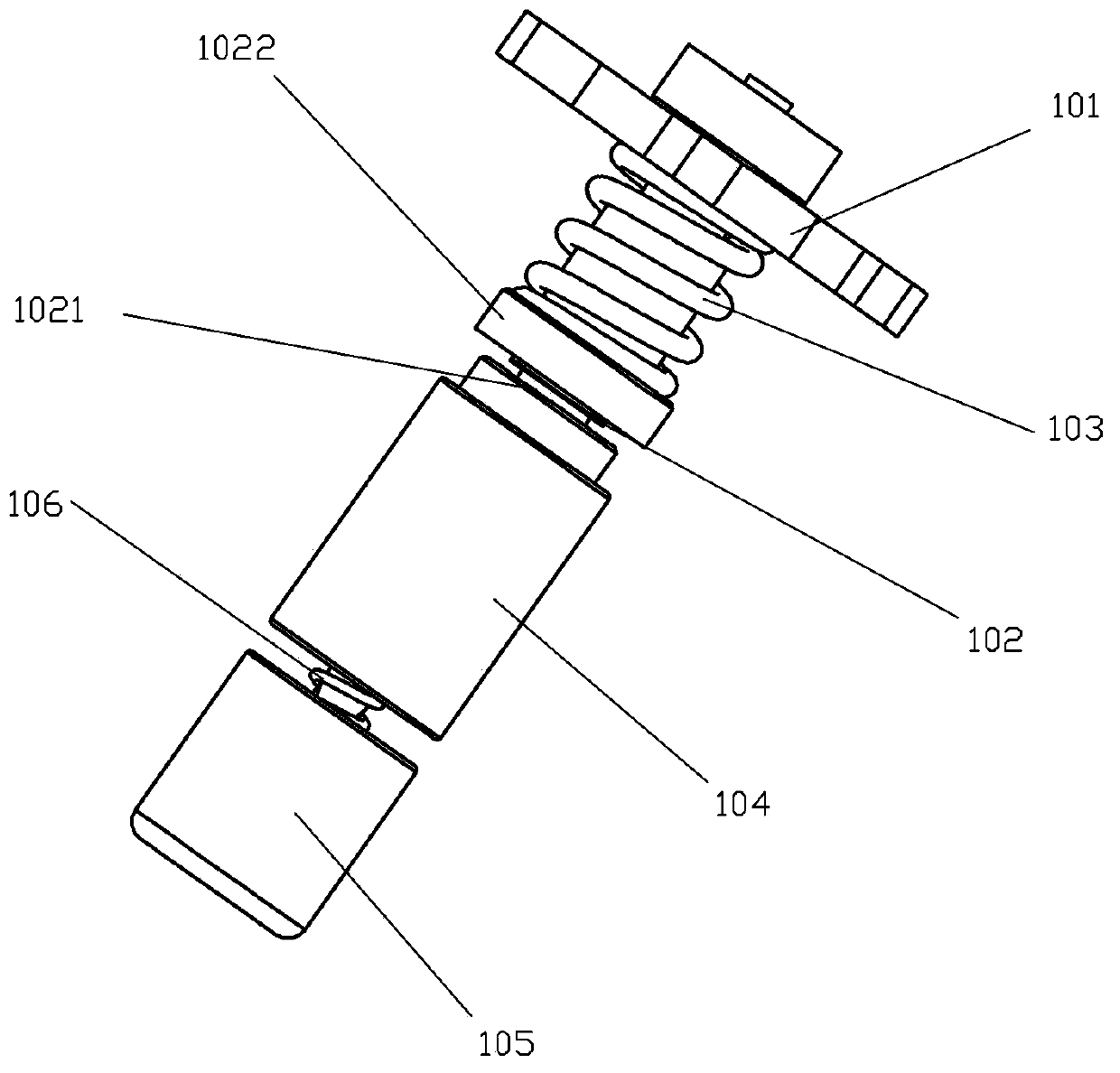

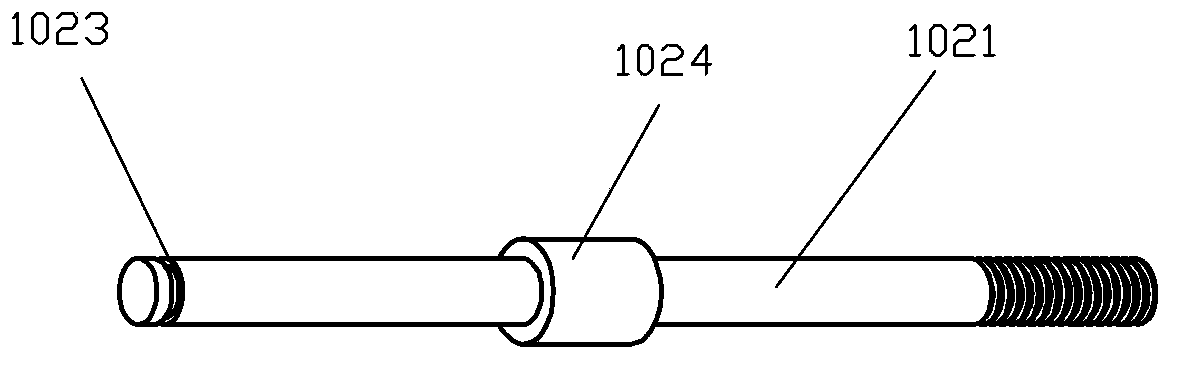

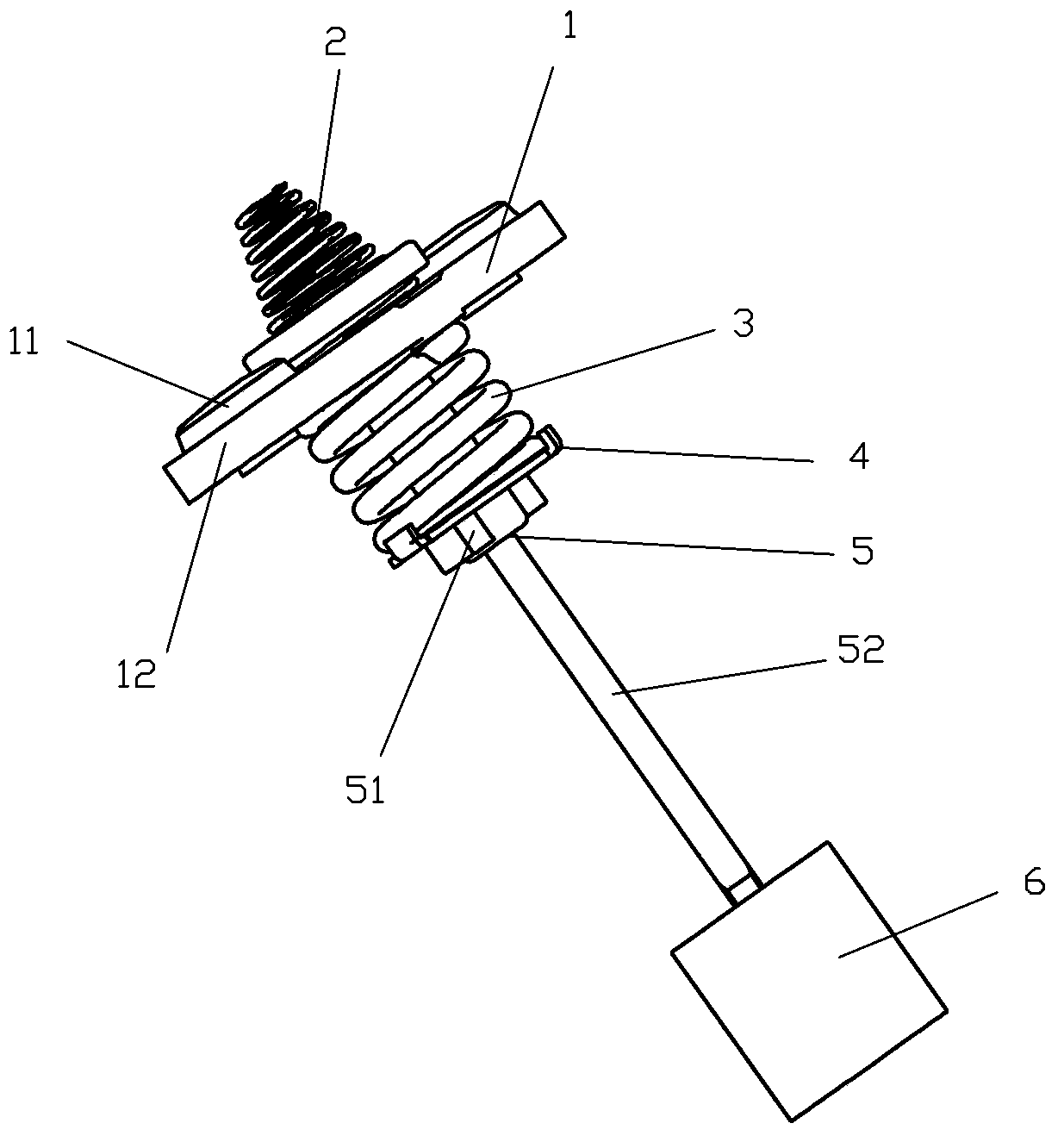

[0041] Examples, see Figure 3 to Figure 13As shown, a pushing mechanism of a relay of the present invention includes a moving spring part 1, a return spring 2, a main spring 3, a fixed plate 4, a pushing rod part 5 and a moving iron core 6; the pushing rod part 5 includes an insulating sleeve 51 and push rod 52; the upper end of the push rod 52 is affixed to the insulating sleeve 51, and the lower end of the push rod 52 is affixed to the moving iron core 6; the moving spring part 1 and the main spring 3 are successively The lower direction of the insulating sleeve 51 is inserted into the insulating sleeve and the upper end of the moving spring part 1 is pressed against the upper edge 511 of the insulating sleeve. Between the lower end of the moving spring part 1 and the fixed plate 4 ; the lower end of the return force spring 2 is against the top end of the insulating sleeve 51 .

[0042] The return force spring 2 is a conical compression spring, and a groove 512 is arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com