Transient voltage suppressor and manufacture method thereof

A technology for transient voltage suppression and manufacturing methods, applied in the manufacture of transient voltage suppressors, and in the field of transient voltage suppressors, can solve the problems of low impurity concentration, low breakdown voltage, and difficulty in realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

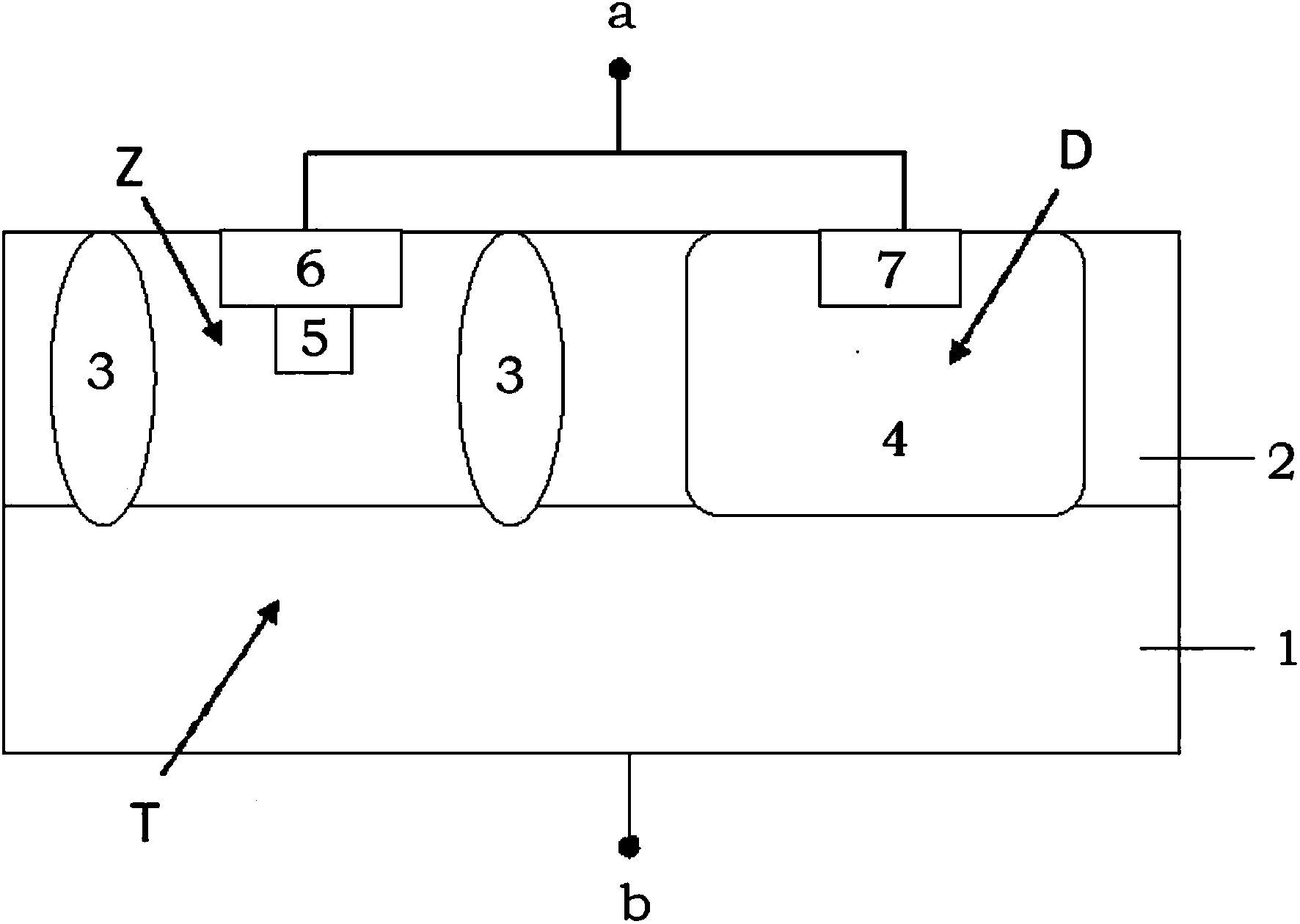

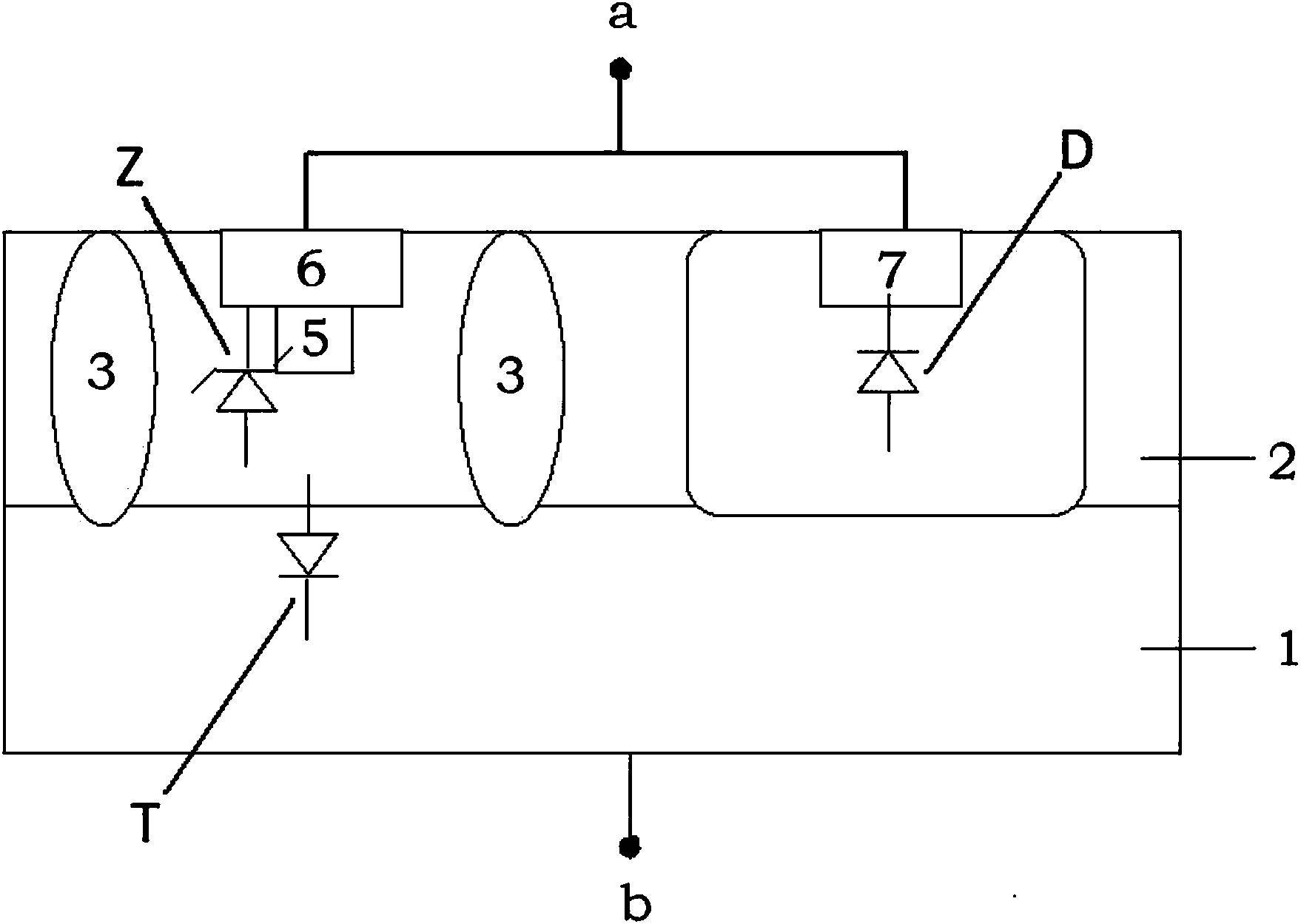

[0046] like figure 1 As shown, the transient voltage suppressor of the present invention includes: a P-type epitaxial layer 2 with a thickness of 6um to 12um on a low-resistance N-type substrate 1, and a P-type isolation well 3 and a P-type epitaxial layer 2 are formed in parallel in the P-type epitaxial layer 2. The deep P well 4, the P type isolation well 3 and the deep P well 4 are in contact with the N type substrate 1, and the P type implantation region 5 in the P type epitaxial layer 2 is formed between the two P type isolation wells 3, and the P type The isolation well 3, the deep P well 4 and the P-type implant region 5 have boron impurities, and the N-type implant region 6 formed above the P-type implant region 5, and the N-type implant region 7 formed in the deep P well 4; The N-type implant region 6 above the implant region 5 and the N-type implant region 7 in the deep P well 4 are connected to one end a of the suppressor, and the N-type substrate is connected to th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com