Apple peeling method

An apple and apple meat technology, applied in the fields of vegetable or fruit peeling, food science, application, etc., can solve the problems of inability to peel by hand, unable to reach processed food, large loss of peeling, etc., to achieve good appearance and affinity. Enhanced, less browning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Apple peeling method includes the following steps:

[0016] (1) Freezing: freeze the apples to be peeled at -20°C for 15 days;

[0017] (2) Defrosting: Immerse the frozen apples in step (1) in cold water and thaw them until the ice coat formed on the surface of the apples is completely melted. At this time, take out the apples and drain the water;

[0018] (3) Peeling: Put the apple described in step (2) into an lye peeling agent, and perform peeling treatment at a temperature of 60°C for 6 minutes;

[0019] (4) Washing: Wash the peeled apple meat in step (3) with clean water twice to obtain the product.

[0020] Wherein, the lye peeling agent includes the following components, and the mass percentage of each component is: sodium hydroxide 3%; sodium chloride 0.4%, sodium carbonate 0.05% and the balance water.

Embodiment 2

[0022] Apple peeling method includes the following steps:

[0023] (1) Freezing: freeze the peeled apples at -15°C for 20 days;

[0024] (2) Defrosting: Immerse the frozen apples in step (1) in cold water and thaw them until the ice coat formed on the surface of the apples is completely melted. At this time, take out the apples and drain the water;

[0025] (3) Peeling: Put the apple described in step (2) into an lye peeling agent, and perform peeling treatment at a temperature of 70°C for 5 minutes;

[0026] (4) Washing: Wash the peeled apple meat in step (3) with water for 3 times to obtain the product.

[0027] Wherein, the lye peeling agent includes the following components, and the mass percentage of each component is: potassium hydroxide 5%; sodium chloride 0.2%, sodium carbonate 0.05% and the balance water.

Embodiment 3

[0029] Apple peeling method includes the following steps:

[0030] (1) Freezing: freeze the apples to be peeled at -18°C for 18 days;

[0031] (2) Defrosting: Immerse the frozen apples in step (1) in cold water and thaw them until the ice coat formed on the surface of the apples is completely melted. At this time, take out the apples and drain the water;

[0032] (3) Peeling: Put the apple described in step (2) into an lye peeling agent, and perform peeling treatment at a temperature of 65°C for 6 minutes;

[0033] (4) Washing: Wash the peeled apple meat in step (3) with clean water for 3 times to obtain the product.

[0034] Wherein, the lye peeling agent includes the following components, and the mass percentage of each component is: potassium hydroxide 4%; sodium chloride 0.3%, sodium carbonate 0.07% and the balance water.

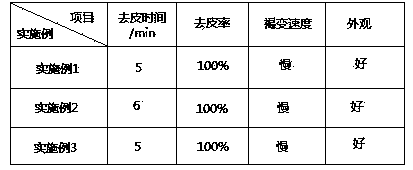

[0035] Using the peeling method described in Examples 1-3 to peel apples, the results are shown in Table 1:

[0036] Table 1: Application results of peeling agents...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com