Sintering desulfurization and white smoke removal system and technological process of sintering desulfurization and white smoke removal system

A technological process and white smoke technology, which is applied to the separation of dispersed particles, chemical instruments and methods, and separation methods, can solve the problems of wasting heat and energy resources, no waste heat recovery, and no heat recovery, etc., so as to improve energy utilization and reduce Energy consumption, the effect of reducing smelting energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

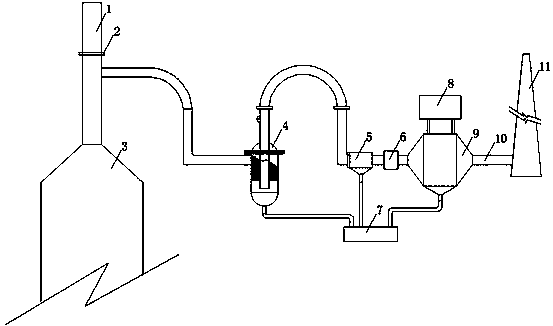

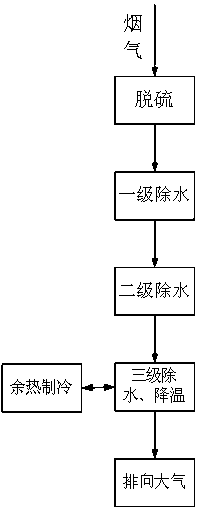

[0035] Such as figure 1 , 2 As shown, this embodiment provides a sintering desulfurization and white smoke removal system. The top of the desulfurization tower 3 is provided with a smoke exhaust chimney 1. Further, the smoke exhaust chimney is connected with a dehumidification system, and the flue gas can enter the dehumidification system for cooling. Dehumidification treatment; at the same time, a flap valve 2 is installed on the exhaust chimney. The flap valve 2 is located above the connection between the exhaust chimney and the dehumidification system. By adjusting the flap valve, the dehumidification system and desulfurization system can be realized. If there is a failure in the dehumidification system, reversely adjust the flap valve so that the flue gas from the desulfurization tower will be discharged to the atmosphere through the exhaust chimney without affecting the desulfurization and emission of the sintering flue gas. After the dehumidification system returns to n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com