Method for producing coated film

A manufacturing method and coating technology, which is applied in the field of film manufacturing, can solve problems such as interlayer mixing, and achieve the effects of preventing interlayer mixing, preventing interference fringes, and preventing whitening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach ]

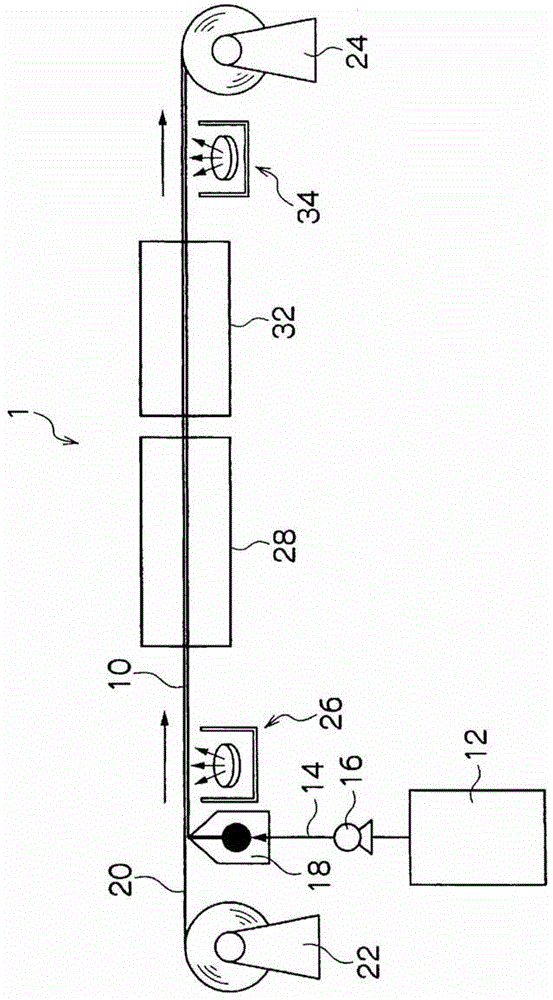

[0048] figure 1 The overall structure of the production apparatus 1 to which the method for producing a film with a coating film of the present invention is applied when a coating film 10 (such as a hard coat layer) is applied in a single layer on a flexible belt-shaped support body 20 (such as a resin film) picture.

[0049] However, in the embodiment of the present invention, an example in which an active ray-curable resin having a molecular weight of 2500 or more is used as the active ray-curable component in addition to the active ray-curable monomer will be described.

[0050] (Coating liquid preparation process)

[0051] exist figure 1 In the coating liquid preparation apparatus 12 shown, the coating liquid containing the active-ray-curable resin with a molecular weight of 2500 or more in a solvent other than an active-ray-curable monomer is prepared as an active-ray-curable component. At this time, the composition of the coating solution is prepared so that the coati...

no. 2 Embodiment approach ]

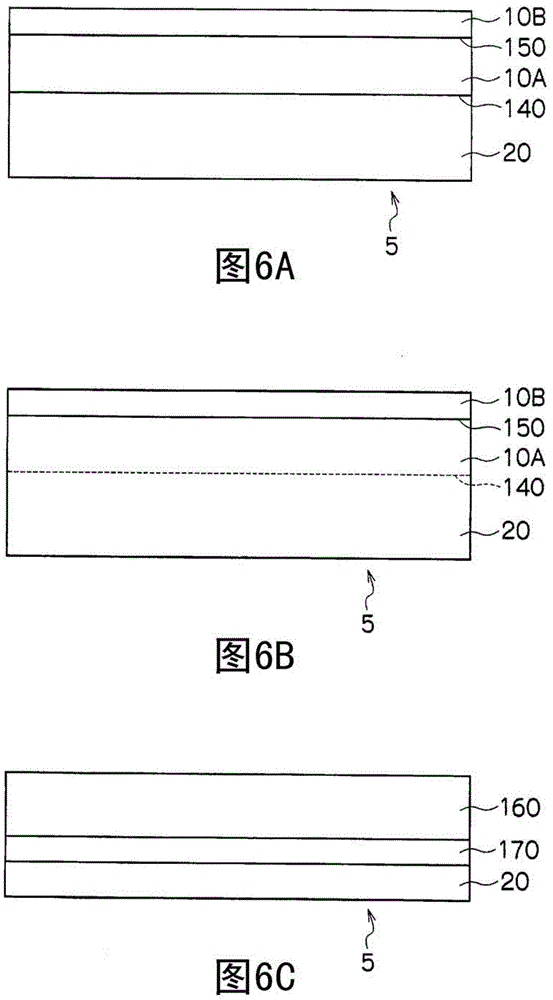

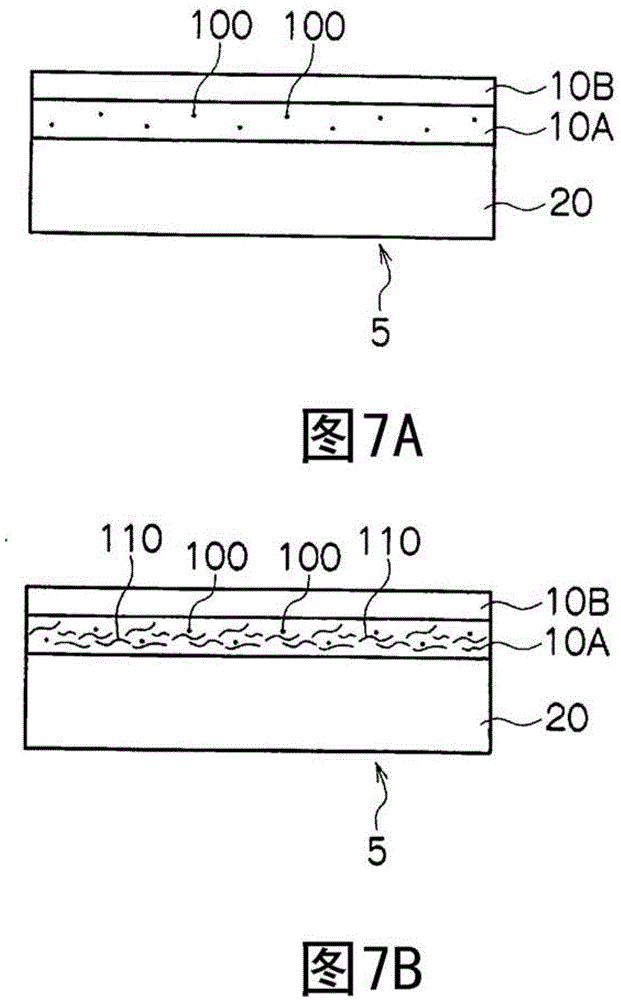

[0106] Figure 5 This is a case where the method for producing a film with a coating film of the present invention is applied to a case where two coating liquids are simultaneously coated in multiple layers on a tape-shaped support to form a two-layer coating film of upper and lower layers. right with figure 1 The same components or devices are marked with the same symbols for description. In addition, an example in which the lower layer of the two layers contains an active ray-curable monomer and an active ray-curable resin with a molecular weight of 2,500 or more as curing components will be described, but it may be contained in the upper layer, or may be contained in both the upper layer and the lower layer. middle.

[0107] (Coating liquid preparation process)

[0108] Such as Figure 5 As shown, in the first coating liquid preparation device 12A, a coating liquid for an under layer containing an active radiation curable resin having a molecular weight of 2500 or more ...

Embodiment 2

[0161] ·Example 2: curing rate 50%, average evaporation rate 2.45g / m 2 Seconds, satisfying the present invention.

[0162] ·Example 3: curing rate 50%, average evaporation rate 3.00g / m 2 Seconds, satisfying the present invention.

[0163] ·Example 4: curing rate 10%, average evaporation rate 2.45g / m 2 Seconds, satisfying the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com