Screw type disassembling tool

A screw type and tool technology, which is applied in the direction of hand-held tools and manufacturing tools, can solve the problems of personal safety, heavy weight, easy to be bruised, and heavy tools, etc., and achieve the effect of simple structure and efficient saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

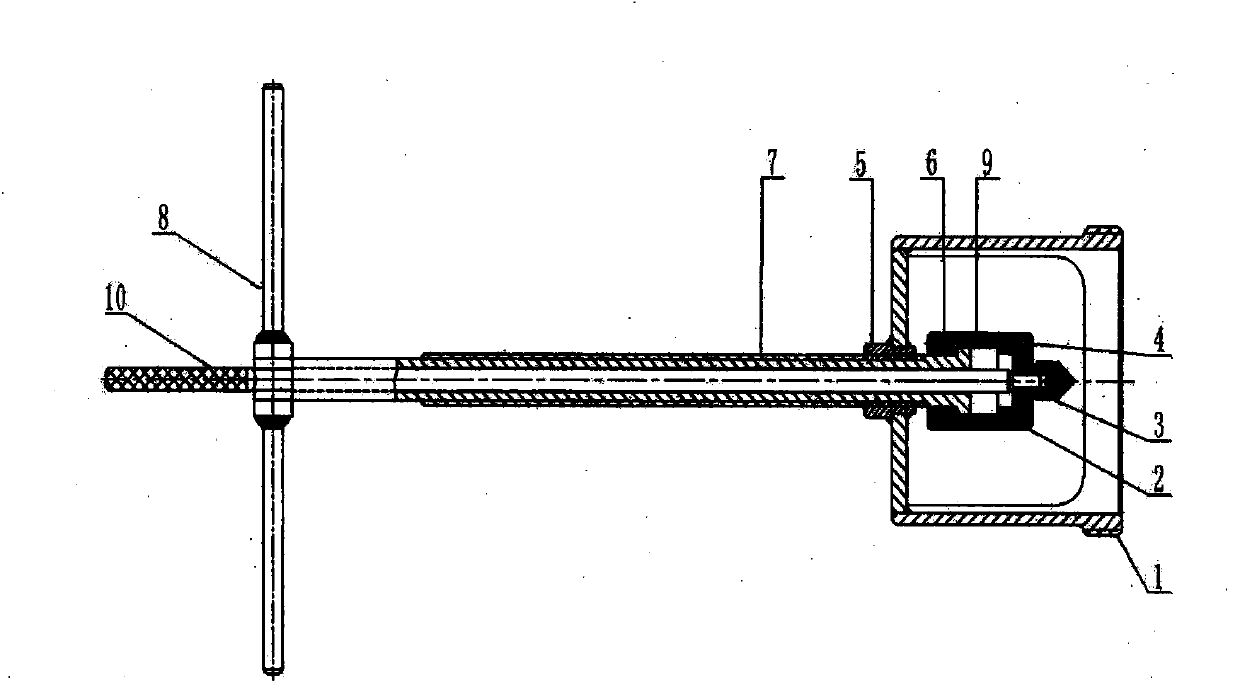

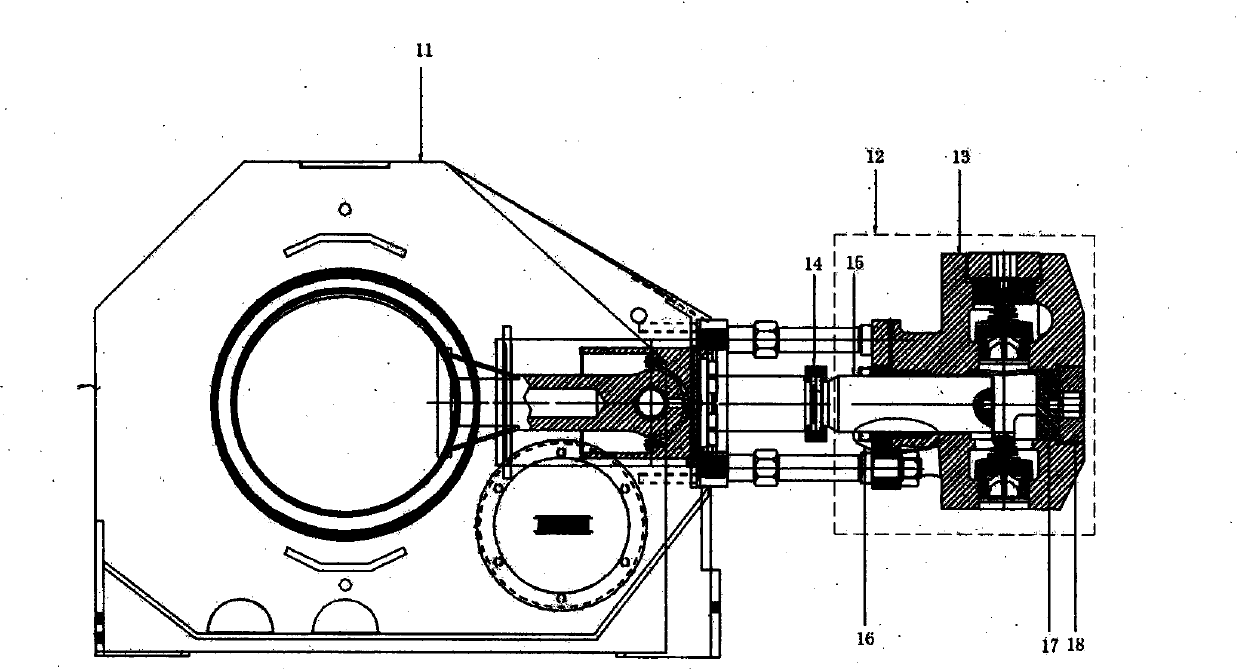

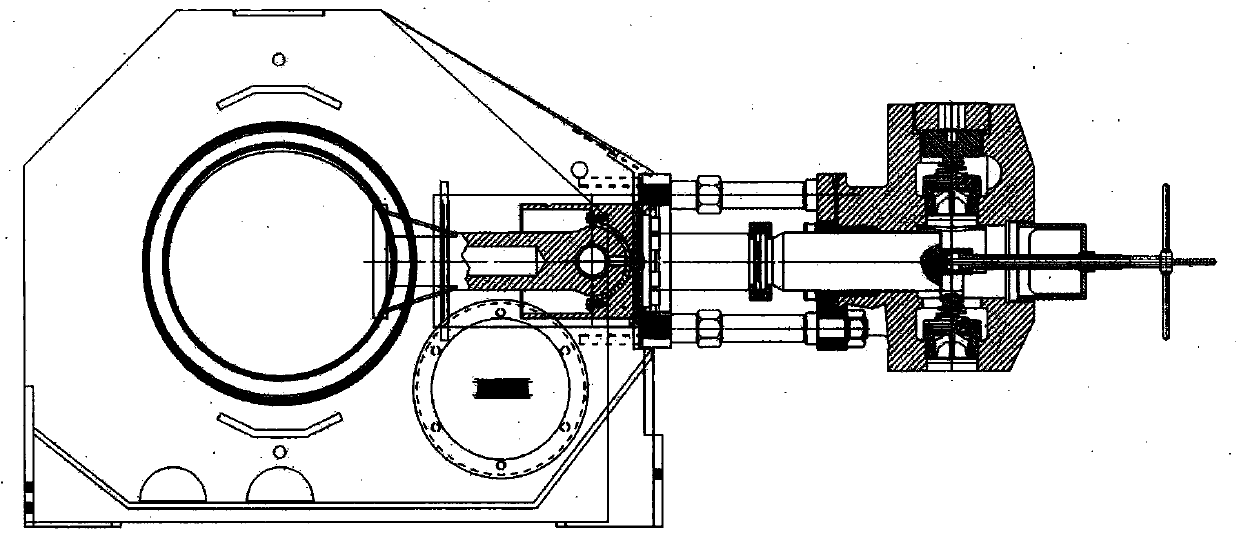

[0021] Such as figure 1 As shown, it is a schematic diagram of the assembly structure of the screw-type dismounting tool of the present invention. The screw-type dismounting tool is supported by a main body with a pressure cap 1, a looper 2, a pull nail 3, a countersunk screw 4, a fixing nut 5, and an end face Bearing 6, tappet screw rod 7, adjustment handle 8, support sleeve 9, adjustment rod 10 form. One end of the main body support pressure cap 1 is provided with an external thread that can be connected with the internal thread of the valve box pressure cap hole in the hydraulic end assembly of the plunger pump, and the other end of the main body support pressure cap 1 is welded with a fixing nut 5 to form a support frame structure , the fixed nut 5 is threadedly connected to the tappet screw rod 7, the main support cap 1 is provided with a looper 2, the looper 2 is provided with a support sleeve 9 and two sets of end bearings 6 respectively located at both ends of the supp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com