High-accuracy position control method for serial robot

A control method and robot technology, applied in the direction of program control of manipulators, manipulators, manufacturing tools, etc., can solve the problems of fragile servo motors, large control energy, large torque and speed jumps, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

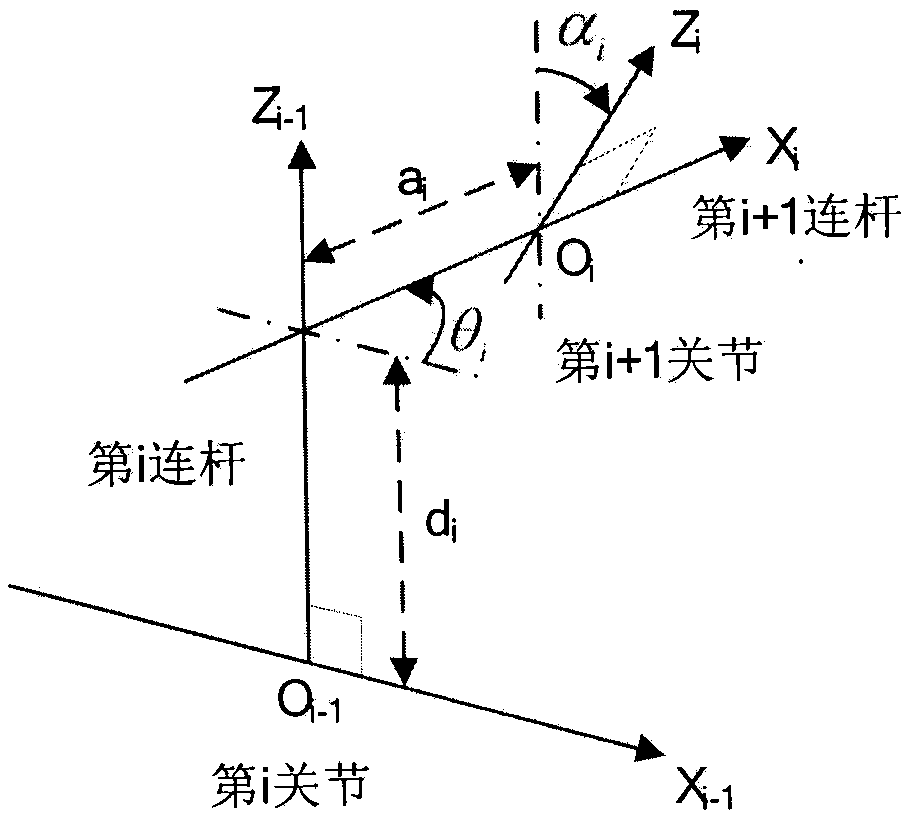

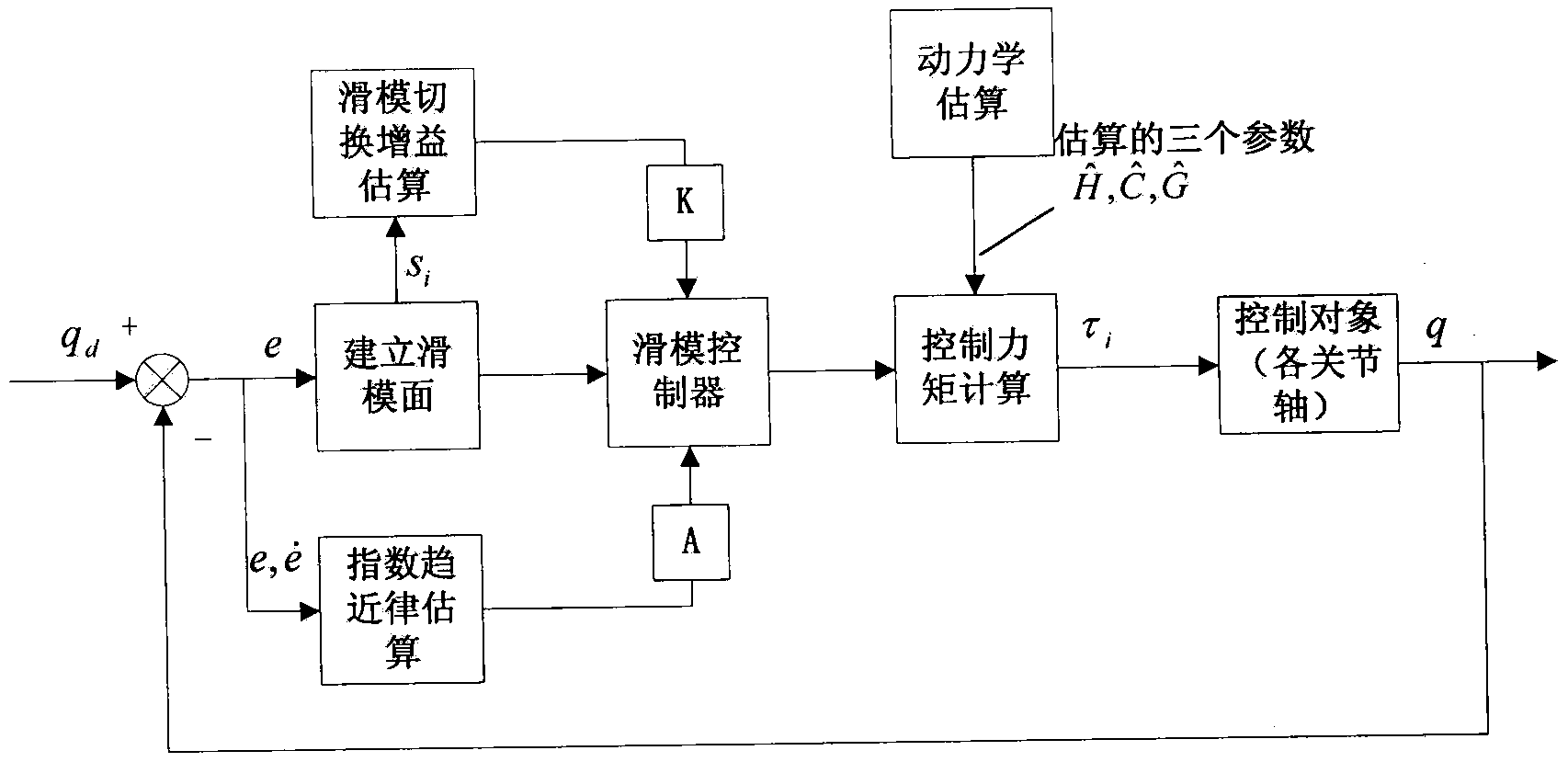

[0026] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

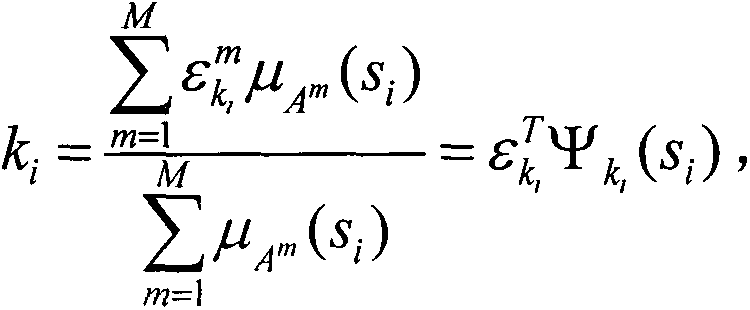

[0027] The basic idea of the present invention is to provide an improved robot control method: it does not need to know the specific mathematical model of the controlled object; and it has strong robustness and high tracking accuracy; and it improves the initial pose due to a large range Torque jump and speed jump caused by deviation. The present invention first models the robot to estimate its dynamic model, and adopts a sliding mode nonlinear control method based on the calculation torque method to ensure strong robustness in the control; the robot sliding mode control will have chattering phenomenon, so the original The invention introduces the exponential approach law to effectively eliminate the chattering proble...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com