Method for precisely accessing to overprinting position of gravure press

A gravure printing machine, precise technology, applied in general parts of printing machinery, printing machines, rotary printing machines, etc., can solve the problems of waste of printing substrates, low production efficiency, and increased production costs, so as to achieve high production efficiency and avoid Production costs, effects of avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

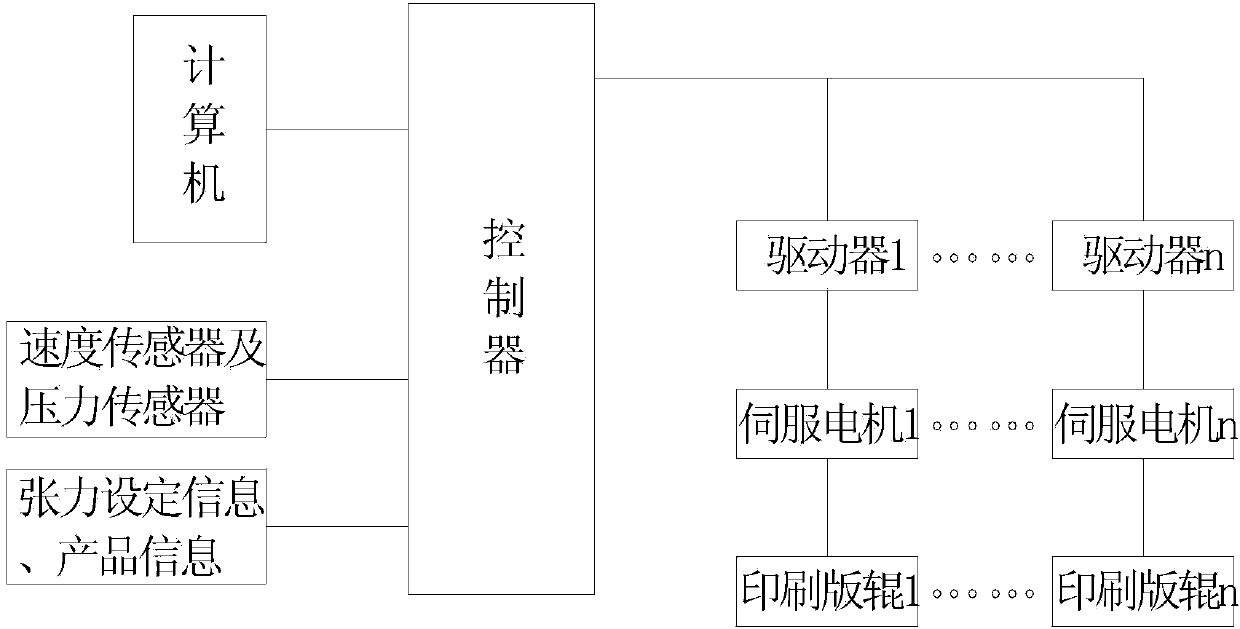

[0021] Such as figure 1 As shown, a kind of gravure printing machine of the present invention accurately enters the method for overprinting position, comprises the following steps:

[0022] a. Multiple servo motors are arranged so that the servo motors are connected to the printing plate rollers in one-to-one correspondence, that is, the number of servo motors is the same as the number of printing plate rollers, and one servo motor is connected to one printing plate roller.

[0023] b. Multiple drivers are set up so that the drivers and servo motors are connected in one-to-one correspondence, that is, the number of servo motors is the same as the number of drivers, and one servo motor is connected to one driver.

[0024] c. Set a controller so that multiple drives are connected to the controller, that is, multiple drives are connected to the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com