Multi-channel conveying device and method suitable for small-scale agricultural product intelligent sorting machine

A technology for conveying devices and agricultural products, which is applied to conveyor objects, transportation and packaging, etc., can solve the problems of large structure, high cost of sorting equipment, and difficulty in promoting machine vision sorting technology, and achieve the effect of improving sorting efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

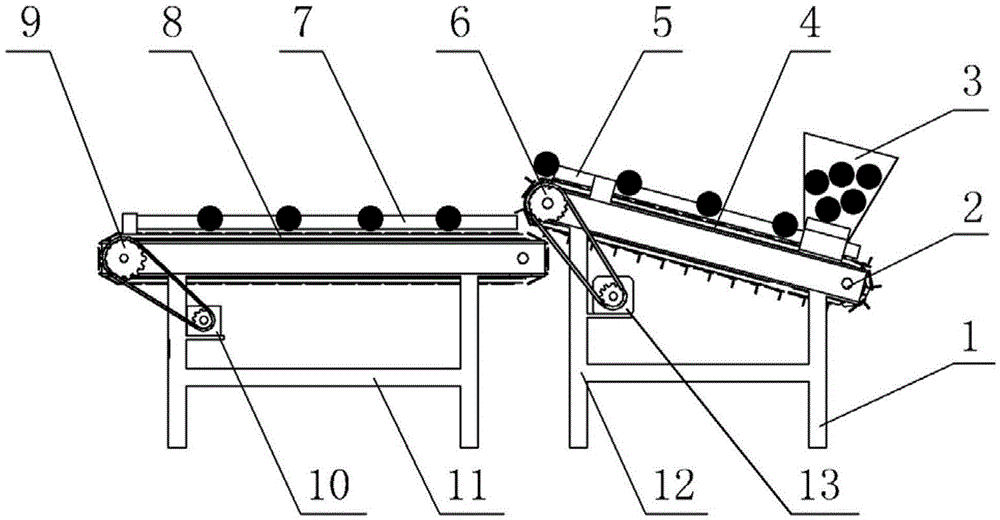

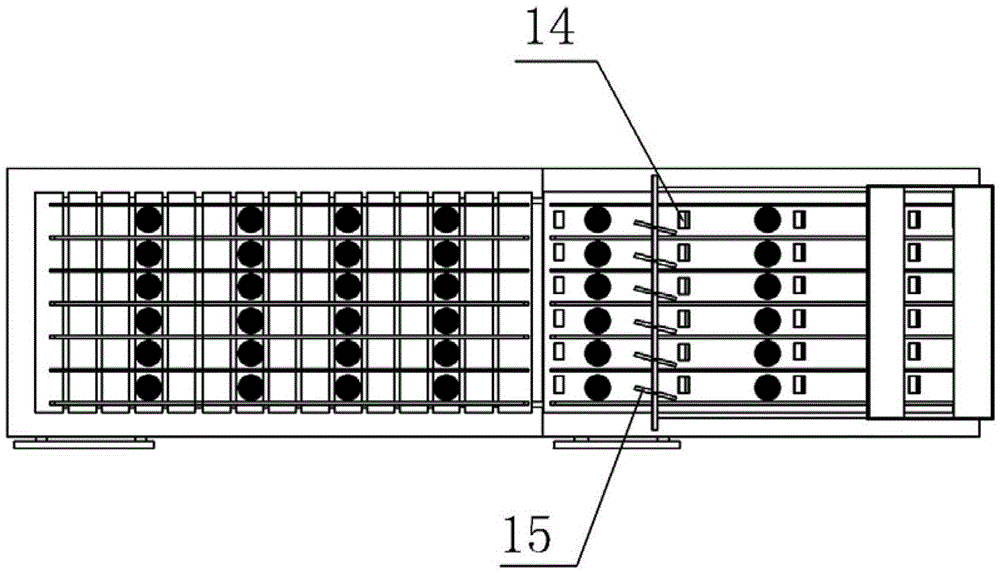

[0029] Such as figure 1 , figure 2 As shown, a multi-channel conveying device suitable for a small-scale intelligent sorter of agricultural products includes a material inclined conveying system and a material horizontal conveying system, and the material inclined conveying system and the material horizontal conveying system are sequentially connected.

[0030] The material inclined conveying system includes a first frame 1, a feed box 3, an inclined conveyor belt 4, an inclined channel dividing plate 5, a material baffle 14, rollers, a first speed regulating motor 13 and a blocking brush 15, and the inclined conveyor belt 4 is surrounded by Between the first driven roller 2 and the second driven roller 6, the adjustable speed motor 13 can be adjusted to control the running speed of the inclined conveyor belt 4, and the inclined channel dividing plate 5 divides 6 channels, and the material baffle plate 14 is evenly installed on the On the inclined conveyor belt 4, the feed b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com