Oxidized esterified composite modified starch and preparation method thereof

A technology of compound modified starch and oxidative esterification, applied in the field of starch compound modification processing, can solve the problems of complicated preparation process, insufficient reaction, low degree of product esterification, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

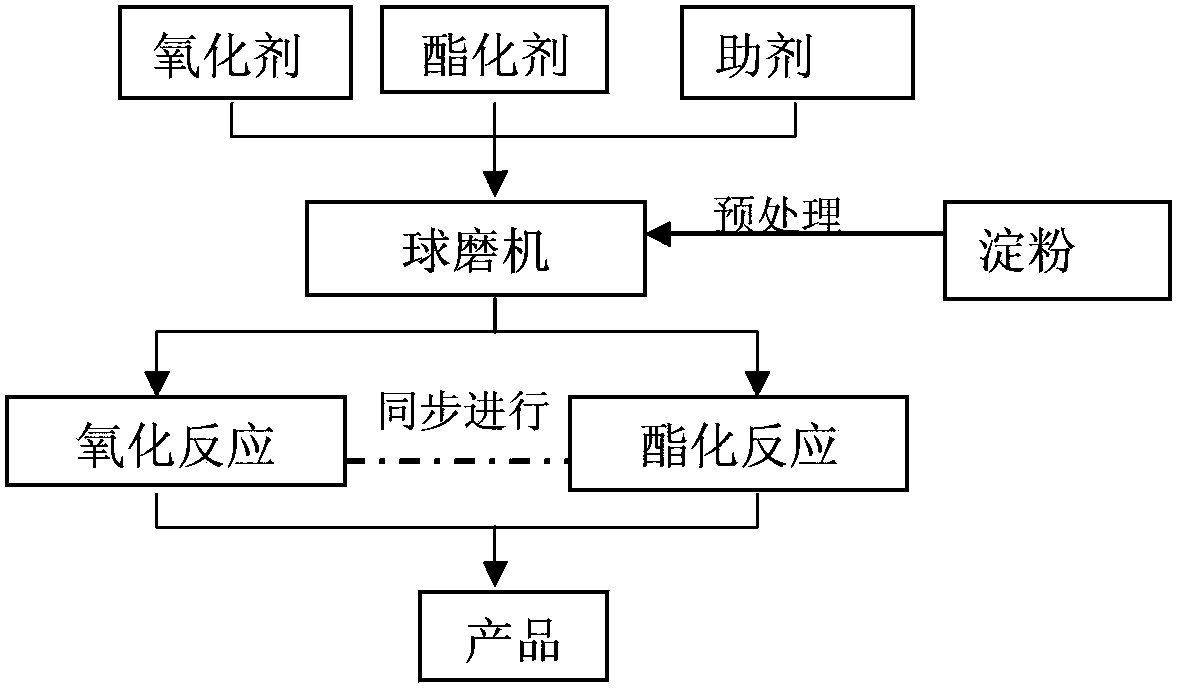

Method used

Image

Examples

Embodiment 1

[0029] In this example, according to the ratio of 60 mesh tapioca starch, sodium hypochlorite oxidizing agent, citric esterifying agent and copper sulfate auxiliary agent 162g: 0.5mol: 0.6mol: 1.62g, starch, oxidizing agent, esterifying agent, and auxiliary agent were weighed respectively. The weighed starch was pretreated: drying at 100°C for 45 minutes, so that the water content of the starch was 5.0%. The starch after pretreatment is mixed with oxidant, esterifying agent, auxiliary agent, under the condition of 500rpm, mixes 10min to obtain mixed material, and mixed material is put into mechanical ball mill, and stirring ball mill is the mechanical ball mill of built-in zirconium ball, and zirconium ball (total volume) to the mixed material ratio is 300mL: 100g, the temperature is controlled at 45°C, stirred and activated for 50 minutes, so that the mixed material undergoes oxidation reaction and esterification reaction at the same time, and after the reaction is completed, ...

Embodiment 2

[0032] In this embodiment, according to the ratio of 40 mesh corn starch, potassium permanganate oxidizing agent, acetic anhydride esterifying agent, and potassium carbonate auxiliary agent, the ratio of 162g: 0.6mol: 0.5mol: 5.0g, respectively weigh starch, oxidizing agent, esterifying agent, auxiliary agent agent. The weighed starch was pretreated: drying at 110°C for 30 minutes, so that the water content of the starch was 2.0%. The starch after pretreatment is mixed with oxidant, esterifying agent, auxiliary agent, and under the condition of 1500rpm, mixes 20min to obtain mixed material, and mixed material is put into mechanical ball mill, and stirring ball mill is the mechanical ball mill of built-in zirconium ball, and zirconium ball (total volume) to the mixed material ratio is 300mL: 100g, the temperature is controlled at 50°C, stirred and activated for 60 minutes, so that the mixed material undergoes oxidation reaction and esterification reaction at the same time, and ...

Embodiment 3

[0035] In this example, the starch, oxidizing agent, and esterifying Agents, auxiliaries. The weighed starch was pretreated: drying at 115°C for 60 minutes, so that the water content of the starch was 3.0%. The starch after pretreatment is mixed with oxidant, esterifying agent, auxiliary agent, under the condition of 1000rpm, mixes 5min to obtain mixed material, mixed material is packed in mechanical ball mill, and stirring ball mill is the mechanical ball mill of built-in zirconium ball, and zirconium ball (total volume) to the mixed material ratio is 300mL: 100g, the temperature is controlled at 80°C, stirred and activated for 40 minutes, so that the mixed material undergoes oxidation reaction and esterification reaction at the same time, and after the reaction is completed, the oxidized esterified composite modified starch is obtained.

[0036] The product prepared in this example is tested and analyzed, and the product has a degree of esterification of 0.05, a whiteness o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com