Long glass fiber reinforced nylon composite material and preparation method thereof

A nylon composite material and long glass fiber technology, which is applied in the field of polymer materials, can solve the problems of low elongation at break and the application effect needs to be improved, and achieve the effect that is beneficial to the application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] Correspondingly, the present invention also provides a preparation method of long glass fiber reinforced nylon composite material, comprising:

[0051] The material mixture is prepared by a melting method to obtain a long glass fiber reinforced nylon composite material;

[0052] The material mixture comprises:

[0053] 30wt%~65wt% nylon;

[0054]30wt%~60wt% long glass fiber;

[0055] 0.05wt%~10wt% metal salt or metal complex;

[0056] 0.1wt%~1wt% antioxidant;

[0057] 0.2wt% ~ 1wt% stabilizer;

[0058] 0.2wt% ~ 1wt% lubricant.

[0059] The present invention can effectively improve the tensile strength and elongation at break of the nylon material through the interaction between the metal ion in the metal salt or the metal complex and the polar group of the nylon polymer. A new path is provided.

[0060] In the embodiment of the present invention, according to the above weight percentage, the material mixture is put into the equipment for production by the melting...

Embodiment 1

[0073] Nylon 6 was vacuum-dried at a temperature of 110° C. for 6 hours.

[0074] With 61.5wt% vacuum-dried nylon 6, 2wt% lithium nitrate, 0.5wt% diphenylamine, 0.4wt% benzotriazole Tinuvin326 light stabilizer, 0.1wt% PolyAdHS02 thermal stabilizer and 0.5wt% % of polydimethylsiloxane (purchased from Toshiba, Japan) was sequentially added into a high mixer for mixing, the temperature was controlled at 60°C, and the mixing time was 10 minutes to obtain a mixture.

[0075] Put the mixture into a twin-screw extruder for melt extrusion to obtain a melt. The temperature of the twin-screw extruder has eight sections in total. The extrusion temperature of the first section is 210° C., and the second section is 220°C, the third stage is 230°C, the fourth stage is 240°C, the fifth, sixth and seventh stages are all 250°C, the melt temperature is 240°C, the head temperature is 235°C, and the speed of the main engine is 400r / min.

[0076] The melt is extruded into the impregnation mold,...

Embodiment 2

[0082] With 44wt% nylon 6, 50wt% long glass fiber, 5wt% lanthanum chloride (molecular formula is LaCl3, water content is less than 1%), 0.2wt% 2,6-tertiary butyl-4-methylphenol , 0.2wt% benzophenone KAIYUE / UV-531 light stabilizer, 0.2wt% PolyAdHS02 heat stabilizer and 0.4wt% polydimethylsiloxane (purchased from Toshiba, Japan) as raw material components, Following the same steps as in Example 1, a long glass fiber reinforced nylon composite material was obtained.

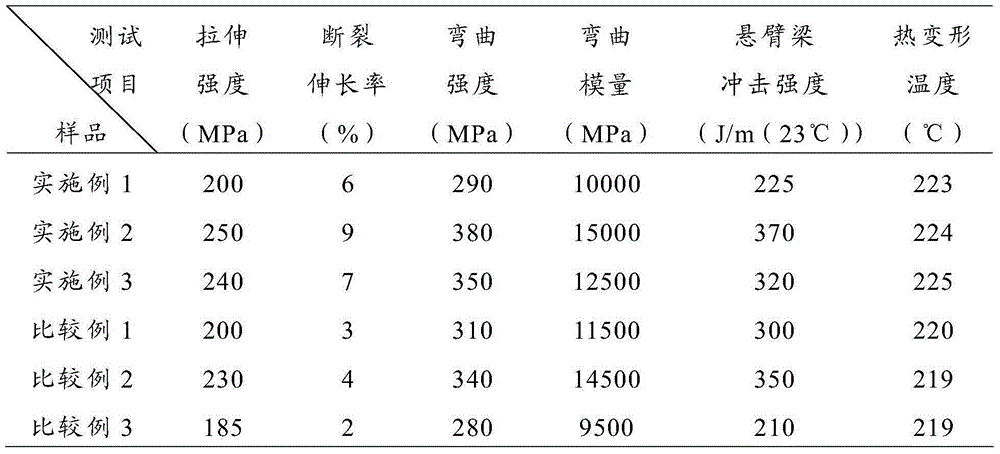

[0083] After the composite material was obtained, the mechanical properties of the sample were tested according to the method described above. The test results are shown in Table 1, and the results show that the composite material has good tensile properties.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com