Retarded-acid acidizing fluid

A technology of acidizing fluid and slow acid, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve problems such as clogging, affecting normal production of oil fields, and failing to achieve deep acidizing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

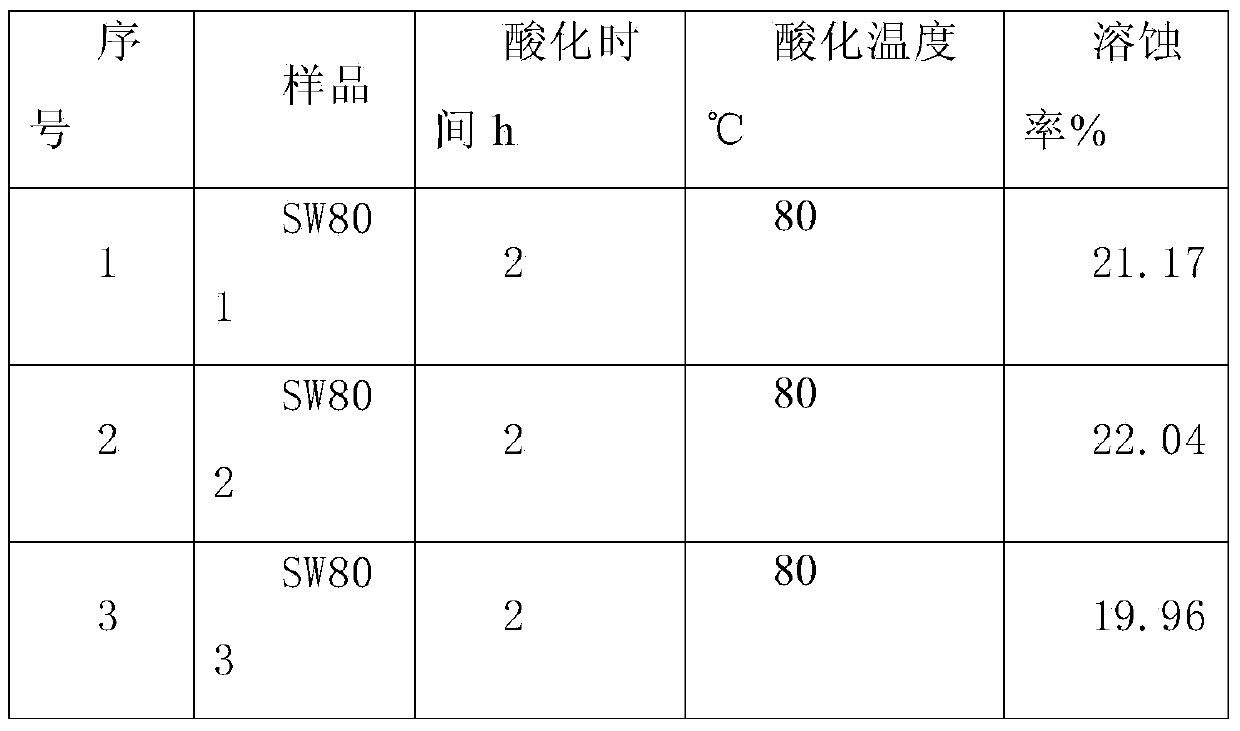

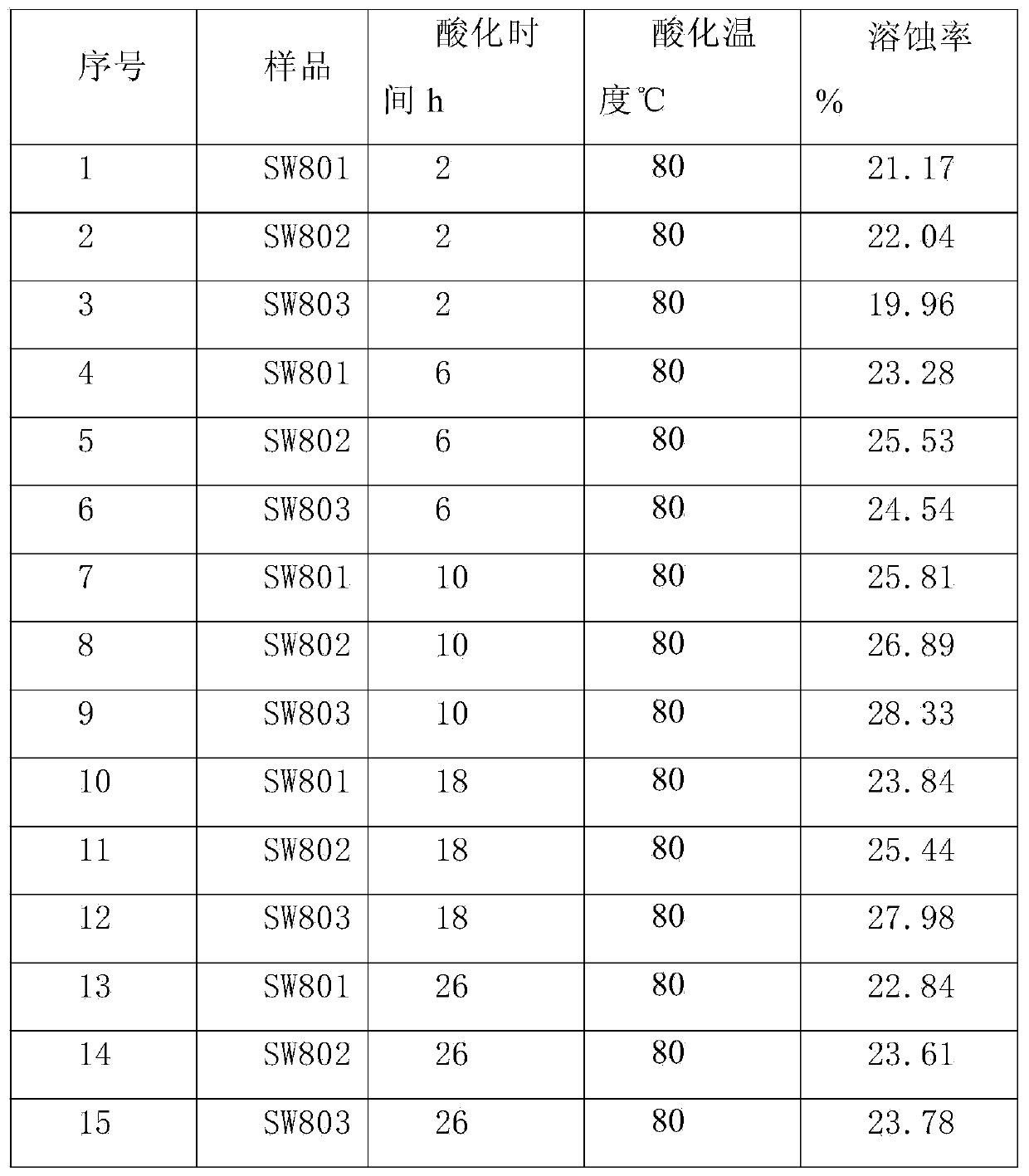

Embodiment 1

[0020] Hydrochloric acid, hydrofluoric acid, acidification retarder, acidification corrosion inhibitor, iron ion stabilizer, demulsification aid and clay stabilizer are used to prepare an aqueous solution. The weight percentage of each component in the aqueous solution is: hydrochloric acid, hydrofluoric acid, EL-21 acidification retarder, YHS-2 oil and gas well acidification corrosion inhibitor, CX-301 high temperature and powerful iron ion stabilizer, CX-307 broken Milk drainage aid, potassium chloride and water are 12%, 4%, 3%, 1%, 0.2%, 0.5%, 1% and 78.3% respectively. Mix the components at room temperature, shake well and let stand to prepare slow acid acidification solution.

Embodiment 2

[0022] Hydrochloric acid, hydrofluoric acid, acidification retarder, acidification corrosion inhibitor, iron ion stabilizer, demulsification aid and clay stabilizer are used to prepare an aqueous solution. The parts by weight of the components in the aqueous solution are: hydrochloric acid, hydrofluoric acid, EL-21 acidification retarder, YHS-2 oil and gas well acidification corrosion inhibitor, CX-301 high temperature and powerful iron ion stabilizer, CX-307 demulsification Drainage aid, potassium chloride and water were 14%, 4%, 2%, 1%, 0.2%, 0.5%, 1% and 77.3% respectively. Mix the components at room temperature, shake well and let stand to prepare slow acid acidification solution.

Embodiment 3

[0024] Hydrochloric acid, hydrofluoric acid, acidification retarder, acidification corrosion inhibitor, iron ion stabilizer, demulsification aid and clay stabilizer are used to prepare an aqueous solution. The parts by weight of the components in the aqueous solution are: hydrochloric acid, hydrofluoric acid, EL-21 acidification retarder, YHS-2 oil and gas well acidification corrosion inhibitor, CX-301 high temperature and powerful iron ion stabilizer, CX-307 demulsification Drainage aid, potassium chloride and water were 14%, 4%, 3%, 1%, 0.2%, 0.5%, 1% and 76.3% respectively. Mix the components at room temperature, shake well and let stand to prepare slow acid acidification solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com