A ring spinning frame spinning section strengthening device

A technology for strengthening device and spinning section, which is applied in the field of strengthening device for spinning section of ring spinning frame, which can solve the problems of weak control of twisting triangle area, increase of unit power consumption, easy occurrence of end breakage, etc., and achieve high false twisting efficiency , End-break reduction, and single-yarn twist reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions of the present invention are further described below with reference to the accompanying drawings and through specific embodiments.

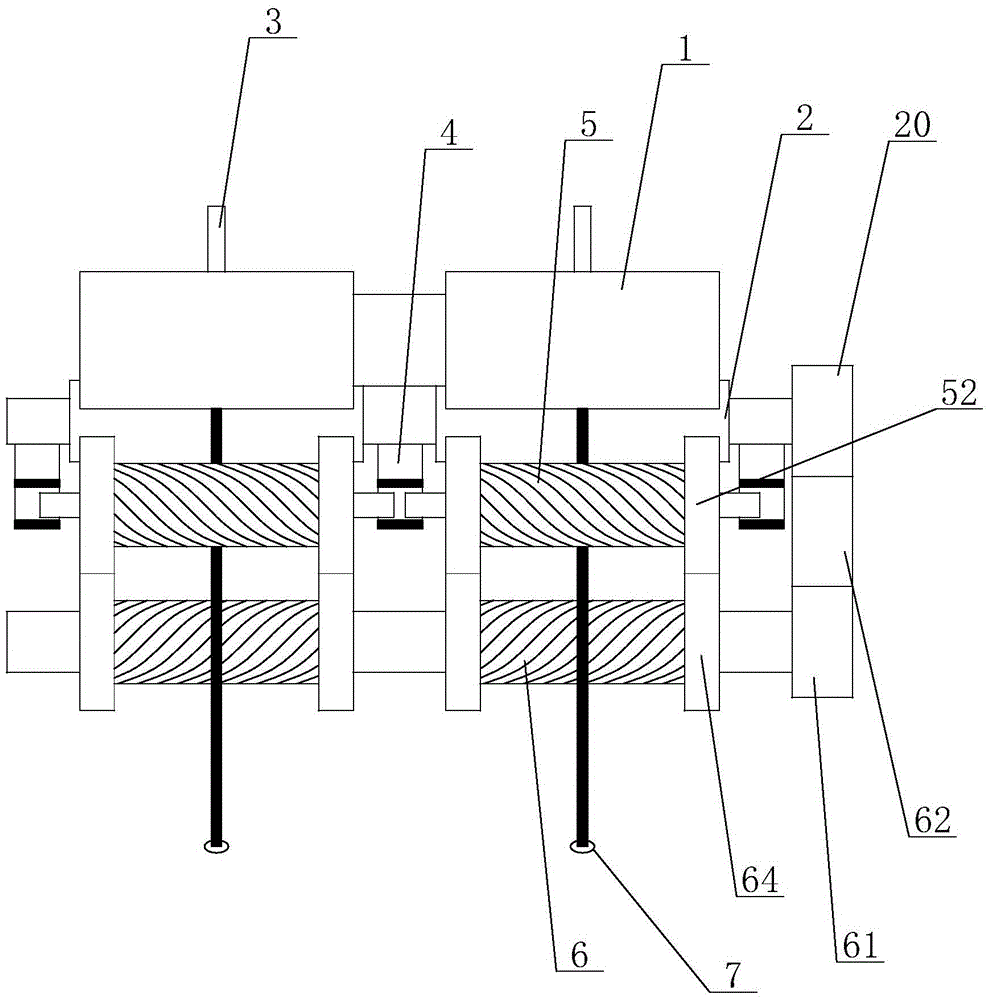

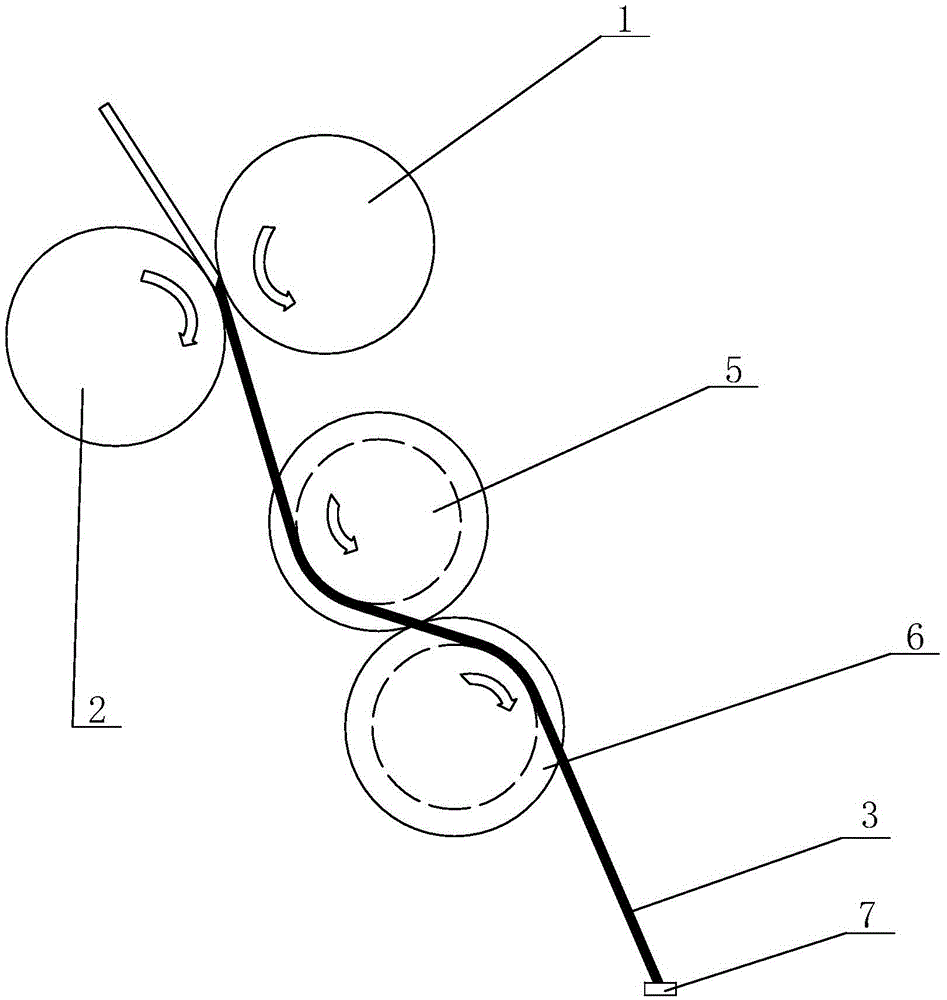

[0027] see Figure 1 to Figure 8 As shown, in this embodiment, a device for enhancing the spinning section of a ring spinning frame, taking Z-twisted yarn as an example, includes a front top roller 1 and a front roller 2, and the front top roller 1 and the front roller 2 form a yarn The front jaw of the bar 3, and one end of the front roller 2 is connected with a front roller gear 20, and a plurality of helical press rollers 5 are installed downstream of the front jaw through the helical press roller support 4. The helical press rollers 5 includes a pressure roller shaft 50 rotatably arranged on the spiral pressure roller support 4, a pressure roller sleeve 51 is detachably fixed on the pressure roller shaft 50, and the surface of the pressure roller sleeve 51 is provided with multiple heads Right helical pattern, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com