Amino-silicone oil softener containing fluorine group and quaternary ammonium salt group as well as preparation method and application thereof

A technology of quaternary ammonium salt group and amino silicone oil, which is applied in textiles and papermaking, fiber treatment, plant fiber, etc. It can solve the problems of increasing cost and compatibility of finishing agents, and achieves low toxicity, avoiding compounding and compatibility problems, low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

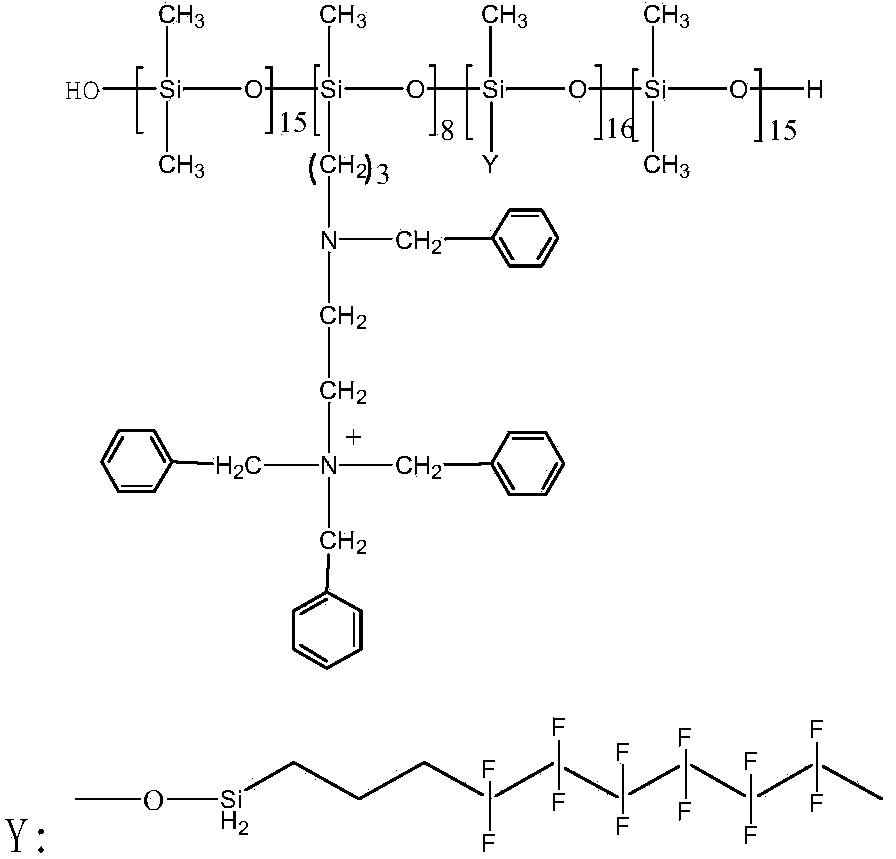

Embodiment 1

[0036] A kind of preparation method of the amino silicone oil softening agent of fluorine-containing group and quaternary ammonium salt group, comprises the steps:

[0037] (1) Add 30g of low-viscosity hydroxyl-terminated polysiloxane (linear body) into a four-necked flask equipped with a condenser tube, a thermometer and a stirring paddle. Stir in a water bath and heat up to 85°C, add 1.0 g of N-(β-aminoethyl)-γ-aminopropylmethyldimethoxysilane, dodecafluoroheptylpropylmethyldimethoxysilane Silane 13.0g, after two hours of reaction, add N-(β-aminoethyl)-γ-aminopropylmethyldimethoxysilane 1.0g and dodecafluoroheptylpropylmethyldimethoxysilane 13.0 g. In this way, add N-(β-aminoethyl)-γ-aminopropylmethyldimethoxysilane and dodecafluoroheptylpropylmethyldimethoxysilane every two hours, adding four times in total . Two hours after the last feeding, the temperature was lowered and the material was discharged to obtain light yellow transparent fluorine-containing amino silicone ...

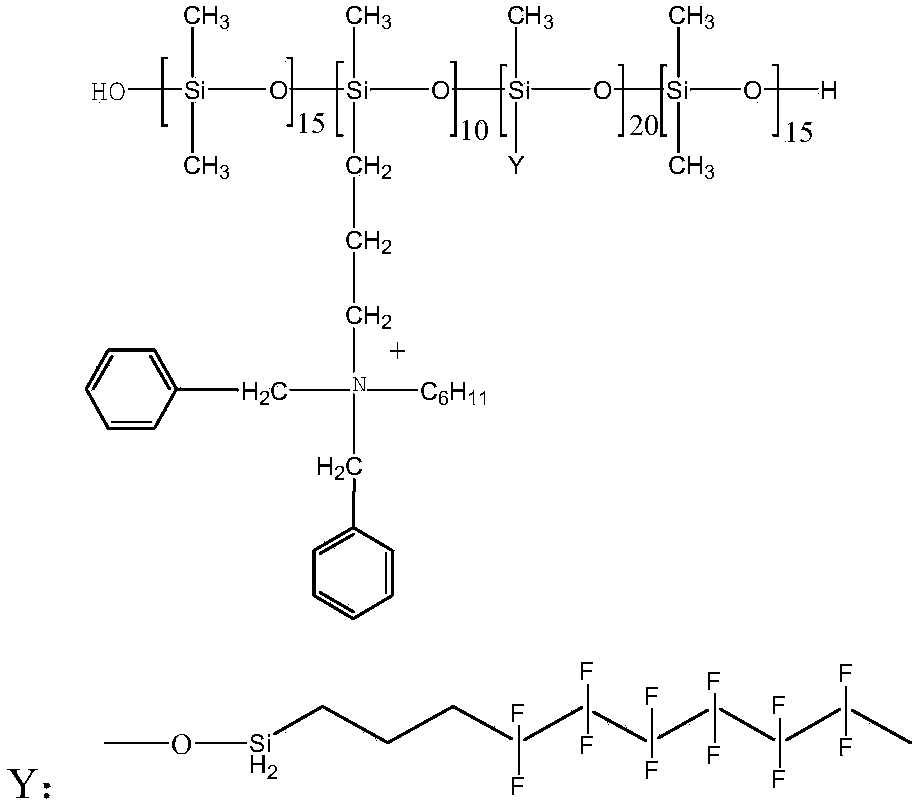

Embodiment 2

[0040] A kind of preparation method of the amino silicone oil softening agent of fluorine-containing group and quaternary ammonium salt group, comprises the steps:

[0041] (1) Add 30g of low-viscosity hydroxyl-terminated polysiloxane (linear body) into a four-necked flask equipped with a condenser tube, a thermometer and a stirring paddle. Stir in a water bath and heat up to 85°C, add 2.3 g of N-cyclohexyl-γ-aminopropylmethyldimethoxysilane and 13.0 g of dodecafluoroheptylpropylmethyldimethoxysilane to it, and react Two hours later, 2.3 g of N-cyclohexyl-γ-aminopropylmethyldimethoxysilane and 13.0 g of dodecafluoroheptylpropylmethyldimethoxysilane were added. In this way, N-cyclohexyl-γ-aminopropylmethyldimethoxysilane and dodecafluoroheptylpropylmethyldimethoxysilane were added every two hours for a total of four additions. Two hours after the last feeding, the temperature was lowered and the material was discharged to obtain light yellow transparent fluorine-containing ami...

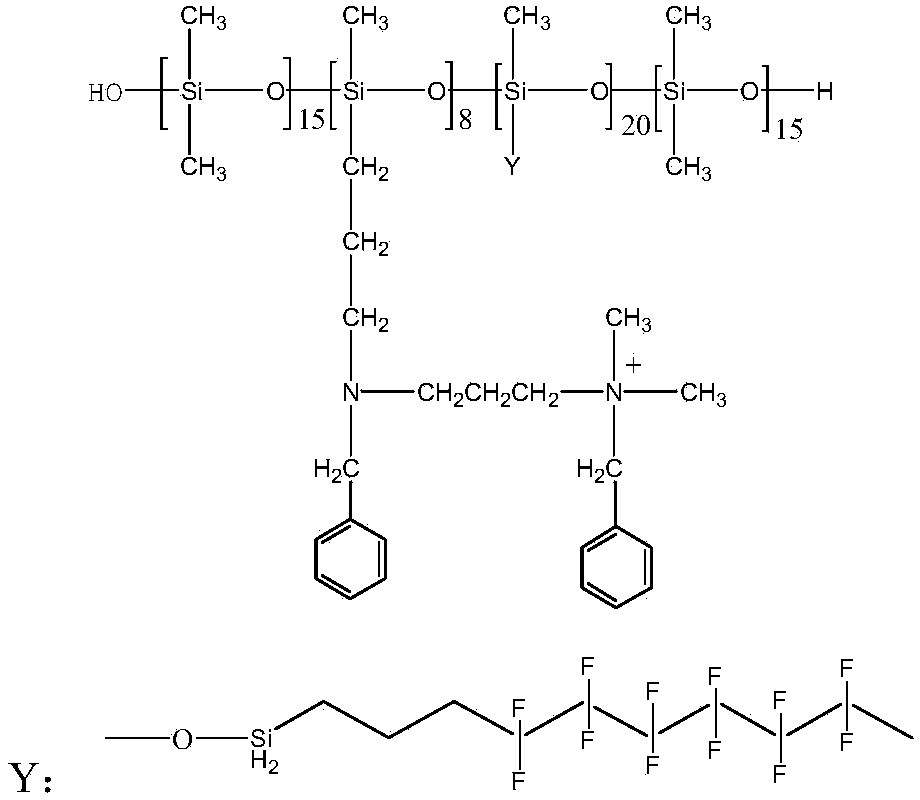

Embodiment 3

[0044] A kind of preparation method of the amino silicone oil softening agent of fluorine-containing group and quaternary ammonium salt group, comprises the steps:

[0045] (1) Add 30g of low-viscosity hydroxyl-terminated polysiloxane (linear body) into a four-necked flask equipped with a condenser tube, a thermometer and a stirring paddle. Stir in a water bath to raise the temperature to 85°C, add 1.1 g of N-(γ,-dimethylaminopropyl)-γ-aminopropylmethyldimethoxysilane, dodecafluoroheptylpropylmethyldimethoxysilane, Methoxysilane 12.3g, after two hours of reaction, add N-(γ,-dimethylaminopropyl)-γ-aminopropylmethyldimethoxysilane 1.1g, dodecafluoroheptylpropyl methyl Dimethoxysilane 12.3g. In this way, N-(γ,-dimethylaminopropyl)-γ-aminopropylmethyldimethoxysilane and dodecafluoroheptylpropylmethyldimethoxysilane were added every two hours for a total of Add four times. Two hours after the last feeding, the temperature was lowered and the material was discharged to obtain lig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com