Preloading structural part for high and large formwork support system

A support system, stacking preloading technology, applied to the joints of formwork/formwork/work frame, formwork/formwork/work frame, construction components on-site preparation, etc., can solve the inaccurate control of preloading data , template support system collapse, extended construction period, etc., to achieve the effect of accelerating preloading work efficiency, large unit area load, and reducing hoisting workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

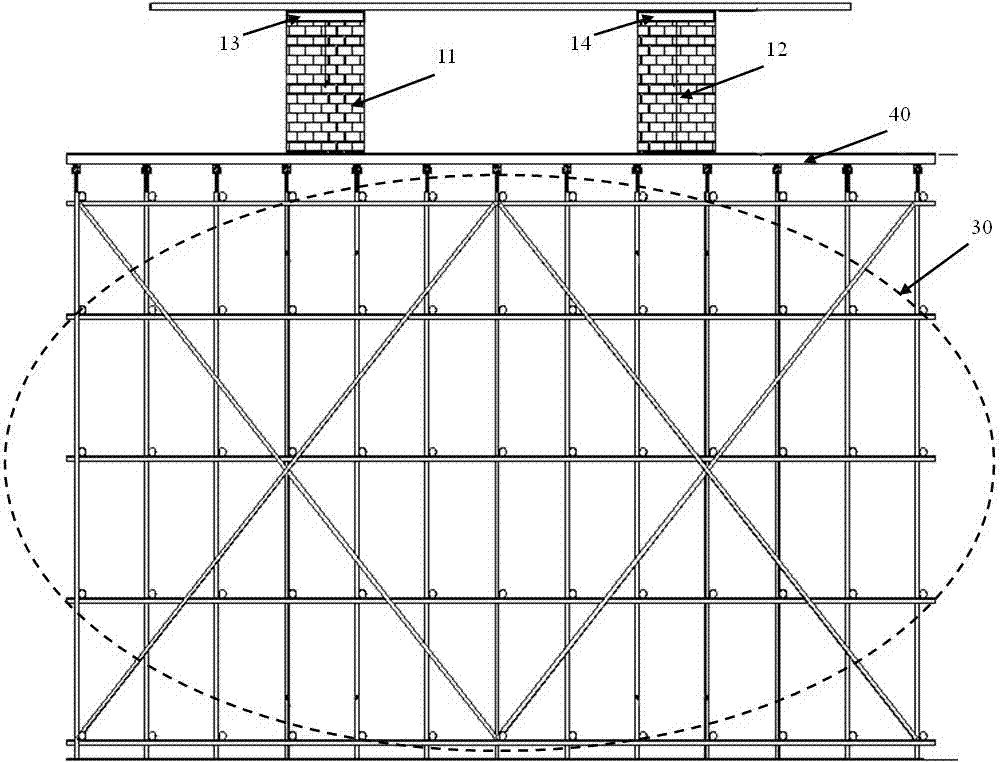

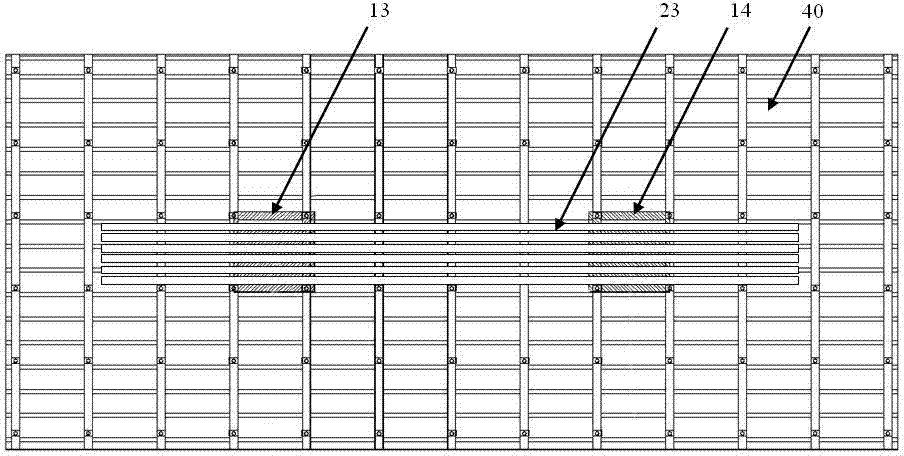

[0029] see figure 1 , used for the stacked preloaded structural parts of the tall formwork support system, including brick pier components and preloaded load components;

[0030] The brick pier assembly is composed of a first brick pier block 11 and a second brick pier block 12; wherein, the first brick pier block 11 is a rectangular column with a length of 1 meter, a width of 1 meter, and a height of 1.2 meters. The top of pier block 11 is provided with first smoothing layer 13; Smoothing layer 14; the top surface of the first smoothing layer 13 is horizontal to the top surface of the second smoothing layer 14; the center of the first brick pier 11 and the center of the second brick pier 12 are 4.5 meters apart;

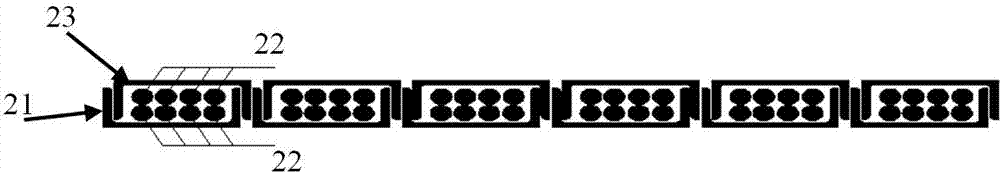

[0031] The preloaded load components are composed of preloaded load units, and the preloaded load components are composed of 2 to 10 preloaded load units arranged horizontally;

[0032] The preloaded load unit is approximately a rectangular block, and is composed...

Embodiment 2

[0036] see Figure 4 , used for the stacked preloaded structural parts of the tall formwork support system, including brick pier components and preloaded load components;

[0037] The brick pier assembly is composed of a first brick pier block 11 and a second brick pier block 12; wherein, the first brick pier block 11 is a rectangular column with a length of 1 meter, a width of 1 meter, and a height of 1.5 meters. The top of pier block 11 is provided with the first plastering layer 13; Smoothing layer 14; the top surface of the first smoothing layer 13 is horizontal to the top surface of the second smoothing layer 14; the center of the first brick pier 11 and the center of the second brick pier 12 are 4.5 meters apart;

[0038] The preloaded load components are composed of preloaded load units, and the preloaded load components are composed of six preloaded load units arranged horizontally;

[0039]The preloaded load unit is approximately a rectangular block, and is composed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com