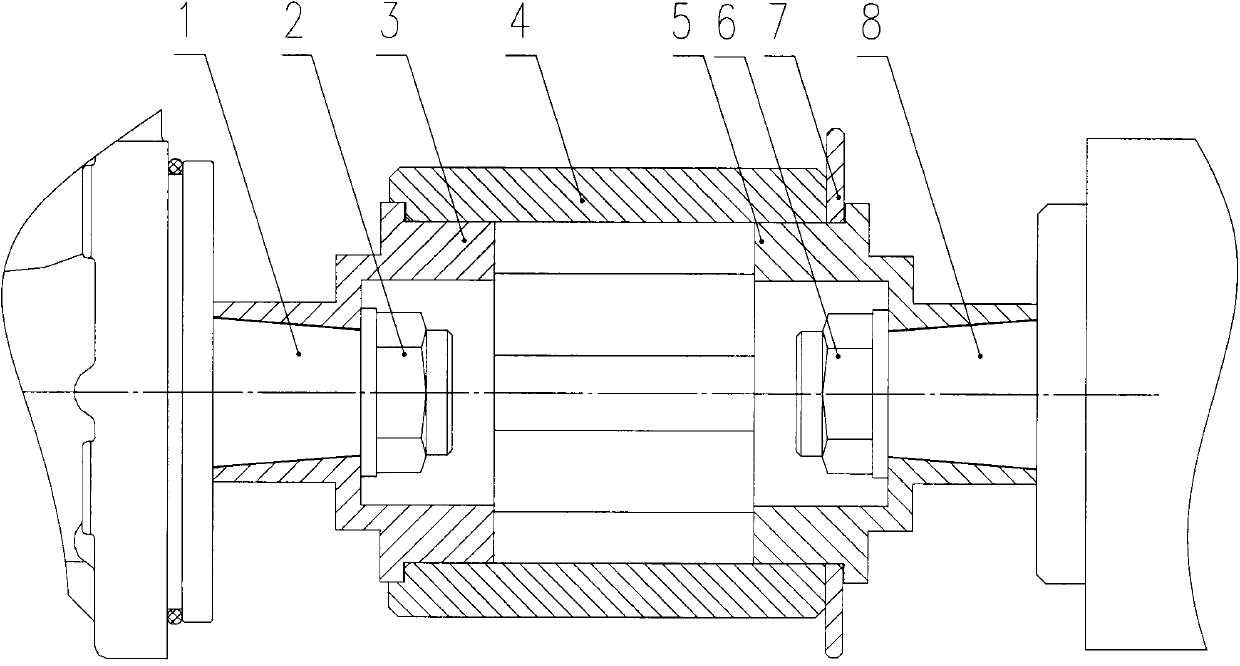

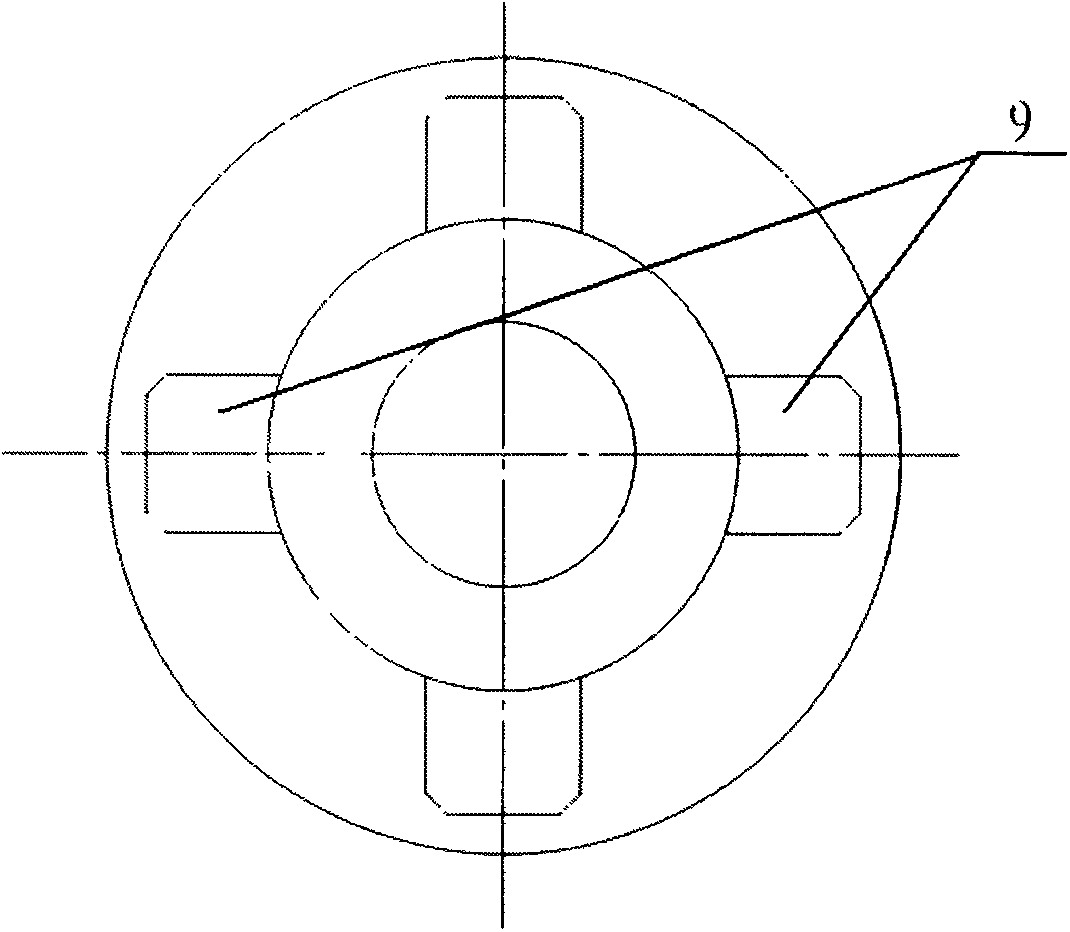

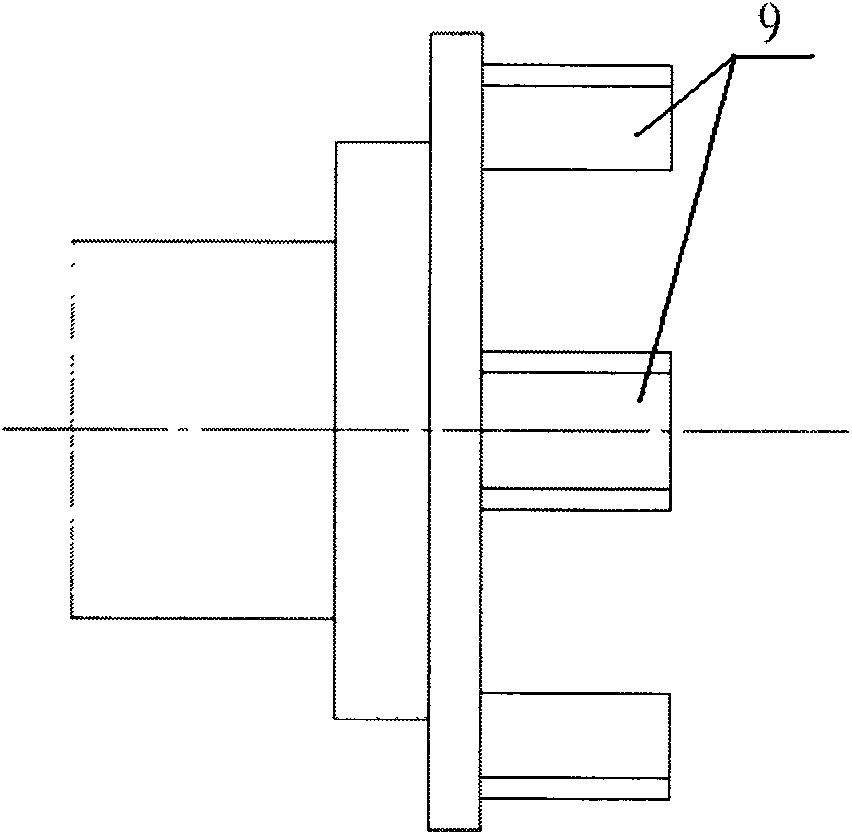

Cross elastic connection device of high-pressure pump shaft and transmission shaft of engine

A technology of elastic connection and cross connection, which is applied to engine components, machines/engines, fuel injection devices, etc., can solve the problems of high processing cost and complex connection structure, and achieve the effects of fast processing, convenient installation and simple design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] According to the size of the cone surface of the shaft head of the high-pressure oil pump in the high-pressure common rail system, the internal profile of the cross claw of the high-pressure pump shaft is processed, and the bonding degree of the two cone surfaces is ensured to be greater than 85% during the processing;

[0022] Install the processed cross claw of the driving shaft and the driving shaft. During the installation process, the coloring inspection of the cone surface should be carried out to ensure the fit of the two cone surfaces. There is no need for positioning between the cone surfaces, and the drive shaft compression bolts are used to compress the two. There is no phase requirement between the drive shaft cross claw and the drive shaft; install the processed high-pressure oil pump shaft cross claw with the high-pressure oil pump shaft, and install During the process, the color inspection of the cone surface should be carried out to ensure the fit of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com