Active capacitance pen, capacitance touch panel and touch device

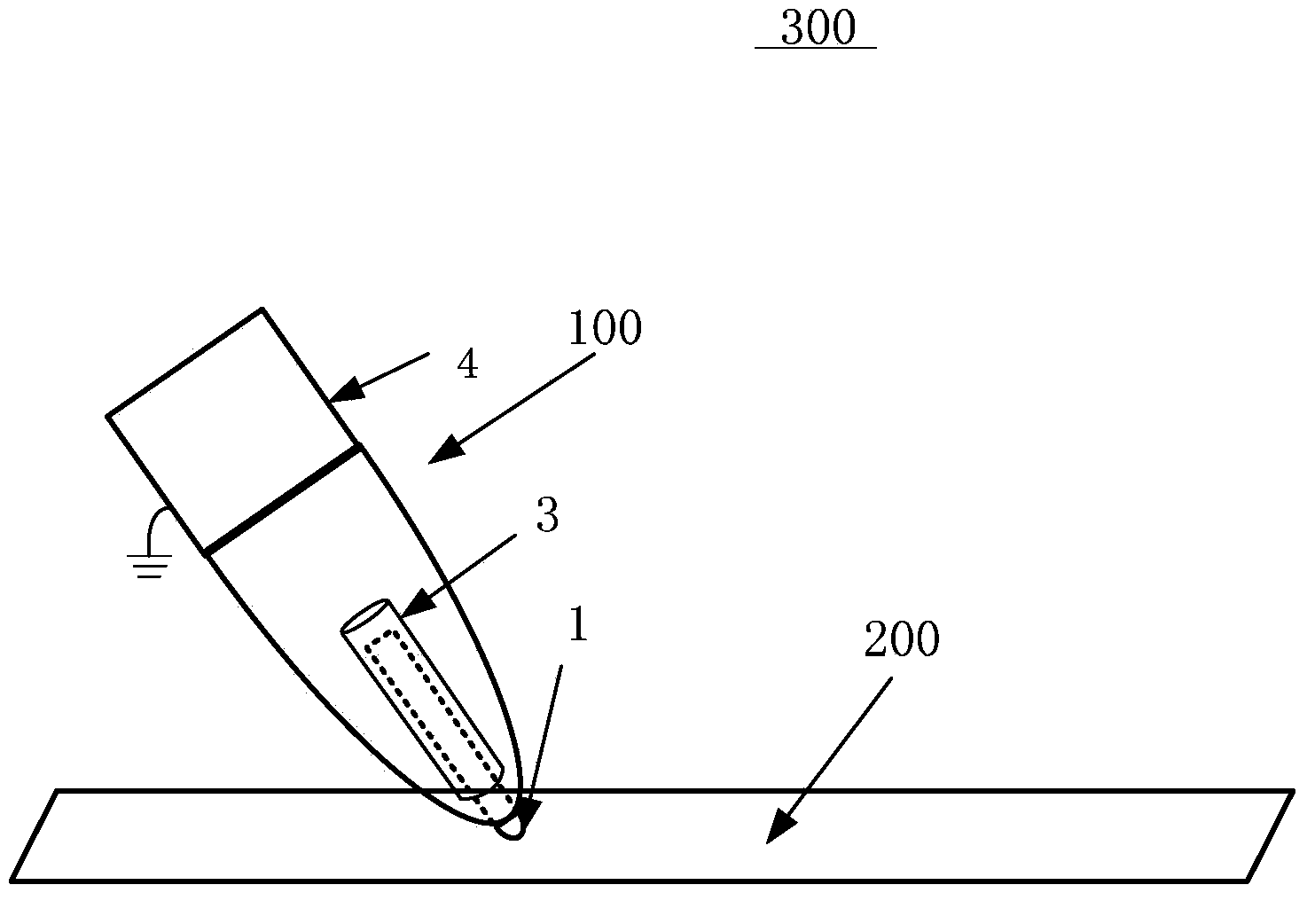

A capacitive touch panel and capacitive pen technology, which is applied to the input/output process of electrical digital data processing, instruments, and data processing, etc., can solve the problem that the capacitive touch screen cannot determine the touch position, cannot achieve the effect of writing pictures, and can write smoothly. It can improve the stability and anti-interference, increase the electric field, and achieve the effect of good support.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

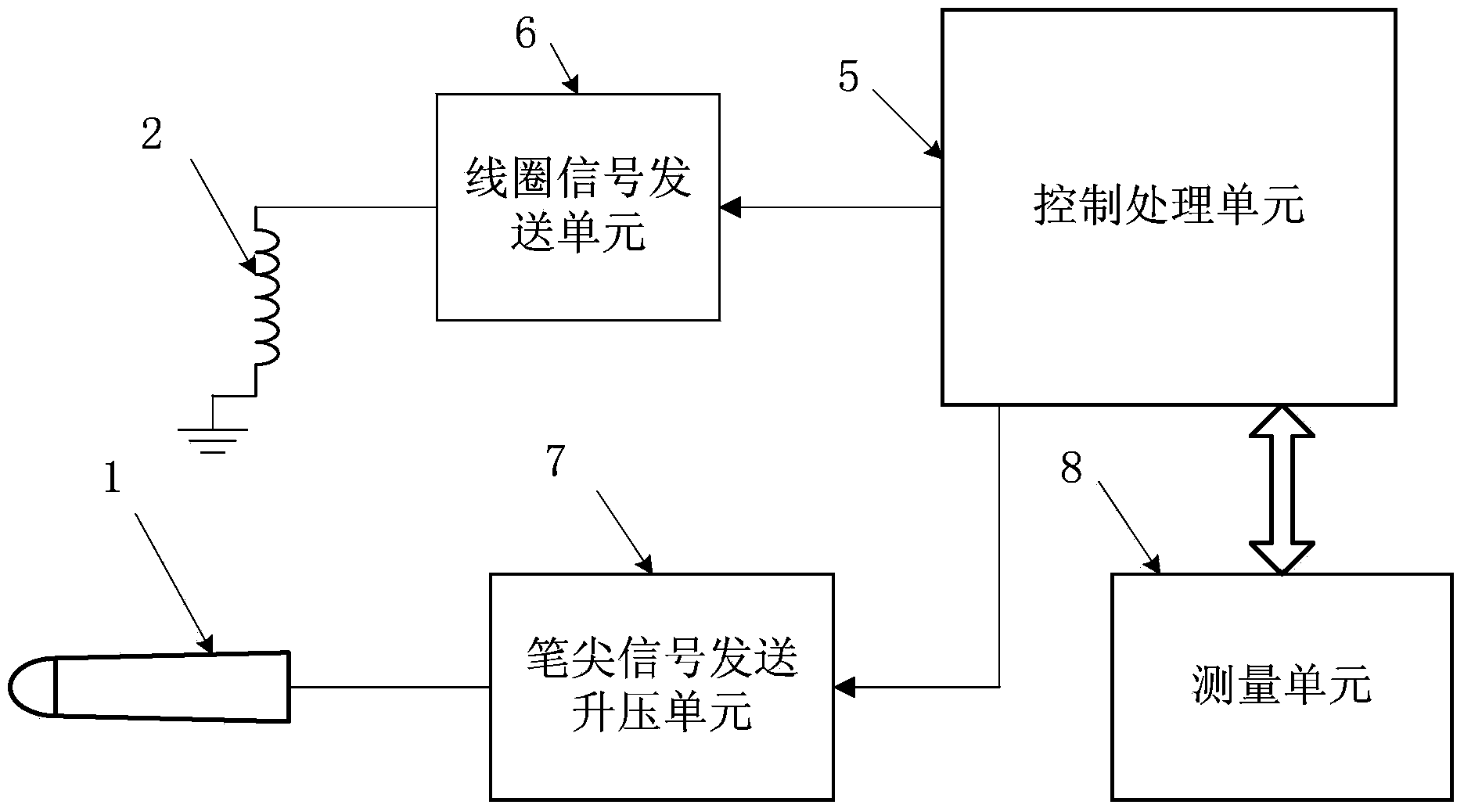

[0070] Example 1. In this example, the second sending unit 2 (sending coil) of the capacitive pen 100 only sends command signals, but does not send synchronization signals. The specific coordination process of the capacitive stylus 100 and the capacitive touch panel 200 is as follows.

[0071] The working process of the capacitive pen 100:

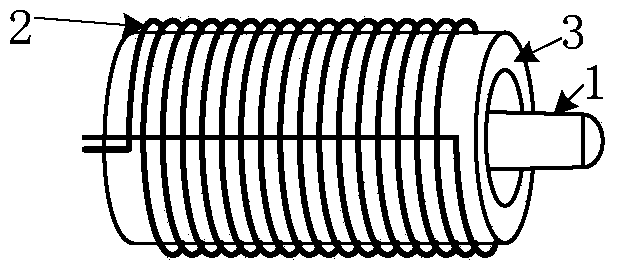

[0072] Since the capacitive stylus 100 has no device for receiving commands, the capacitive stylus 100 does not know whether it is close to the capacitive touch panel 200 . The capacitive pen 100 works cyclically according to a fixed workflow. The first sending unit 1 (pen tip) of the capacitive pen 100 sends a high-voltage signal, and the second sending unit 2 (sending coil) sends a command signal. The working process includes the following steps:

[0073] Step a: The sending coil in the pen sends command A, which means that the pen tip will send n in-phase pulses later, and then the pen tip will send n in-phase pulses;

[0074] Step b:...

example 2

[0092] Example 2. In this example, the second sending unit 2 (sending coil) of the capacitive pen 100 sends command signals and synchronization signals. The specific coordination process of the capacitive pen 100 and the capacitive touch panel 200 is as follows.

[0093] The working process of the capacitive pen 100 is:

[0094] Since the capacitive stylus 100 has no device for receiving commands, the capacitive stylus 100 does not know whether it is close to the capacitive touch panel 200 . The capacitive pen 100 works cyclically according to a fixed workflow. The first sending unit 1 (pen tip) of the capacitive pen 100 sends high-voltage signals, and the second sending unit 2 (sending coil) sends command signals and synchronization signals. The working process includes the following steps:

[0095] Step a: The sending coil in the capacitive pen 100 sends command A, which means that the pen tip will send n in-phase pulses later, and then the sending coil in the pen sends n sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com