Machining method and machining tool for machining curved workpiece surface, and workpiece

A technology for workpiece surface and machining tools, applied in the field of workpiece surface machining tools, can solve problems such as engine damage and destruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

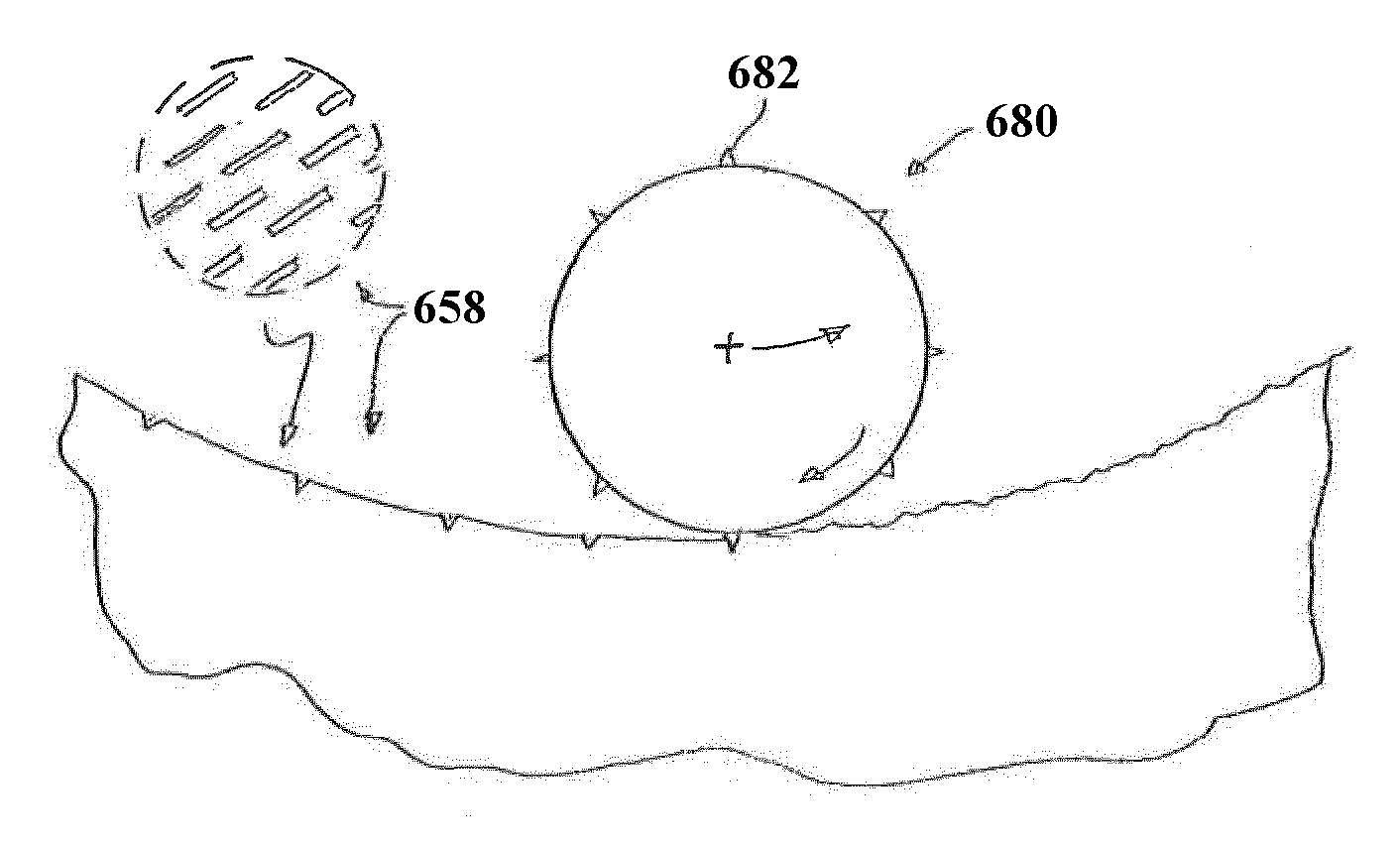

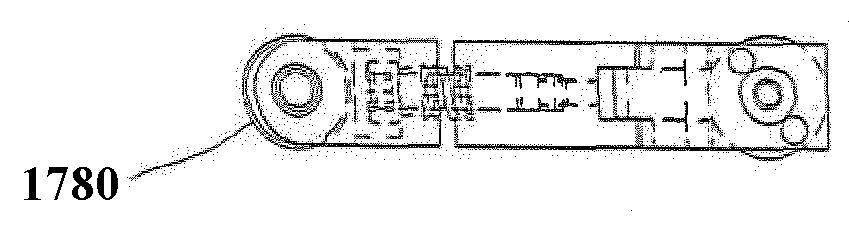

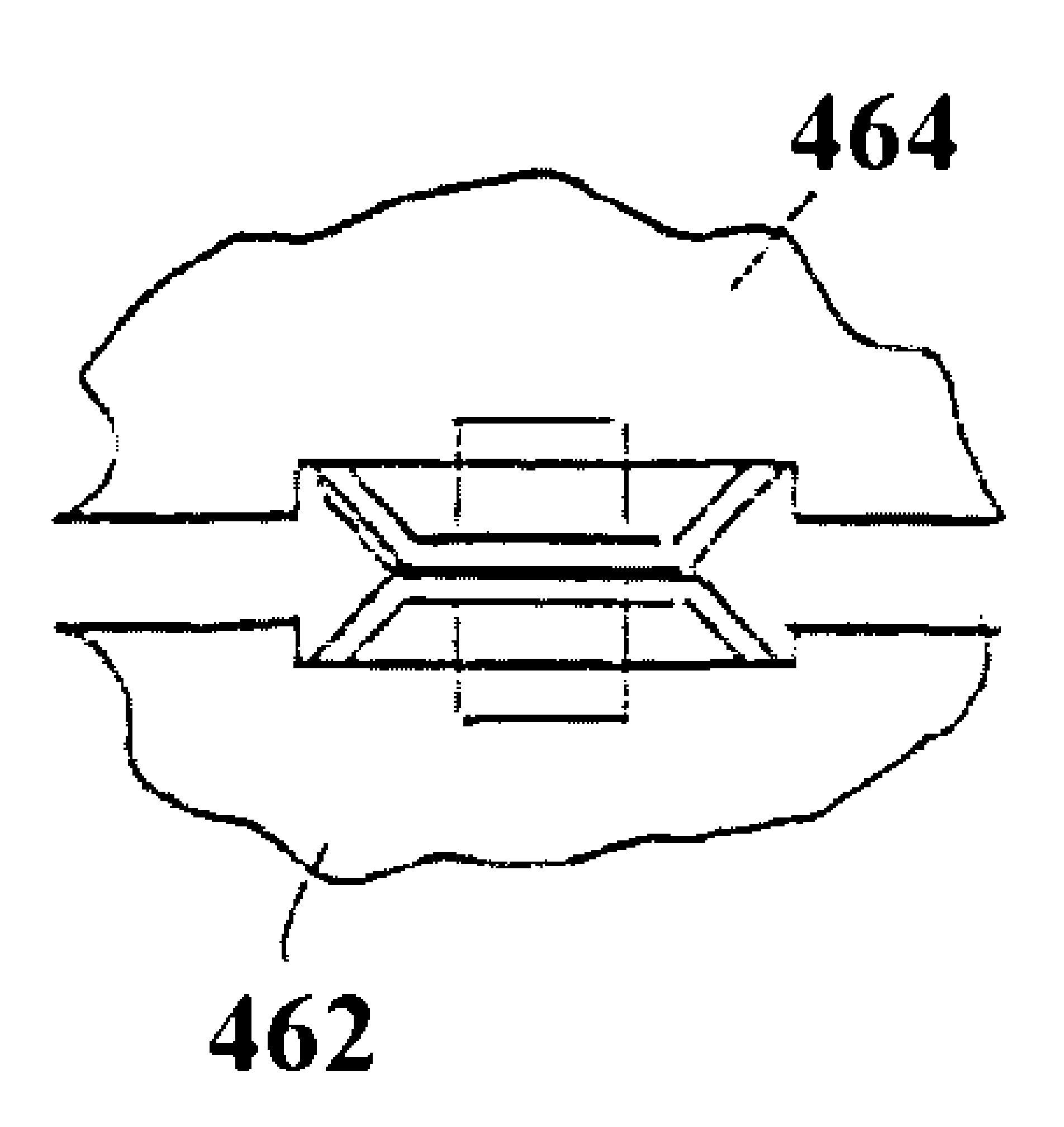

[0077] exist figure 1 A schematic axial section through a first embodiment of the machining tool 100 for rolling is shown in . The machining tool (rolling tool) is designed for machining largely cylindrical inner surfaces on bores, in particular for producing cylinder running surfaces for internal combustion engines. The machining tool has a substantially rotationally symmetrical tool body 110 made of steel, the axis of which defines a tool axis 112 . The end of the tool body facing the spindle is formed by a tapered coupling section 114 with a cylindrical outer contour, in which radially protruding entrainment pins 116 are mounted at diametrically opposite positions. By means of these coupling devices, the machining tool can be coupled to the free end of the drive rod 150 of the honing machine, which is provided with an angled receiving groove for the driving pin. The coupled machining tool is not rigidly connected to the driven honing spindle of the honing machine, but can...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com