scraping tool

A technology for scraping tools and cutting edges, which is applied in the direction of manufacturing tools, metal processing equipment, metal extrusion cleaning equipment, etc., can solve the problems of complex devices, shortened tool life, and large size, and achieve the effect of reducing unevenness and suppressing vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below, according to the attached Figure 1 to Figure 7 One embodiment of the present invention will be described.

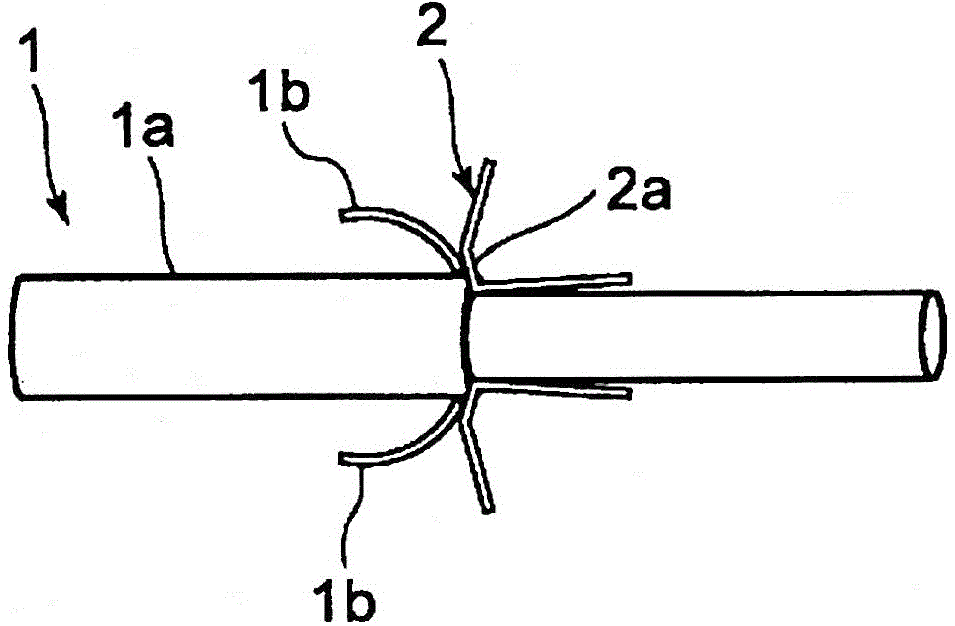

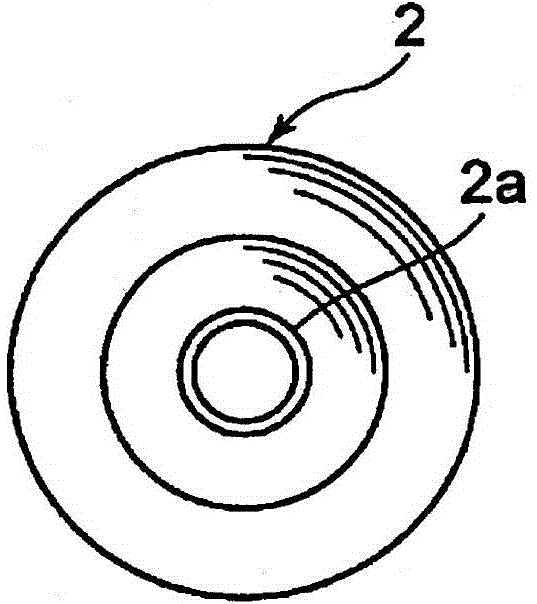

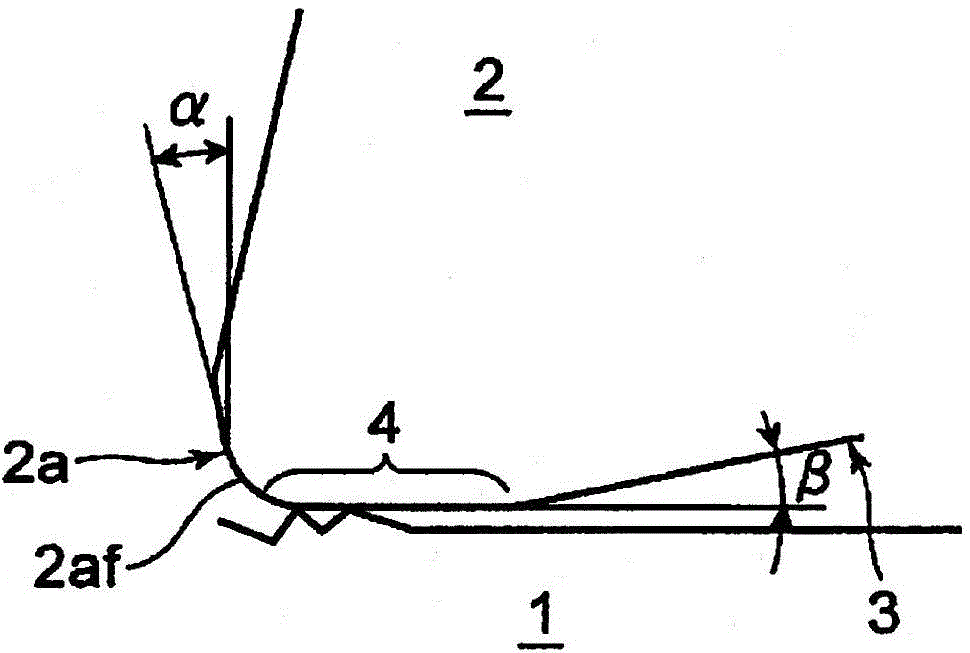

[0033] figure 1 It is an explanatory drawing which schematically shows the shaving process of the wire rod using the shaving tool of one embodiment. The steel wire material (hereinafter referred to as "wire material") 1 as the workpiece is usually arranged on the output side of the scraping tool 2 ( figure 1 under the action of traction generated by the winder (not shown) on the right side of the figure 2 The scraping tool 2 of the shape shown. The surface layer 1a of the wire rod 1 is cut over the entire circumference by the cutting edge 2a. Surface defects of the wire rod 1 are removed together with the chips 1b. Such as image 3 As shown, the cutting edge 2a of the scraping tool 2 for scraping the surface of the wire rod 1 is formed so that the rake angle α becomes a negative value in the range of -5° to -30°. In addition, the cutting edge 2af o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com