Streptavidin-bonded magnetic particles and manufacturing method for same

A streptavidin, magnetic particle technology, applied in biochemical equipment and methods, material testing products, instruments, etc., can solve the problems of reduced washing efficiency, reduced sensitivity, and increased turbidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

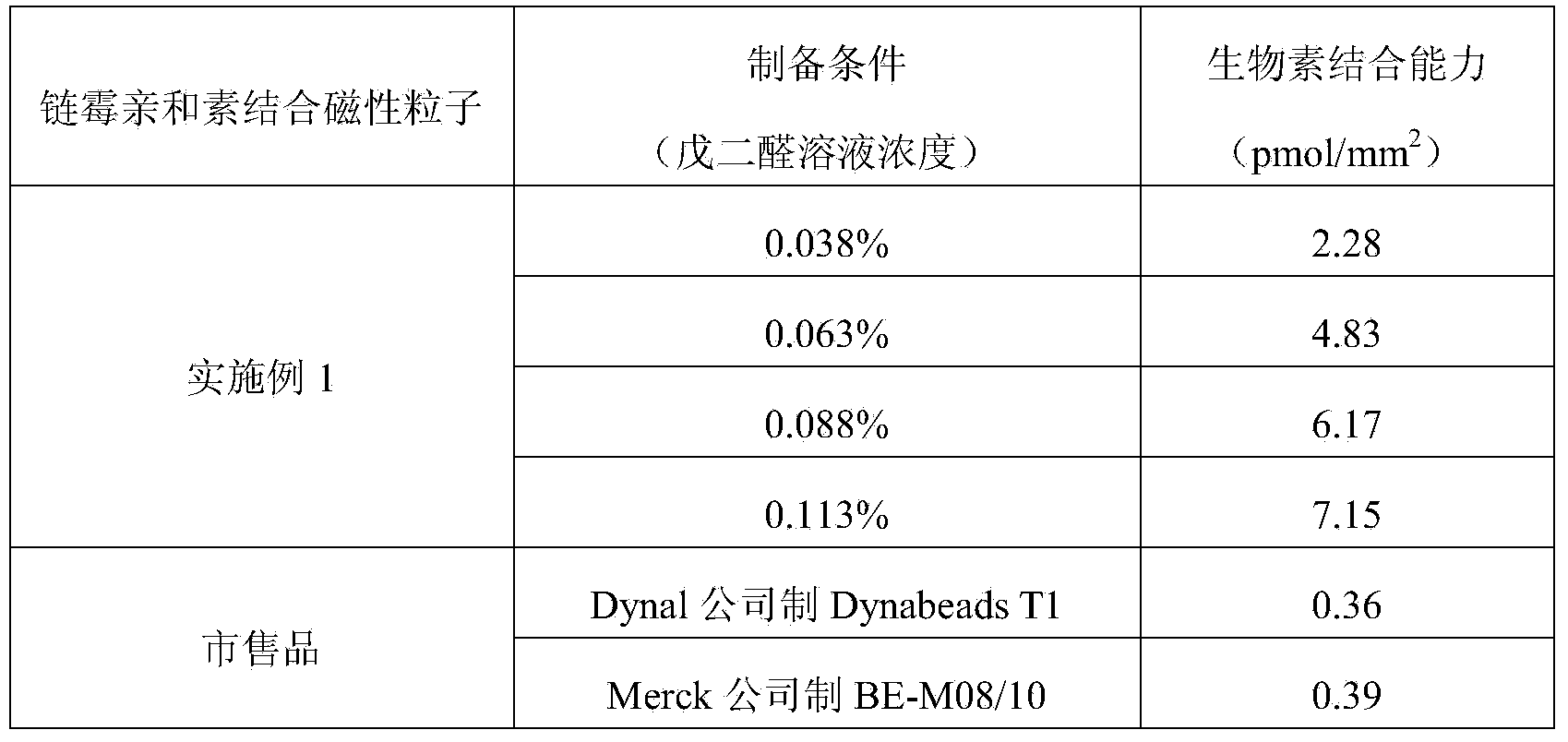

[0199] (1) Manufacture of streptavidin-conjugated magnetic particles

[0200] As the magnetic particles, amino-type Estapor magnetic particles EM2-100 / 40 (manufactured by Merck) were used. The magnetic particle is composed of a core-shell structure with a particle size of 1.62 μm, the inner core part contains a magnetic substance with a total mass ratio of 41.2%, and the shell part composed of polystyrene is chemically modified with amino groups at a rate of 97 μeq / g. particle. 2 mg of the magnetic particles were collected, and a pH 5.5, 10 mmol / L acetate buffer (hereinafter referred to as dispersion A) containing 1.0% of Trimethylstearylammonium Chloride (manufactured by Tokyo Chemical Industry Co., Ltd.) was added. 4mL to disperse it. Next, a powerful magnet is placed on the side of the container to collect the magnetic particles and remove the dispersion A by suction (hereinafter, the series of operations of adding the dispersion, collecting the magnetic particles, and su...

Embodiment 2

[0212] Analysis of the Crosslinked Structure of Streptavidin on Magnetic Particles

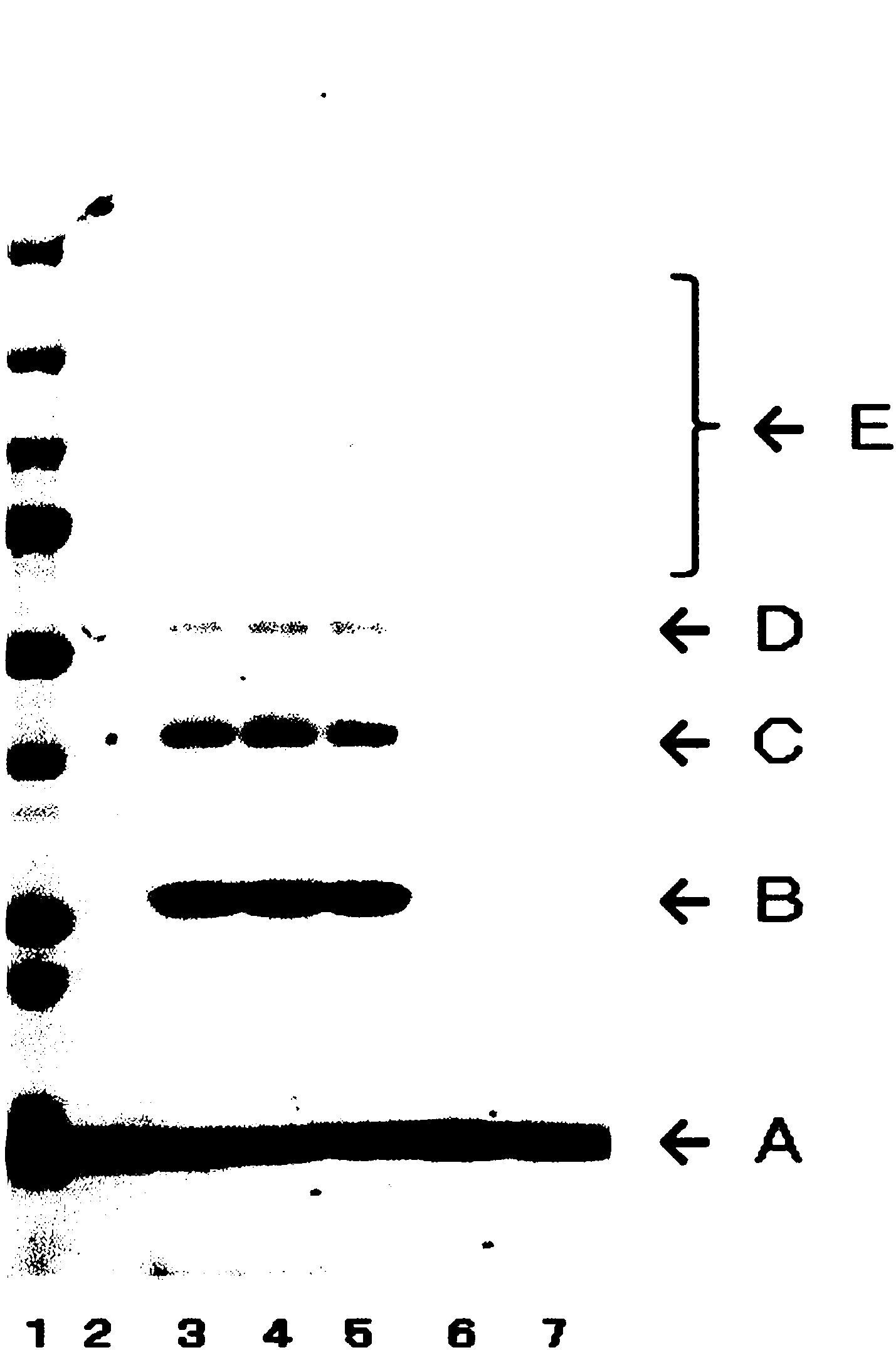

[0213] For the biotin binding capacity obtained by the same method as that of Example 1 is 2.61 pmol / mm 2 、4.95pmol / mm 2 、6.76pmol / mm 2 Each streptavidin-bound magnetic particle was washed 10 times with 4 mL of PBS, replaced with 1% SDS / PBS, and incubated at 60°C for 1 hour. Next, the magnetic particles were collected by a magnet, and the protein solution in the supernatant was collected and analyzed by SDS-PAGE. The same operation was also performed on commercially available streptavidin-conjugated magnetic particles. The results of SDS-PAGE are shown in figure 1 .

[0214] Such as figure 1 As shown, in streptavidin and commercially available streptavidin-bound magnetic particles, only monomers constituting streptavidin can be seen, but in the streptavidin-bound magnetic particles of the present invention, In addition to monomers, dimers, trimers, tetramers and higher order bands can a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com