Disposable sterile operating mattress

A surgical mattress, a disposable technology, applied in the field of mattresses, can solve the problems of increasing the workload of nurses, polluting the body of patients, easy slippage of bed sheets, etc., and achieves the effects of novel structure, low cost, and easy mass production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

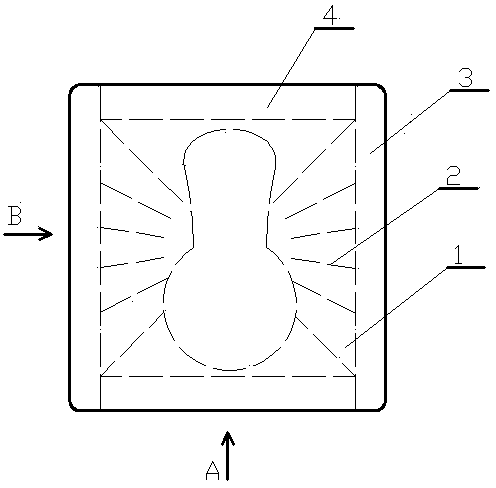

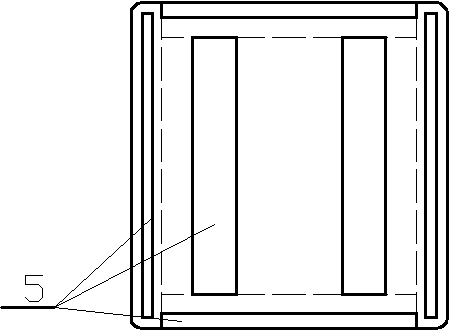

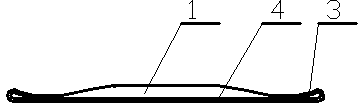

[0023] In the accompanying drawings, the disposable sterile surgical mattress includes a pad body 1, pad edges 4 connected to the front and rear sides of the pad body 1, and also includes anti-leakage drainage grooves 3 connected to both sides of the pad body 1 and located on the Adhesive strip 5 on the back of the pad body 1, the pad edge 4 and the anti-leakage drainage groove 3; the middle part of the pad body 1 is raised along its length direction to adapt to the curve of the human body; the surface of the pad body 1 is suppressed radioactively. The diversion groove 2, the diversion groove 2 points to the anti-leakage drainage groove 3; the pad body 1 is composed of a non-woven fabric layer 6 on the top surface, a PE film layer 9 on the bottom surface, and a polymer layer in the middle The water-absorbent resin layer 8, and the water-absorbent paper layer 7 respectively located between the non-woven fabric layer 6 and the polymer water-absorbent resin layer 8 and between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com