A method for extracting unsaponifiable matter from shea butter liquid oil

A technology of liquid oil and shea butter, which is applied in the direction of chemical instruments and methods, digestive system, biofuel, etc., can solve the problems of low content or purity of biologically active substances, improve nutritional application value, reduce cosmetic effects, and enhance functions sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0128] 1. Take 4Kg of refined shea olein with AV=0.5, triterpenoid alcohols and sterol content of 7.20%, add methanol and milk with a mass ratio (refined shea oil:methanol) of 3:1 Sodium methoxide with 0.7% quality of the fruit liquid oil, reacted at 70°C for 2.5 h, separated the liquid, took the upper liquid, washed with water, stood still to separate the liquid, took the upper liquid, and distilled under reduced pressure to remove the residual solvent to obtain the transesterification product. The yield was 92.0%, and the content of triterpene alcohols and sterols was 7.13%.

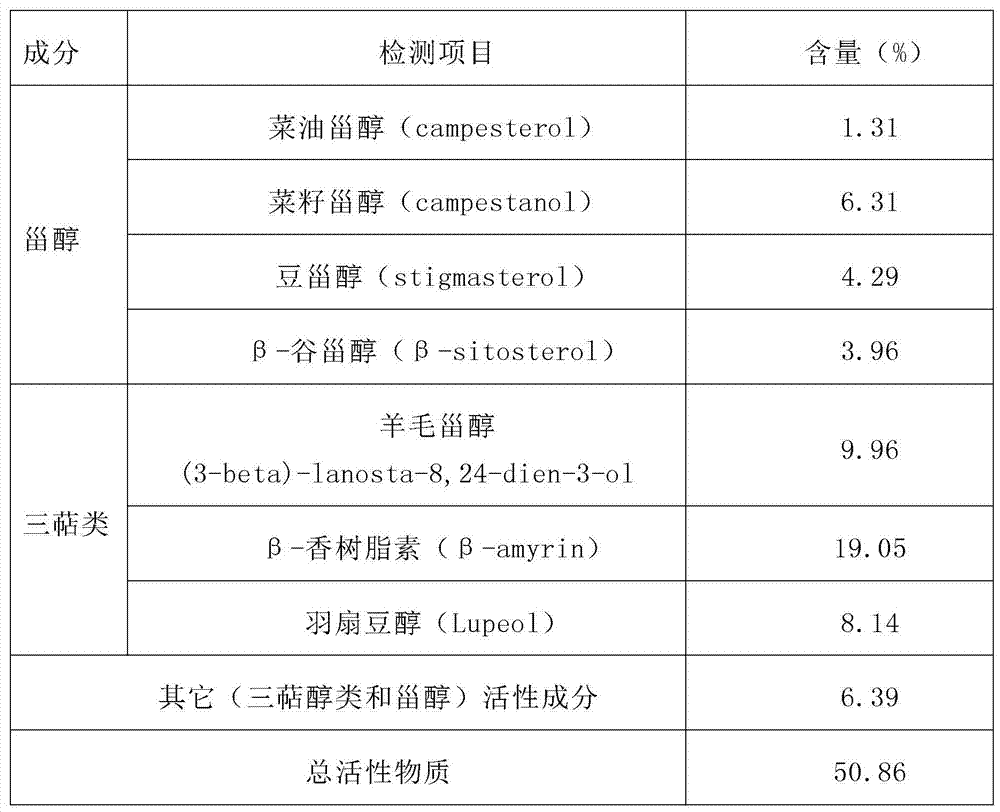

[0129] 2. Take 1kg of the shea olein transesterification product obtained in the previous step, and carry out molecular distillation at a distillation temperature of 110°C, a rotational speed of 250rpm, and a pressure of 10 -3 mbar. A 130 g heavy phase sample was obtained by distillation, and the content of triterpene alcohols and sterols was 50.86%. (The specific content of unsaponifiable matter in ...

Embodiment 2

[0139] 1. Take 4Kg of refined shea olein with AV=0.5, triterpenoid alcohols and sterol content of 7.20%, add methanol and milk with a mass ratio (refined shea oil:methanol) of 3:1 Sodium methoxide with 0.7% mass of fruit liquid oil, reacted at 70°C for 2.5 h, separated the liquid, took the upper liquid, washed with water, stood still to separate the liquid, took the upper liquid, and distilled under reduced pressure to remove the residual solvent to obtain the transesterification product, The yield was 92.0%, and the content of triterpene alcohols and sterols was 7.13%.

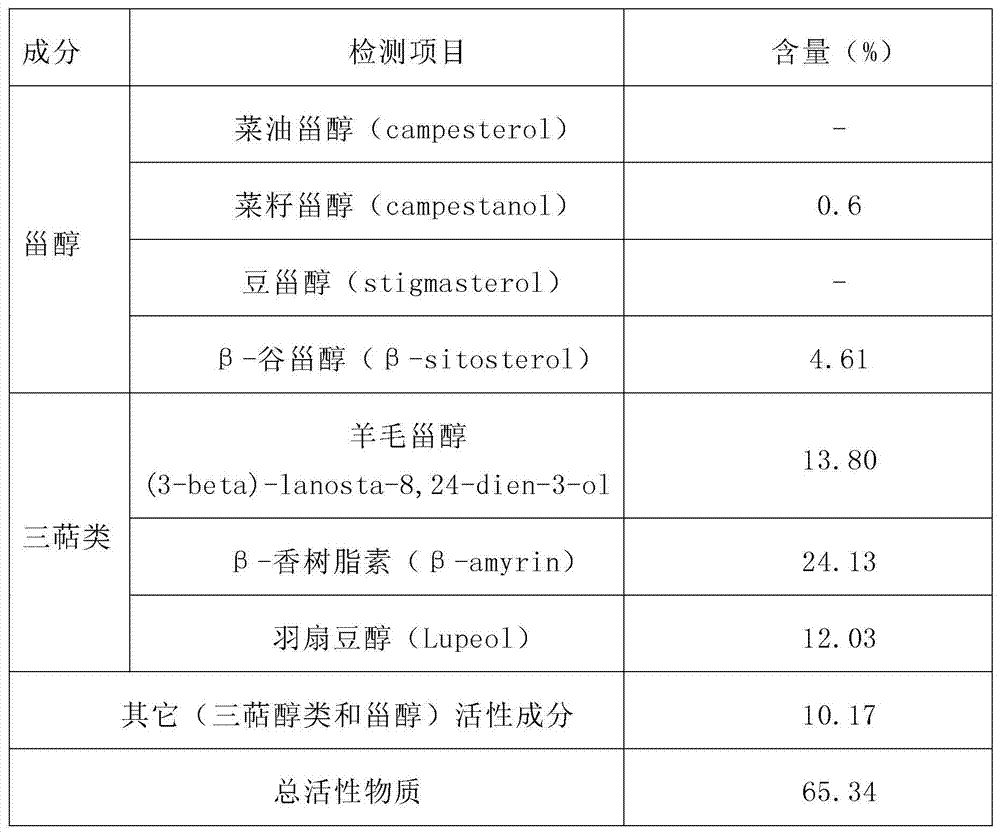

[0140] 2. Take 1kg of the shea olein transesterification product obtained in the above steps, and carry out molecular distillation at a distillation temperature of 110°C, a rotation speed of 250rpm, and a pressure of 10 -3 mbar. A 130 g heavy phase sample was obtained by distillation, and the content of triterpene alcohols and sterols was 50.86%. (The specific content of unsaponifiable matter in molecular d...

Embodiment 3

[0147] 1. Take 4Kg of refined shea olein with AV=0.5, triterpenoid alcohols and sterol content of 7.20%, add methanol and milk with a mass ratio of 3:1 (refined shea oil:methanol) Sodium methoxide with 0.7% mass of fruit liquid oil, reacted at 70°C for 2.5 h, separated the liquid, took the upper liquid, washed with water, stood still to separate the liquid, took the upper liquid, and distilled under reduced pressure to remove the residual solvent to obtain the transesterification product, The yield was 92.0%, and the content of triterpene alcohols and sterols was 7.13%.

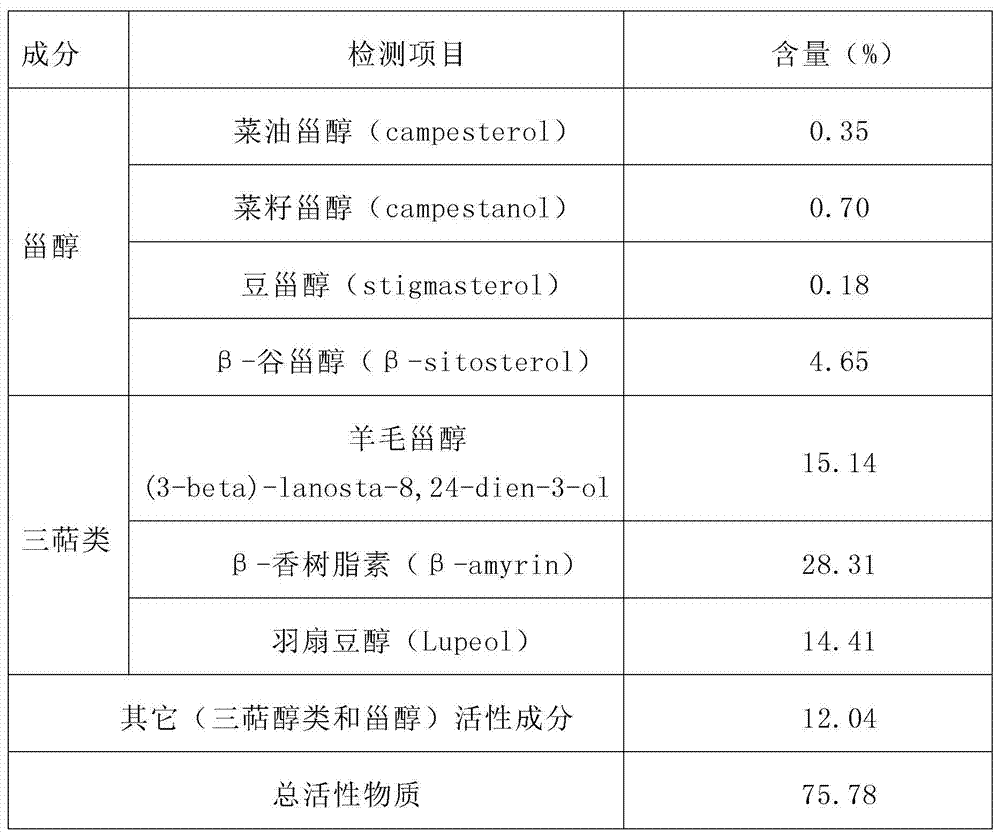

[0148] 2. Take 1kg of the shea olein transesterification product obtained in the previous steps, and carry out molecular distillation at a distillation temperature of 110°C, a rotational speed of 250rpm, and a pressure of 10 -3 mbar. A 130 g heavy phase sample was obtained by distillation, and the content of triterpene alcohols and sterols was 50.86%. (The specific content of unsaponifiable matter in the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com