Band sawing machine for cutting waste lead-acid storage batteries

A lead-acid battery, band sawing machine technology, applied in sawing machine equipment, metal sawing equipment, metal processing equipment and other directions, can solve the problems of increasing the difficulty of separation and recycling, reducing the service life of equipment, endangering people's health, etc., to avoid equipment The effect of loss and environmental pollution, improving recovery rate, reducing environmental pollution and recycling cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

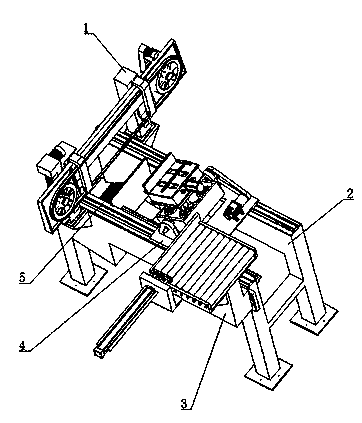

[0038] The utility model relates to a band saw machine for cutting waste lead-acid batteries. Said band sawing machine is as figure 1 Shown: including sawing device 1, sawing machine bed 2, pushing device 3, feeding device 4 and mesh screen 5. A sawing device 1 is fixedly installed near the left end of the sawing machine bed 2, a mesh screen 5 is installed on the inner side of the sawing machine bed 2 below the sawing device 1, and a pushing device is installed on the outer wall near the right end of the sawing machine bed 2 3. A feeding device 4 is movable on the bed 2 of the sawing machine.

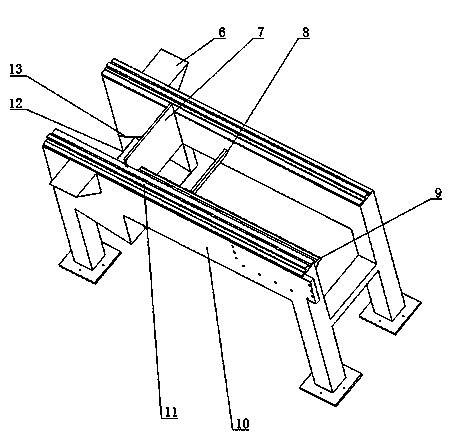

[0039] The specific structure of the saw bed 2 is as follows: figure 2 As shown: the sawing machine bed 2 includes a sawing mechanism seat 6, a vertical baffle plate 7, a blanking vibration beam 8, a rack 9, a sawing machine base 10, a feeding slide rail 11, an inclined plate 12 and an arc curved groove 13. The outer wall near the left end of the sawing machine base 10 is symmetric...

Embodiment 2

[0052] The utility model relates to a band saw machine for cutting waste lead-acid batteries. Except following technical parameter, all the other are with embodiment 2.

[0053] The distance between the vertical baffle 7 and the center line of the sawing mechanism seat 6 is 450-550 mm; the distance between the blanking vibration beam 8 and the vertical baffle 7 is 600-800 mm.

[0054] The length of the mesh screen 5 is 120-150mm longer than the arc length of the arc-shaped curved groove 13; the width of the mesh screen 5 is 90mm-100mm wider than the inside width of the sawing machine bed.

[0055] The trolley motor 24 is a servo motor; the turning motor 30 is a servo motor.

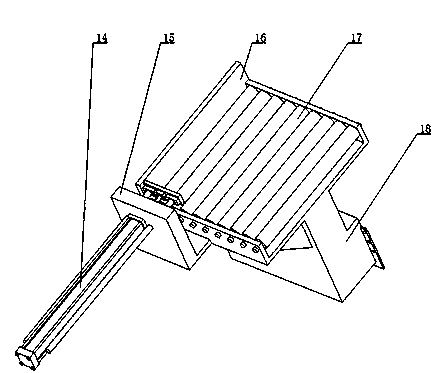

[0056] The operation process of this specific embodiment is: the initial position of the feeding device 4 when not working is that the axis of the turning shaft 32 and the axis of the pushing cylinder 14 on the pushing device 3 are located on the same vertical plane. When the waste lead-acid battery is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com