Butt welding tool for C-shaped beam of port stacking machine

A stacker and port technology, applied in the field of port stacker C-beam tailor welding tooling, can solve the problems of hardened layer damage on the steel plate surface, affect the mechanical properties of finished products, increase processing hours, etc., to ensure mechanical properties, Good straightness, saving production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

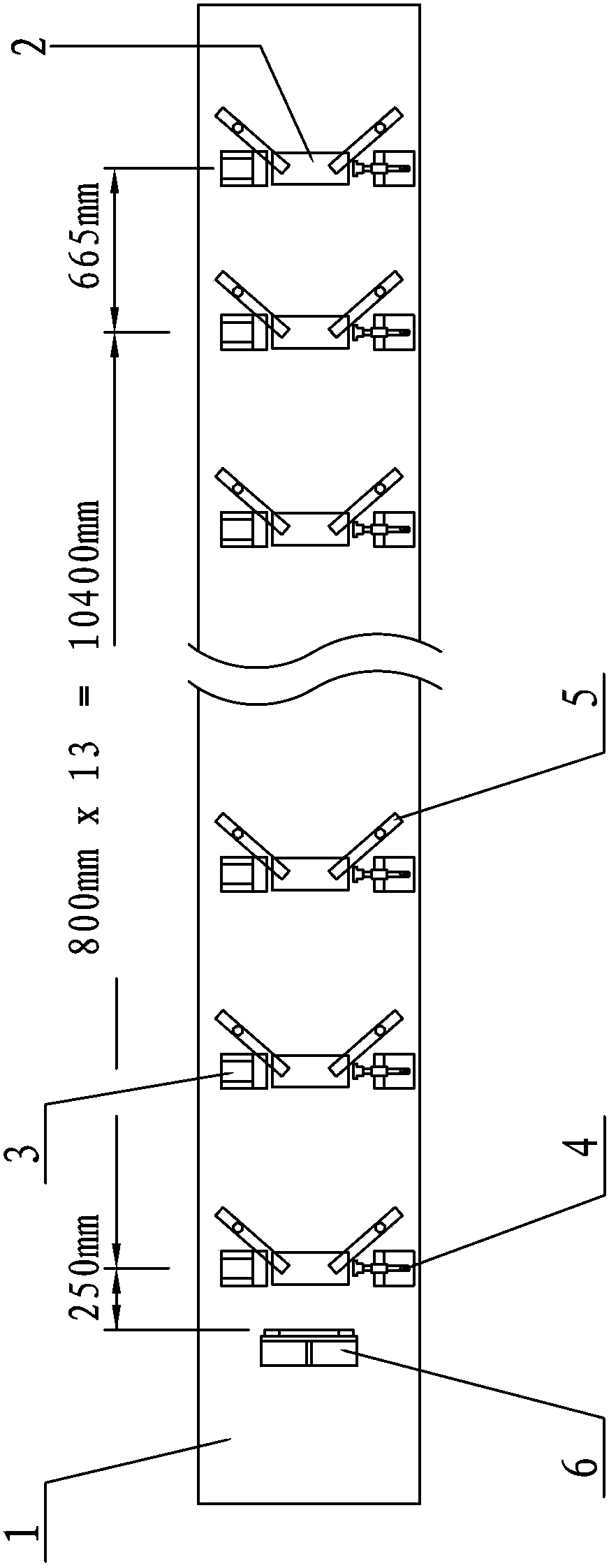

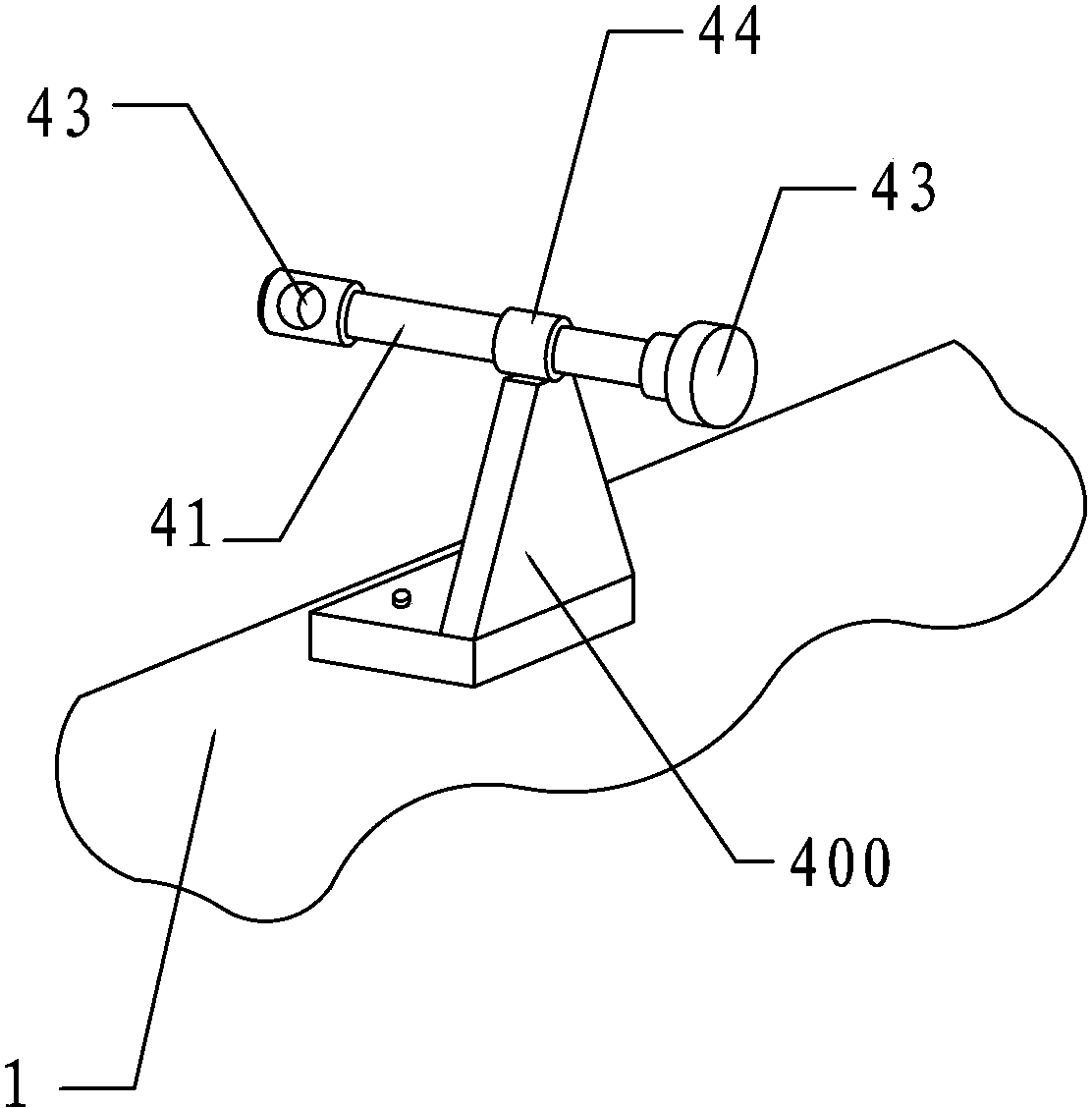

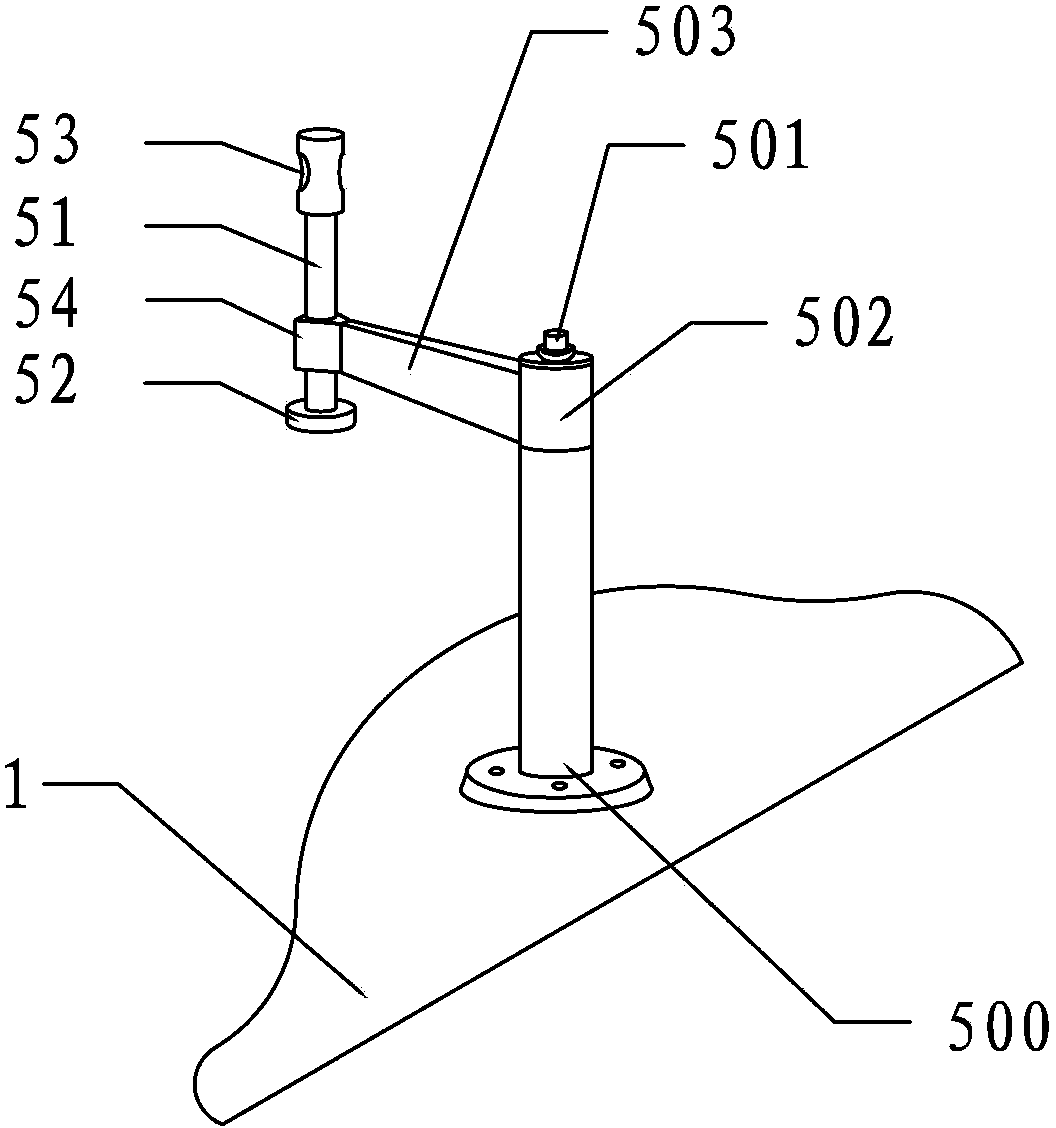

[0017] The invention provides a C-beam tailor-welding tool for a port stacker. The total length of the C-beam is 11385mm, the opening size is 250mm, the internal height is 80mm, and the plate is made of a steel plate with a thickness of 20mm. Such as figure 1 As shown, the C-beam tailor welding tooling of the port stacker includes a platform 1 on which 14 positioning and clamping devices are arranged in a line. Wherein, the 1st to 13th consecutive positioning and clamping devices on the left are distributed in an array, and the column offset value is 800mm. The fourteenth positioning and clamping device is correspondingly arranged at the tail end of the C-shaped beam, and is used for positioning and clamping the tail end of the C-shaped beam. Specifically, in this embodiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com