A Processing Technology of Precision Gap Adjusting Gasket

A technology of gap adjustment and processing technology, applied in the field of processing technology of precision gap adjustment gaskets, can solve the problems of inability to transform easily, expensive, poor humanization, etc., to avoid cost investment, meet market needs, and low cost control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention is further described below.

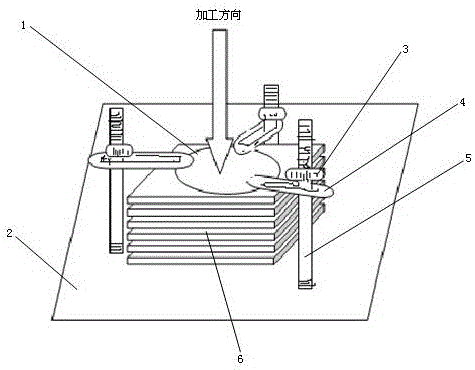

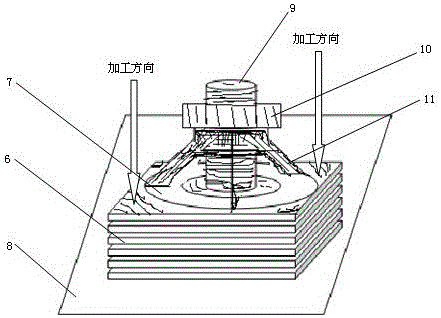

[0033] The invention provides a processing technology for a precision gap adjusting gasket, comprising the following steps:

[0034] ⑴Choose the overall lamination of raw materials, record the thickness of lamination and select the cutting tool;

[0035] T=To*Q

[0036] Among them: T is the optimal stacking thickness, To is the thickness required by the processing material, Q is the number of optimal stacking parts, and Lo is the optimal processing blade length;

[0037] Lo=1 / 3*L, L is the processing tool length;

[0038] For example, at present, it is necessary to process precision gaskets with a thickness of To = 0.03mm, and the standard knife length L = 100MM, and the effective length of the knife edge Lo = 33mm.

[0039] According to the formula T=To*Q, Q=T / To (theoretical value T=Lo) can be calculated; but in general, T

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com