New Machining Technology of Transmission Shaft Sliding Fork

A sliding fork and transmission shaft technology, which is applied in metal processing equipment, manufacturing tools, milling machine equipment, etc., can solve the problem of uneven force on the root of the two lugs of the sliding fork, inconsistent wall thickness difference between the two fork lugs, and excessive initial value of dynamic balance. Poor and other problems, to achieve the effect of reducing equipment requirements, reducing processing area, and accurately positioning benchmarks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

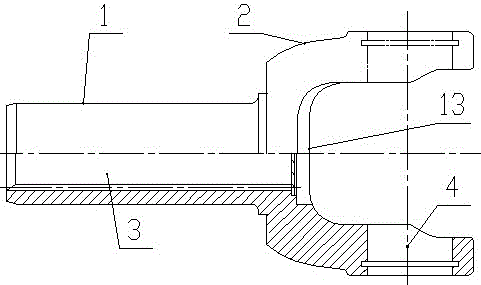

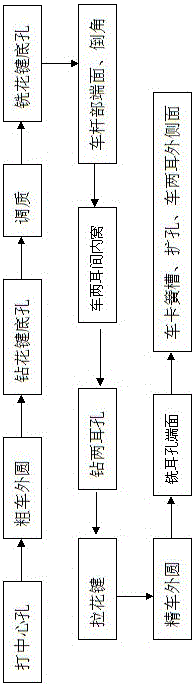

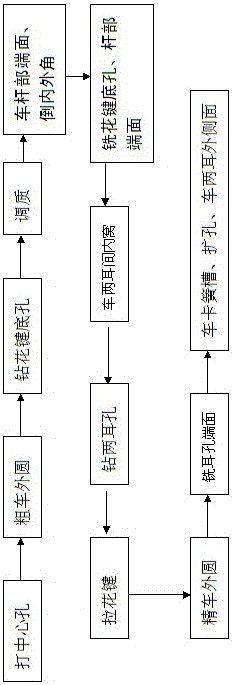

[0037] Such as figure 1 , image 3 , Figure 4 with Figure 5 As shown, the new processing technology of transmission shaft sliding fork of the present invention comprises the following steps:

[0038] (1), punch the center hole of the rod end face of the sliding fork;

[0039] (2) Based on the center hole, the outer circle of the rod part 1 is roughly turned;

[0040] (3) Based on the outer circle of the rod part 1 of the sliding fork, drill the spline bottom hole 3;

[0041] (4) Refining and tempering the entire sliding fork;

[0042] (5) Based on the outer circle of the rod part 1, the end face of the rod part 1 of the sliding fork is chamfered with inner and outer corners;

[0043] (6) Based on the outer circle of the rod part 1, use a compound tool to mill the spline bottom hole 3 first, and then process the end face of the rod part 1;

[0044] (7) Based on the outer circle of the rod part 1, the inner socket 13 between the ear parts 2 of the two forks of the car; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com