Kiwi fruit picking end actuator

A technology of end effector and kiwi fruit, which is applied in the direction of picking machines, manipulators, program control manipulators, etc., can solve the problems of complex structure design and control of end effectors, and restrictions on picking adjacent fruits, so as to achieve non-destructive picking, simplify the mechanical structure and Control and improve the effect of control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

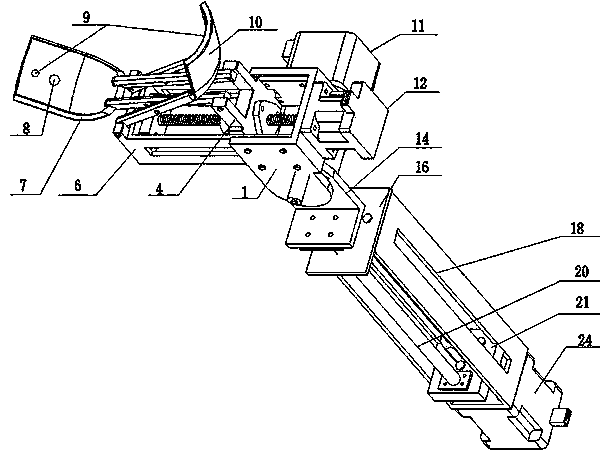

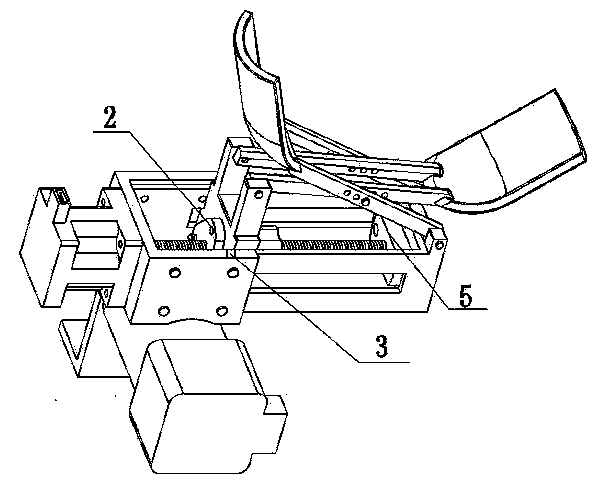

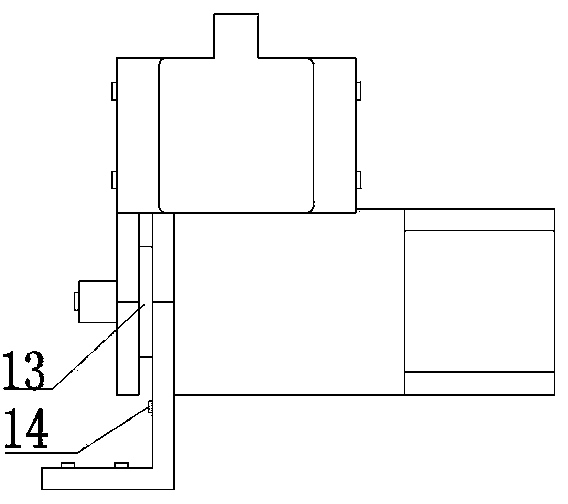

[0024] see figure 1 with figure 2 , a kiwifruit fruit picking end effector, which is composed of a clamping mechanism, a rotating picking mechanism, an approaching mechanism, a sensing system and a control system. The clamping mechanism includes a connecting piece I1, a Hall position sensor I3, and a horizontal slider 4 , Bracket I6, front finger 7, rear finger 10, linear stepper motor I12.

[0025] The clamping mechanism includes a front finger 7 and a rear finger 10 forming a scissors structure, the front finger 7 and the rear finger 10 are connected by pins, the other end of the front finger 7 is connected to the horizontal slider 4 by a pin, and the other end of the rear finger 10 is It is connected with the support I6 by pins, and the horizontal slider 4 is connected with the linear stepping motor I12 through the nut I2, and moves horizontally in the slide rail of the support I6; the inner sides of the front and rear fingers are lined with silica gel.

[0026] The rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com